Method for making paper pulp from corn husks with one-pot method

A corn husk and pulp technology, which is applied in papermaking, pulp bleaching, textiles and papermaking, etc., can solve the problems of affecting the root system development of crops, not being suitable for returning to the field, and high fiber content, so as to achieve good whiteness stability and reduce emissions , high cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

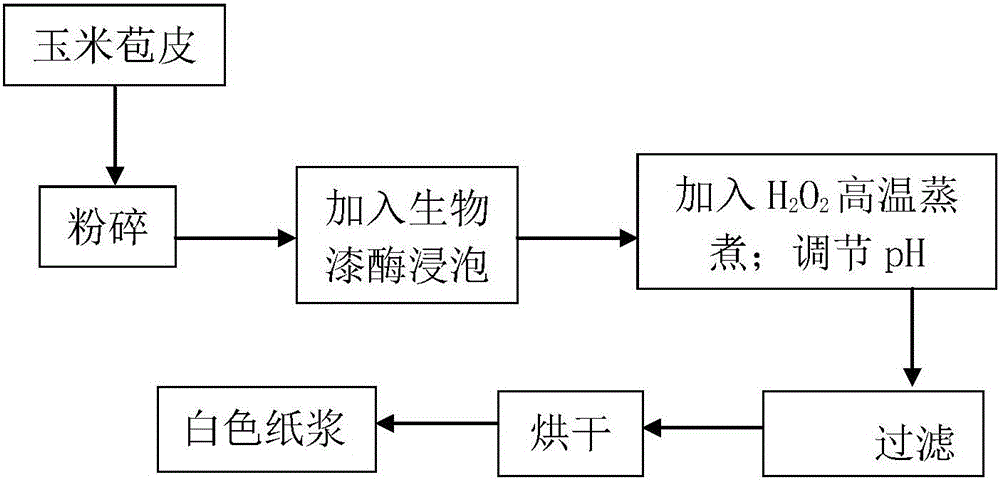

[0022] Such as figure 1 Shown, the present invention utilizes the method for the corn husk one-pot method to manufacture paper pulp, and the steps are:

[0023] a. Cut the fresh undried green corn husks into 3-5cm length segments, put them into a pulverizer and pulverize them for 10 seconds to obtain filamentous fine fibers with a length less than 1cm;

[0024] B. the maize husks after pulverizing are tiled in the reactor (reactors used in the present invention are all types of flat-bottomed heatable containers), adding a concentration of 20g / L biological laccase aqueous solution to the corn bracts The skin is just completely submerged, and the system is kept at 60°C for 24 hours;

[0025] c. adding volume in the reactor is 10% H of the total volume of material (i.e. biological laccase aqueous solution and corn husk immersed therein) in the reactor 2 o 2 As a bleaching agent, the mass is 0.3% MgSO of the total mass of the material in the reactor 4 and a mass of 3.0% Na of ...

Embodiment 2

[0029] Such as figure 1 Shown, the present invention utilizes the method for the corn husk one-pot method to manufacture paper pulp, and the steps are:

[0030] a. Cut the fresh undried green corn husks into 3-5cm length segments, put them into a pulverizer and pulverize them for 15 seconds to obtain filamentous fine fibers with a length less than 1cm;

[0031] B. the maize husks after pulverizing are tiled in the reactor (reactors used in the present invention are all types of flat-bottomed heatable containers), adding a concentration of 10g / L biological laccase aqueous solution to the corn husks in the reactor The skin is just completely submerged, and the system is kept at 50°C for 20 hours;

[0032] c. adding volume in the reactor is the total volume of 12% H of the material (i.e. biological laccase aqueous solution and corn husks immersed therein) in the reactor 2 o 2 As a bleaching agent, the mass is 0.4% MgSO of the total mass of the material in the reactor 4 and a ...

Embodiment 3

[0036] Such as figure 1 Shown, the present invention utilizes the method for the corn husk one-pot method to manufacture paper pulp, and the steps are:

[0037] a. Cut the fresh undried green corn husks into small sections with a length of 3-5cm, put them into a pulverizer and pulverize them for 20 seconds, and obtain filamentous fine fibers with a length of less than 1cm;

[0038] b. the maize husks after pulverizing are spread in the reactor (reactors used in the present invention are all types of flat-bottomed heatable containers), adding a concentration of 12g / L biological laccase aqueous solution to the corn bracts The skin is just completely submerged, and the system is kept at 55°C for 21 hours;

[0039] c. adding volume in the reactor is 15% of the total volume of material (i.e. biological laccase aqueous solution and corn husk immersed therein) in the reactor 2 o 2 As a bleaching agent, the mass is 0.5% MgSO of the total mass of the material in the reactor 4 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com