A kind of luminous rope and its preparation method

A technology of luminescent rope and luminous body, which is applied in the direction of coating, textiles, papermaking, textile cables, etc. It can solve the problems of poor light resistance of polypropylene fiber, falling of luminescent powder, and short service life, etc., and achieves long service life, soft strength, The effect of long flex life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

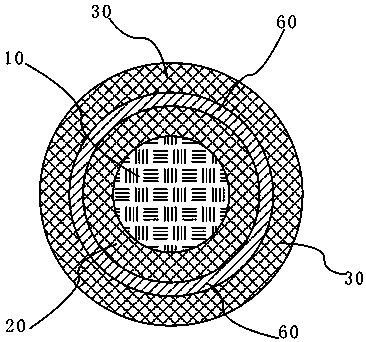

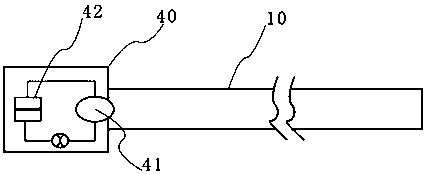

[0029] like figure 1 , 3 As shown, this embodiment provides a light-emitting rope, including a rope core 20, a rope sheath 30 wrapped outside the rope core 20, a light-emitting component 40, and a light-guiding optical fiber 10, and the rope core 20 is braided and coated on the light-guiding optical fiber 10 In addition, the cross-sectional shape of the light guiding fiber 10 is circular. The rope core 20 is woven from high-strength fiber, preferably dyneema fiber.

[0030] In this embodiment, the rope sheath 30 is made of Kevlar fiber, nylon yarn, light storage yarn and reflective yarn composite cross-woven, and the rope sheath 30 and the rope core 20 are passed through a double-sided thermosetting adhesive net. 60, the light emitted by the light-guiding optical fiber 10 can penetrate through the pores of the double-sided thermosetting adhesive net 60, and the connection strength between the rope sheath 30 and the rope core 20 is enhanced to avoid delamination. The rope sh...

Embodiment 2

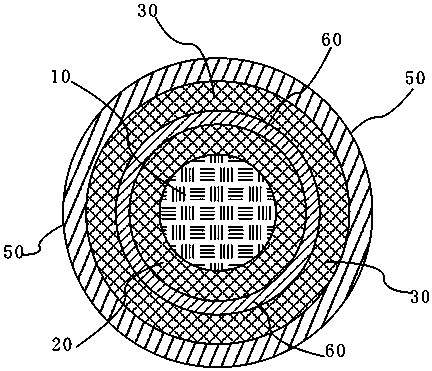

[0034] like Figure 2-3As shown, this embodiment provides a light-emitting rope, which is further improved on the basis of the above-mentioned technical solution: the rope skin 30 is also covered with a polyurethane transparent protective layer 50, through which the polyurethane transparent protective layer 50 gives the rope skin 30 and The rope core 20 has a good protective and anti-mildew effect, and at the same time endows the product of the present invention with excellent flexibility, enhances the structural stability between the strands of the rope sheath 30, and will not loosen after a certain part of the rope sheath 30 is cut under stress. Maintain good wrapping of the rope core 20 , acid and alkali resistance, aging resistance, good resilience and tension resistance, and reduce vibration damage to the light-guiding optical fiber 10 .

[0035] In this embodiment, the polyurethane transparent protective layer 50 is formed by stirring the following components uniformly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com