Sequential bleaching process suitable for ECF short-process bleaching

A short-procedure, sequential technology, applied in pulp bleaching, cellulose pulp post-treatment, textiles and papermaking, etc., can solve the problems of high waste water pollution load, high bleaching cost, large water consumption, etc. Simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Proceed as follows:

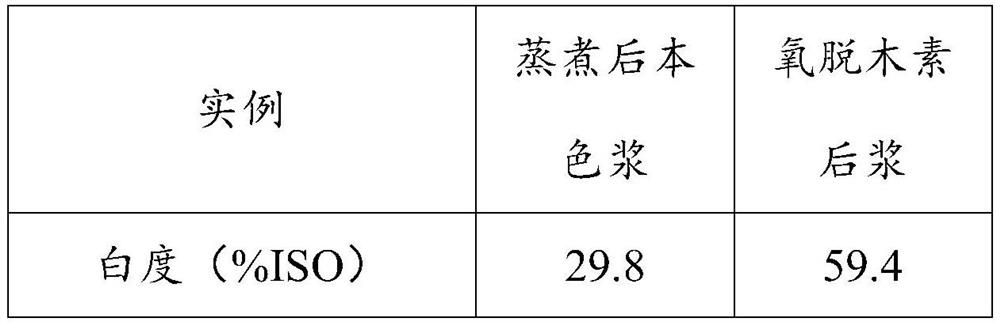

[0031] (1) The cooking condition of eucalyptus kraft pulp is: the amount of alkali used is 21% (relative to the absolute dry raw material NaO 2 ), the liquid ratio is 1:5, the degree of sulfidation is 25%, the cooking temperature is 170°C, a small degassing is carried out at 105°C, the heating time is 100min, and the holding time is 90min; after cooking, washing and screening are carried out to obtain unbleached kraft pulp .

[0032] (2) Oxygen delignification conditions are: adjust the pulp concentration to 10%, add NaOH consumption 3%, MgSO 4 The dosage is 0.6%, the oxygen pressure is 0.6Mpa, the temperature is 100°C, and the holding time is 60min; then washing is carried out to obtain oxygen delignified pulp.

[0033] (3) Papermaking: The natural color pulp after eucalyptus kraft cooking and the pulp after oxygen delignification were beaten to 35 ° SR respectively, and then the pulp fibers were decomposed in the defiberizer to make them evenly...

Embodiment 2

[0038] Proceed as follows:

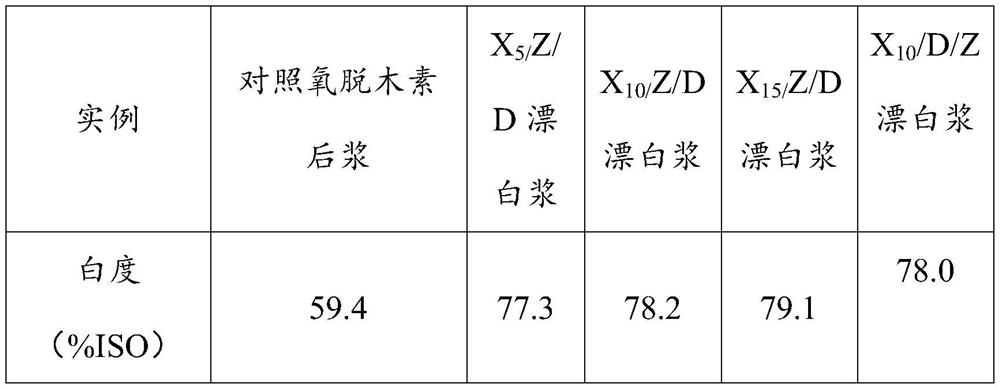

[0039] (1) X / Z / D or X / D / Z sequential bleaching: carry out sequential bleaching to the eucalyptus kraft pulp after oxygen delignification in embodiment 1, X is xylanase auxiliary bleaching; Z is ozone Bleaching; D is chlorine dioxide bleaching. The pulp is sequentially bleached with xylanase, ozone and chlorine dioxide without washing in between.

[0040] First, xylanase is used to assist bleaching of pulp, the process conditions are pulp concentration 10%, the dosage of xylanase is 5u / g, 10u / g, 15u / g, pH=5, bleaching temperature 55°C, bleaching The time is 60 minutes. Then carry out ozone bleaching, the process condition is pulp concentration 10%, pH=2, 55 ℃, bleaching time 5min, ozone consumption 1.0%, ethylene glycol consumption 2%. Finally, chlorine dioxide bleaching is carried out, and the process conditions are 10% pulp concentration, ClO 2 The dosage is 0.2%, the pH=2~3, the bleaching temperature is 55°C, and the bleaching time is 30min. ...

Embodiment 3

[0046] Proceed as follows:

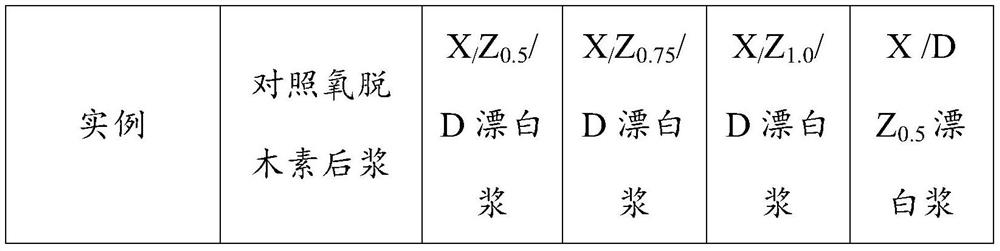

[0047] (1) X / Z / D or X / D / Z sequential bleaching: carry out sequential bleaching to the eucalyptus kraft pulp after oxygen delignification in embodiment 1, X is xylanase auxiliary bleaching; Z is ozone Bleaching; D is chlorine dioxide bleaching. The pulp is sequentially bleached with xylanase, ozone and chlorine dioxide without washing in between.

[0048] First, use xylanase to assist bleaching of paper pulp. The technological conditions are pulp concentration 12%, xylanase dosage 10u / g, pH=5, bleaching temperature 60°C, and bleaching time 60min. Then carry out ozone bleaching, the technological conditions are pulp concentration 10%, pH=2, 60 ℃, bleaching time 5min, ozone consumption is respectively 0.5%, 0.75%, 1.0%, ethylene glycol consumption 2%. Finally, chlorine dioxide bleaching is carried out, and the process conditions are 10% pulp concentration, ClO 2 The dosage is 0.3%, the pH=2.5, the bleaching temperature is 60°C, and the bleaching ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com