Patents

Literature

44results about How to "Reduce Bleaching Costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

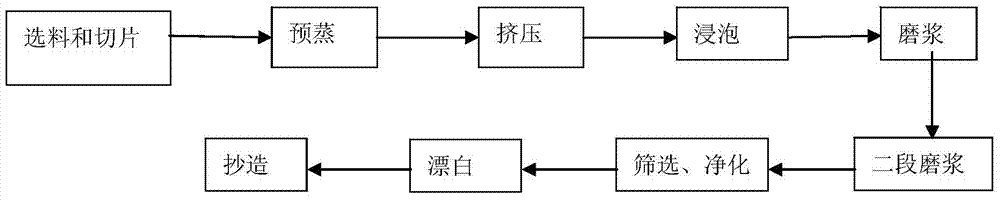

Method for preparing super-high-bulk paper pulp from fir slabs

ActiveCN104711884AReasonable useImprove toughnessPretreatment with water/steamPretreatment with alkaline reacting compoundsPulp and paper industryCompressibility

The invention discloses a method for preparing super-high-bulk paper pulp from fir slabs. The method is a process for producing bleached pulp boards according to the chemical hot-grinding technology, and comprises the following steps: slicing, pre-boiling, extruding, soaking, pre-heating, defibrination, secondary defibrination, screening and purifying, bleaching and papermaking. The method has the advantages that the prepared paper pulp is high yield, bulk, whiteness, drainability, tenacity, stiffness, ink absorption and compressibility, so that the print performance of the prepared paper pulp can be improved; the production cost and the sewage emission are low; the sewage is easy to treat; the prepared paper pulp can be used for producing of light paper, cup base paper and other types of paper requiring high bulk.

Owner:福建腾荣达制浆有限公司

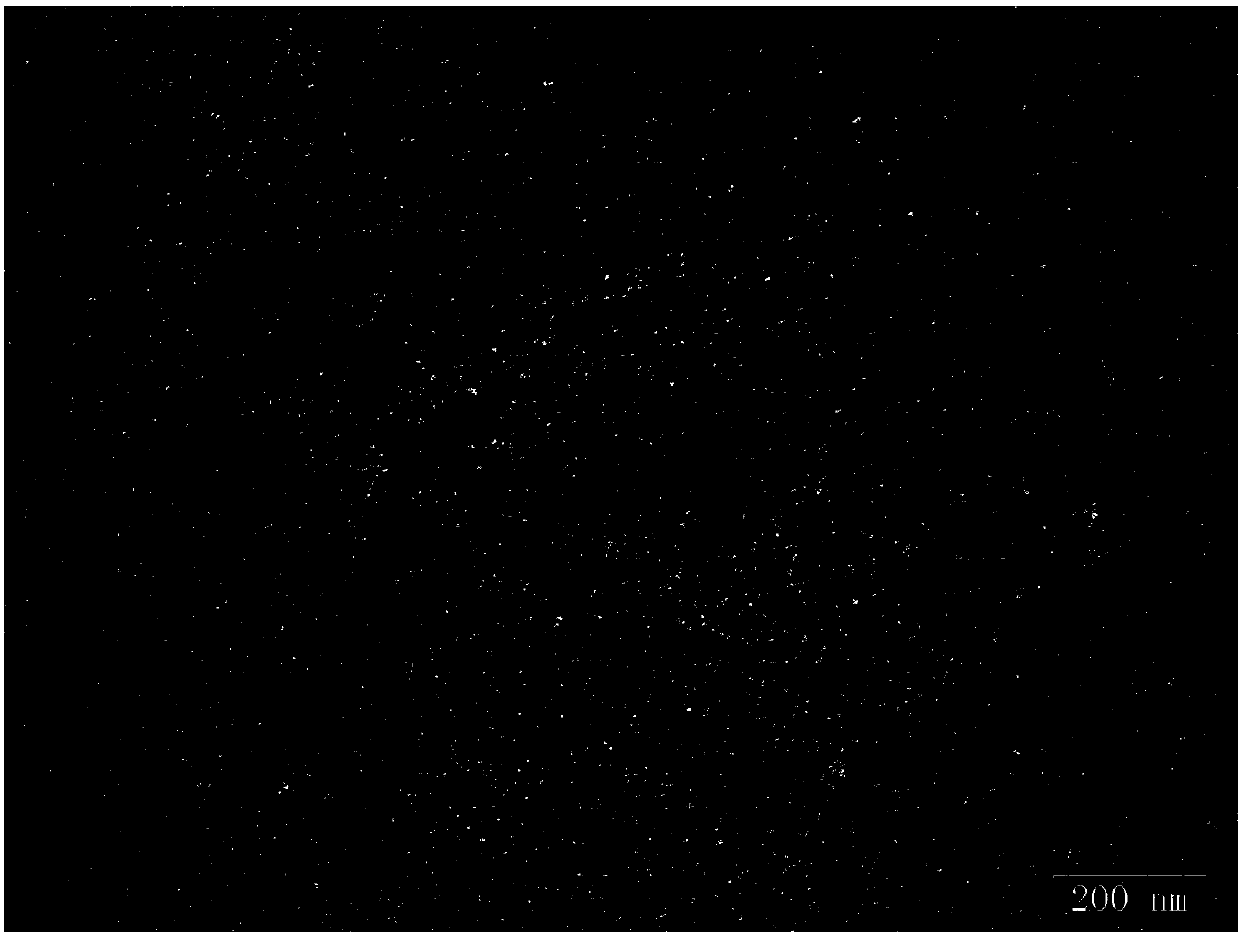

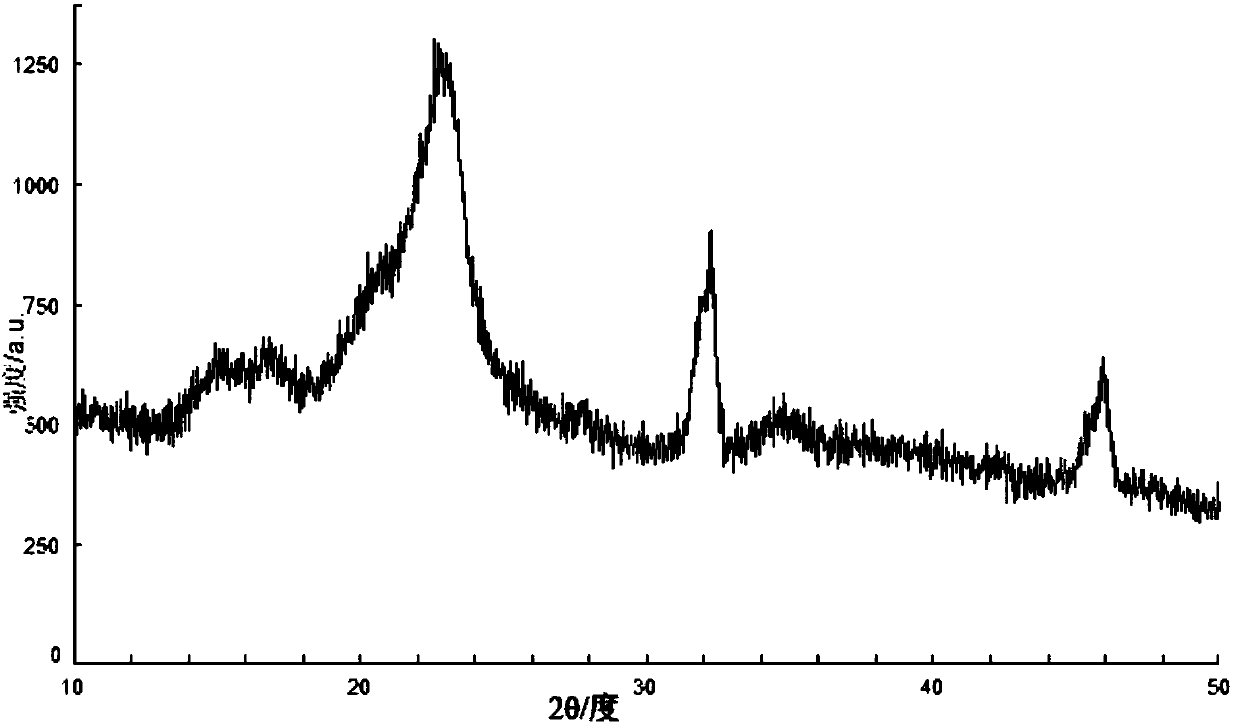

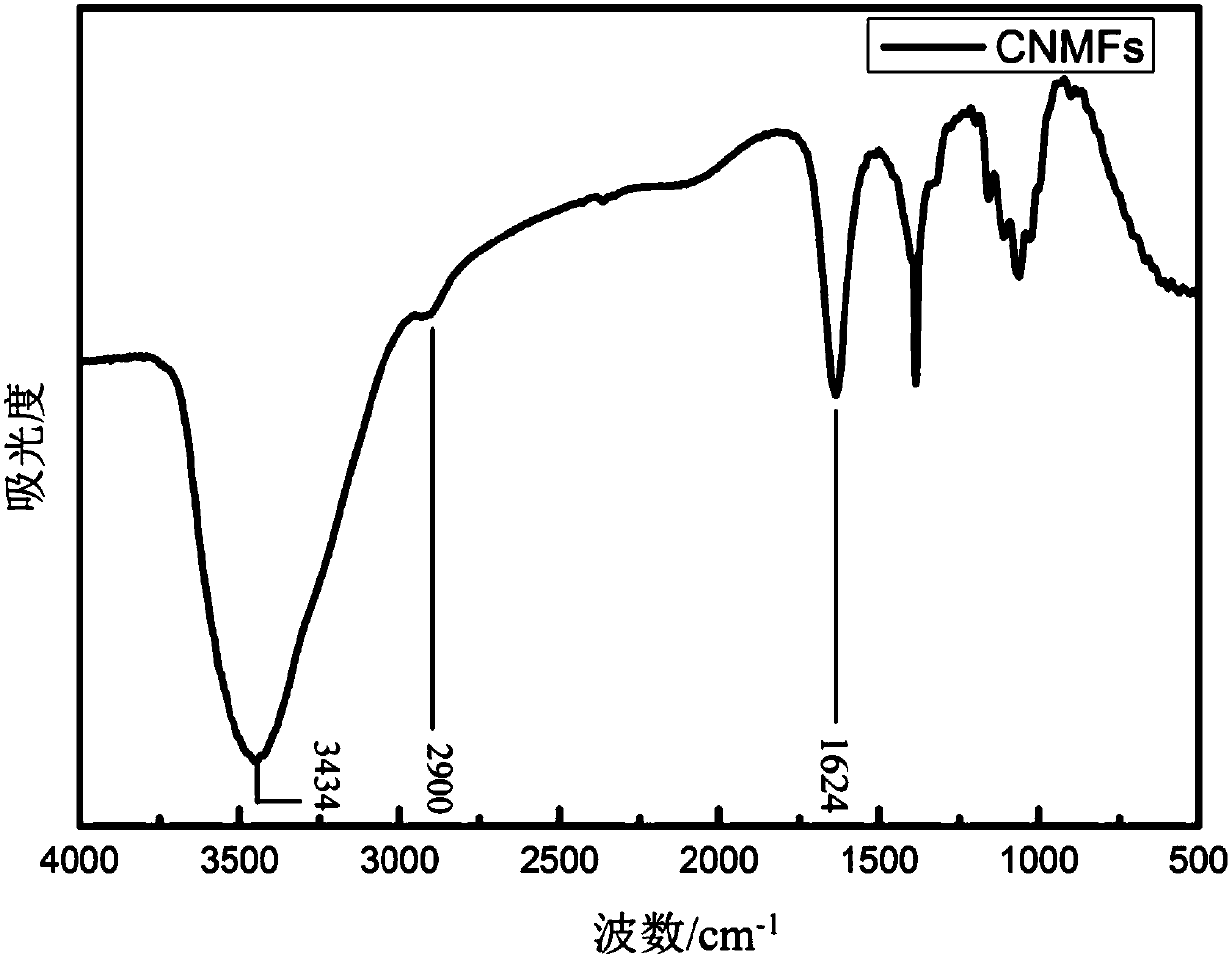

Clean preparation method of carboxymethyl nanocellulose material

ActiveCN107602709AImprove qualityReduce pollutionPaper material treatmentFiberCarboxymethyl cellulose

The invention relates to a clean preparation method of a carboxymethyl nanocellulose material. The clean preparation method is prepared by the following steps: pretreatment of nanocellulose raw materials, oxygen bleaching and pulping, continuous oxygen bleaching, bleaching, crushing and activation of the pulp, etherification, neutralization and purification and nanocrystallization. According to the clean preparation method, multiple straws and plant wastes are utilized as raw materials for clean pulping to prepare cellulose pulp and then prepare the carboxymethyl cellulose nanofiber, so that the range of raw materials for nanocellulose preparation is expanded, the process is simple and continuous, and environment-friendly and low cost effects are achieved, a new path for preparing the nanocellulose is opened up and wide prospect is provided for application of the nanocellulose. According to the clean preparation method, the cellulose can be used as the raw material to directly prepareand obtain functional nanocellulose fiber, the prepared modified nanocellulose contains carboxyl groups, has good degree of crystallinity, is small in crystalline grain and provides a good basis for later application of the product.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Bamboo filament bleaching process

ActiveCN103252815ASimple stepsReduce Bleaching CostsWood treatment detailsReed/straw treatmentChlorine dioxideSolid particle

The invention discloses a bamboo filament bleaching process, which comprises the steps of: S1) bamboo filament pretreatment: putting bamboo filaments into clear water and soaking them for 30min-1.5h, then getting them out and airing them for 10-40min; S2) bamboo filament bleaching, which comprises: S21) preparation of a chlorine dioxide bleaching solution, i.e. putting chlorine dioxide solid particles into clear water and stirring them evenly, with the chlorine dioxide solid particles and the clear water being in a weight ratio of 1.5-2.5:50; S22) placing the bundled skeins of bamboo filaments aired in S1 into the chlorine dioxide bleaching solution prepared in S21 in order and soaking them for 8-12h; and S3) getting out the bamboo filaments well soaked in S2, washing them 2-3 times, and airing them or drying them in the sun. The bamboo filament bleaching process provided in the invention has simple steps and a low bleaching cost, and has no need of heating, fumigation and other steps, thus having energy saving and environmental protection effects.

Owner:重庆知德文化传播有限公司

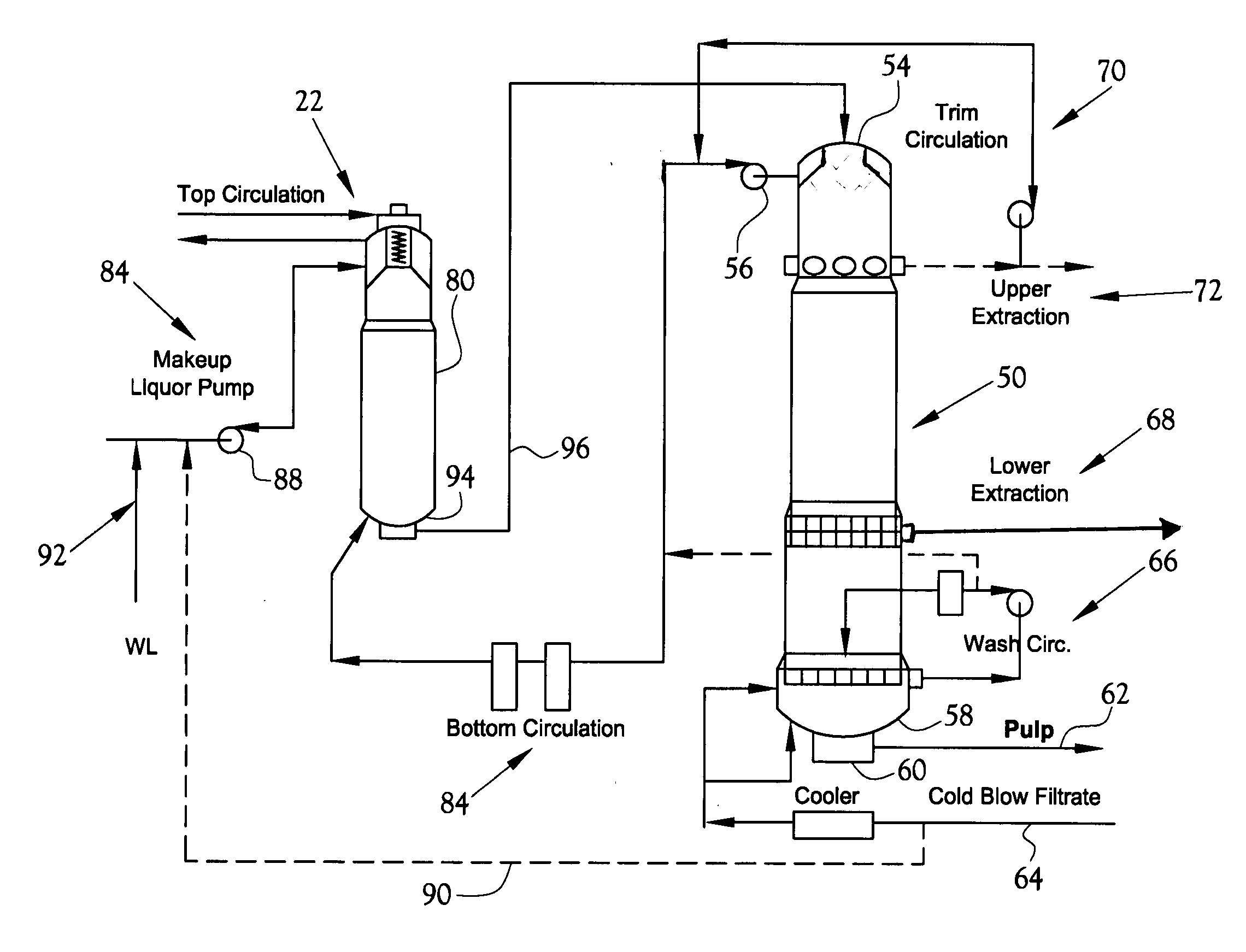

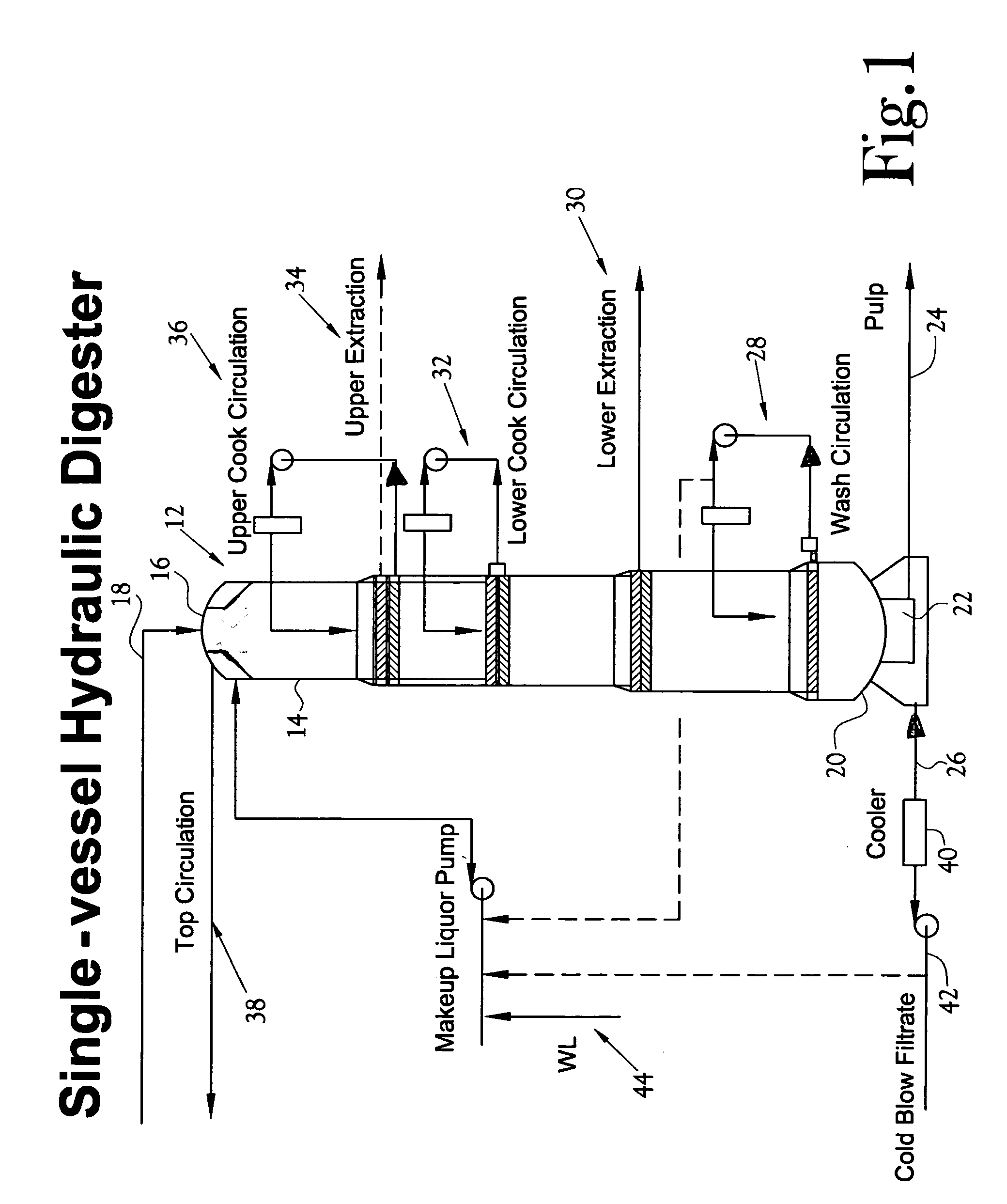

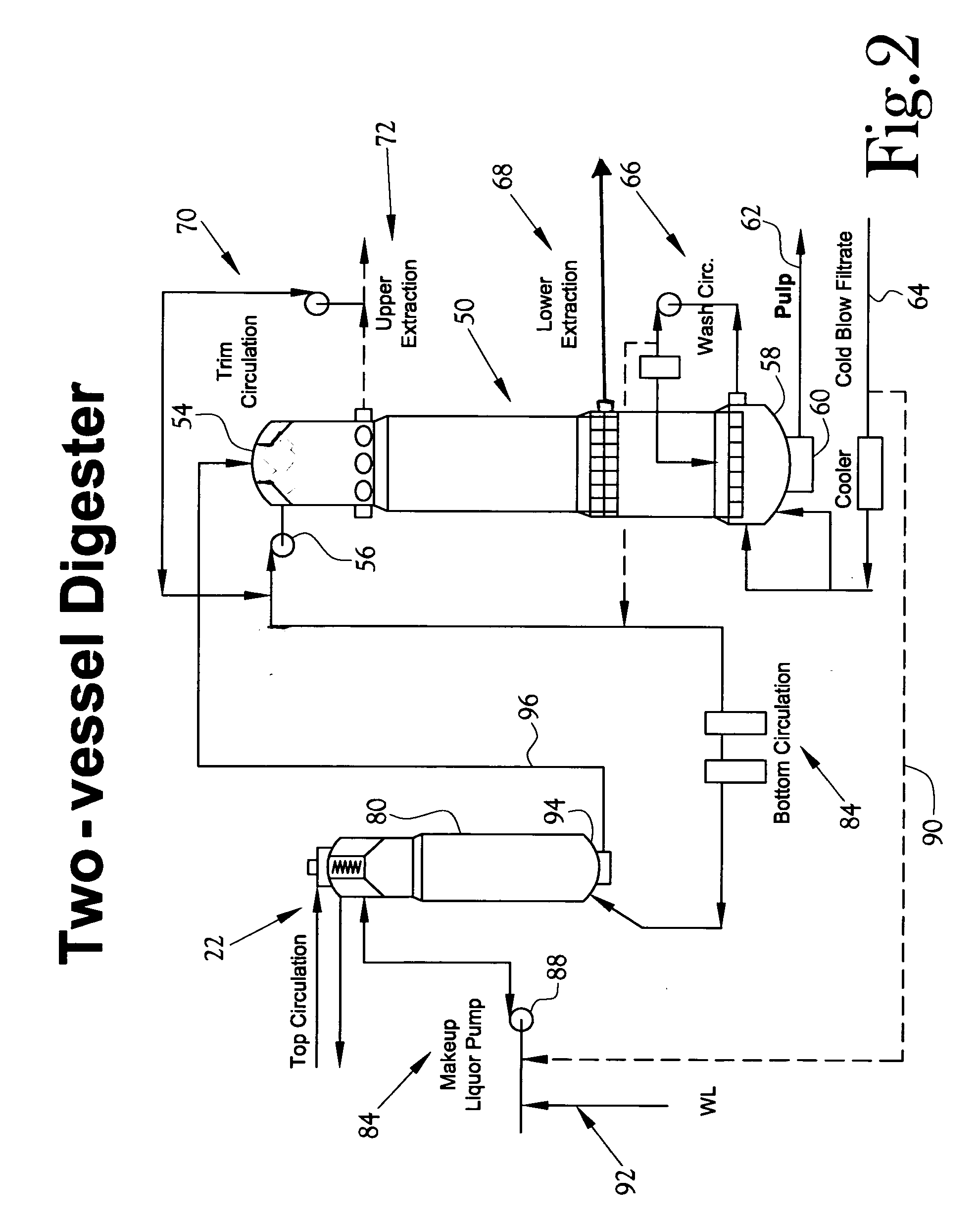

Methods to decrease scaling in digester systems

ActiveUS20050284592A1Reduced calcium carbonate scalingReduction in pulping energy requirementPulp liquor regenerationDigestersCalcium concentrationChemistry

One aspect of this invention relates to a method and digester for reducing the deposition of calcium-based scale in a wood chip digester including extraction from the digester of first and second quantities of cooking liquor having respective first and second calcium concentrations, treating the extracted cooking liquors to produce a cooking liquor having a calcium concentration less that the calcium concentration of the either of the first and second extracted cooking liquors, and, reintroducing the treated cooking liquor to the digester. Another aspect of this invention relates to a method and digester in which through put through the digester is increased by the continuous addition of process liquor into the digester preferably at an upper region of the digester.

Owner:INT PAPER CO

Process for producing bleached pulp

ActiveUS20090183845A1Good colorReduce Bleaching CostsWashing/displacing pulp-treating liquorsPulp bleachingCelluloseChlorine dioxide

Provided are a method for producing bleached pulp, comprising processing unbleached pulp obtained by cooking a lignocellulose substance, for alkali-oxygen bleaching followed by treatment with peroxomonosulfuric acid and thereafter by multistage chlorine-free bleaching treatment starting from chlorine dioxide treatment; a method for producing bleached pulp, comprising processing the unbleached pulp for alkali-oxygen bleaching followed by chlorine-free bleaching treatment or totally chlorine-free bleaching treatment to bleach it to a degree of brightness of from 70 to 89%, and further followed by treatment with peroxomonosulfuric acid; and paper produced by the use of the bleached pulp produced according to these production methods, at a papermaking pH of at most 6. Provided are the efficient production methods for bleached pulp in which the colour reversion resistance is enhanced in chlorine-free bleaching and the bleaching cost increase is prevented, and the paper produced by the use of the bleached pulp according to an acid papermaking process.

Owner:MITSUBISHI GAS CHEM CO INC

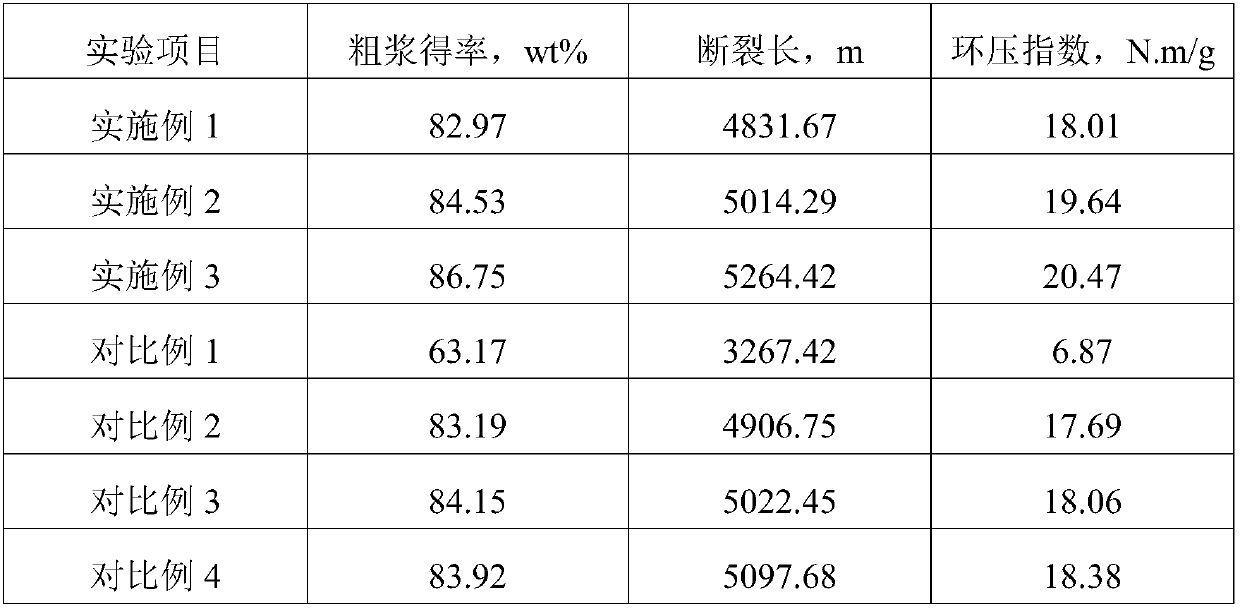

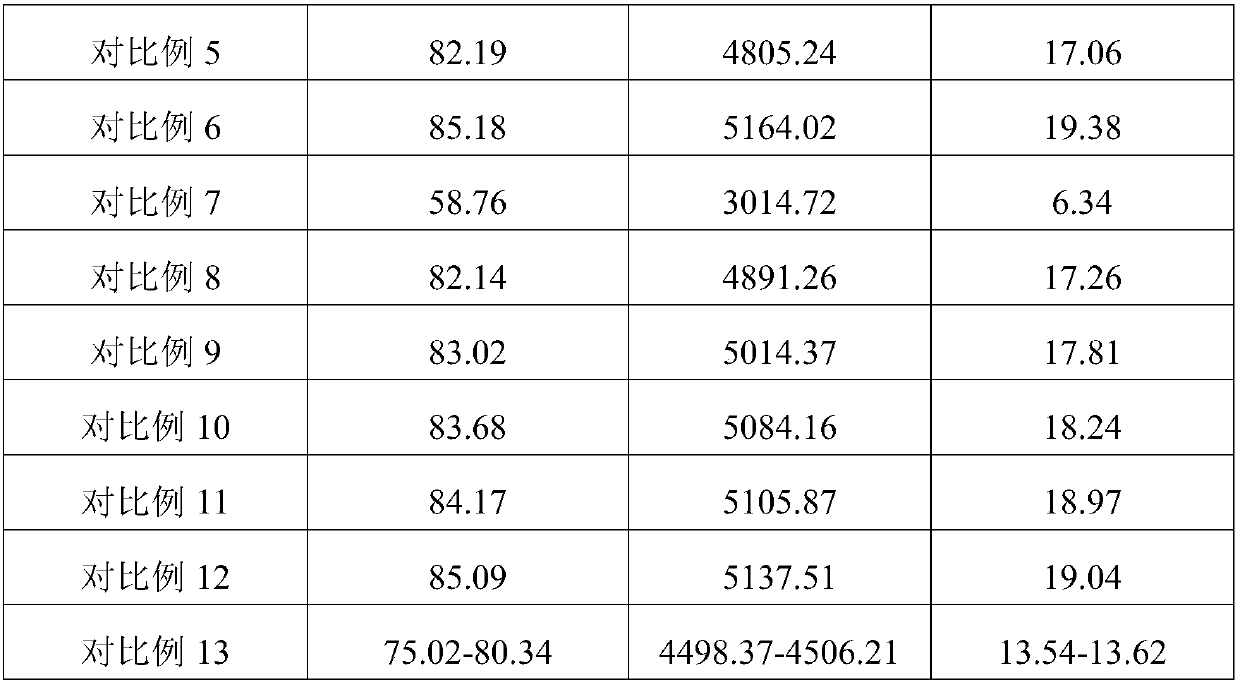

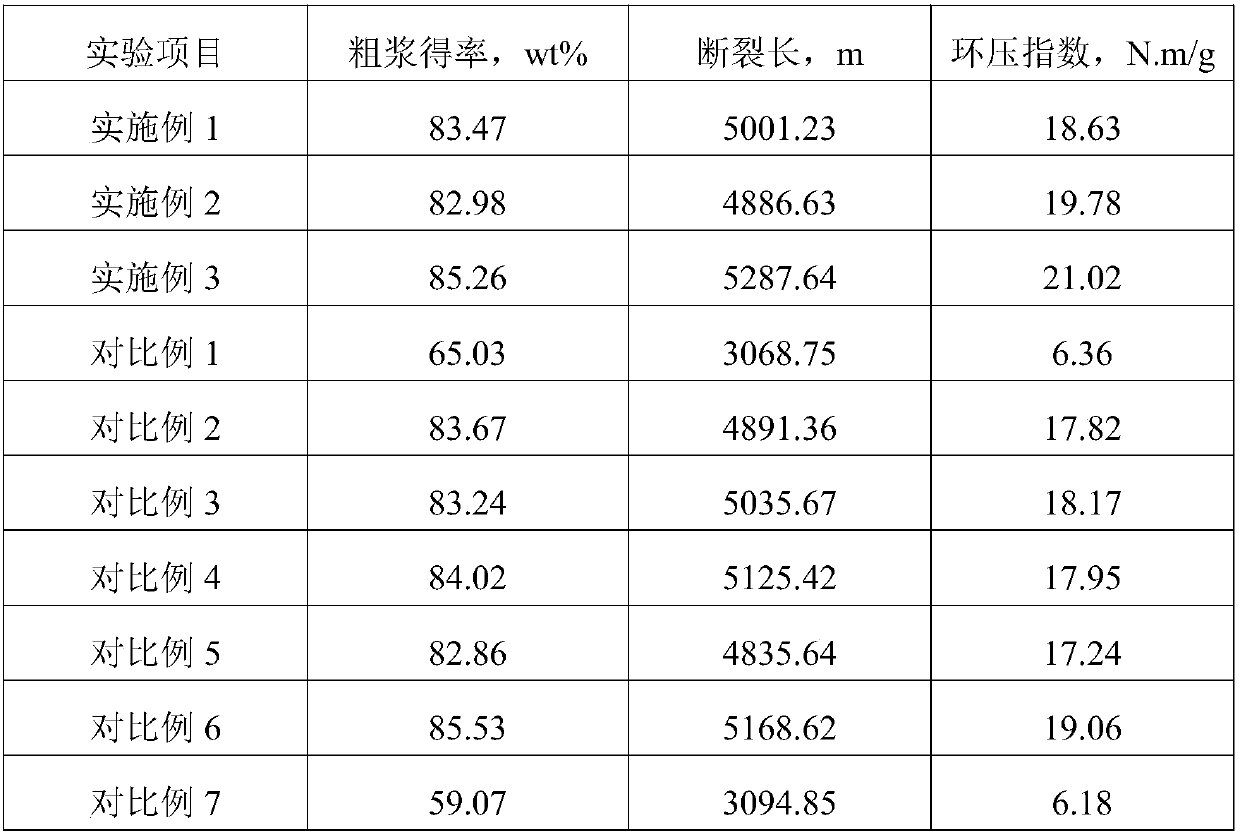

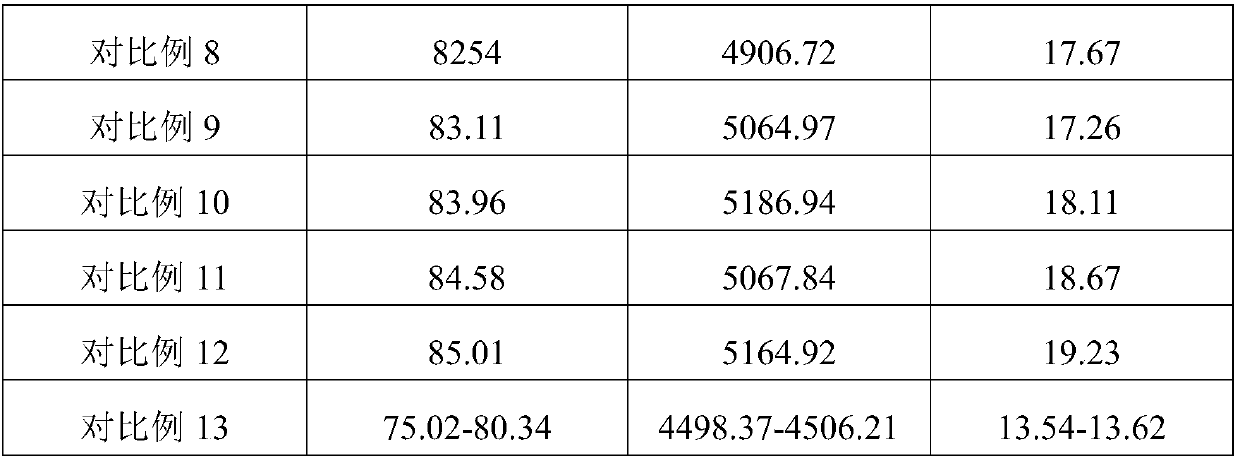

Preparation method of high-strength corrugated board

InactiveCN107700275APlay a role in penetrationAct as surface activePulping with inorganic basesPulping with organic solventsPapermakingEconomic benefits

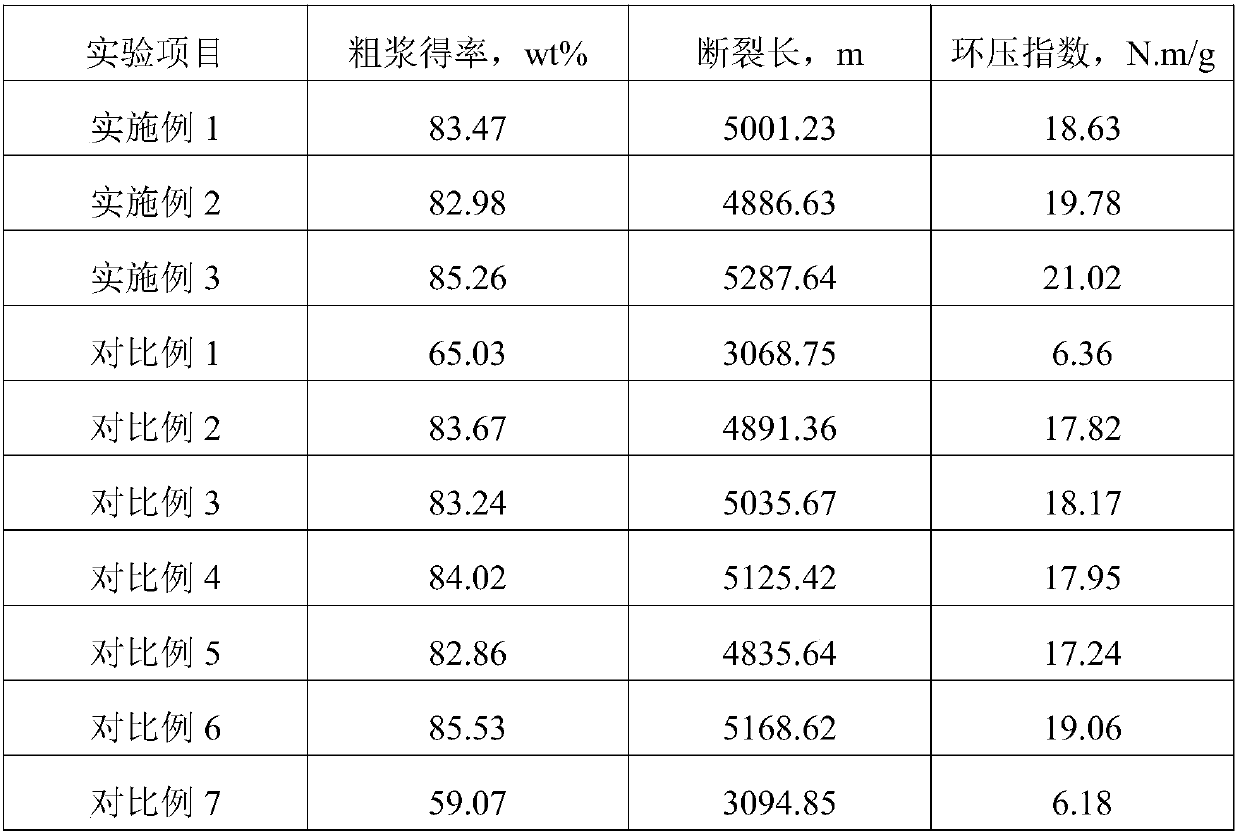

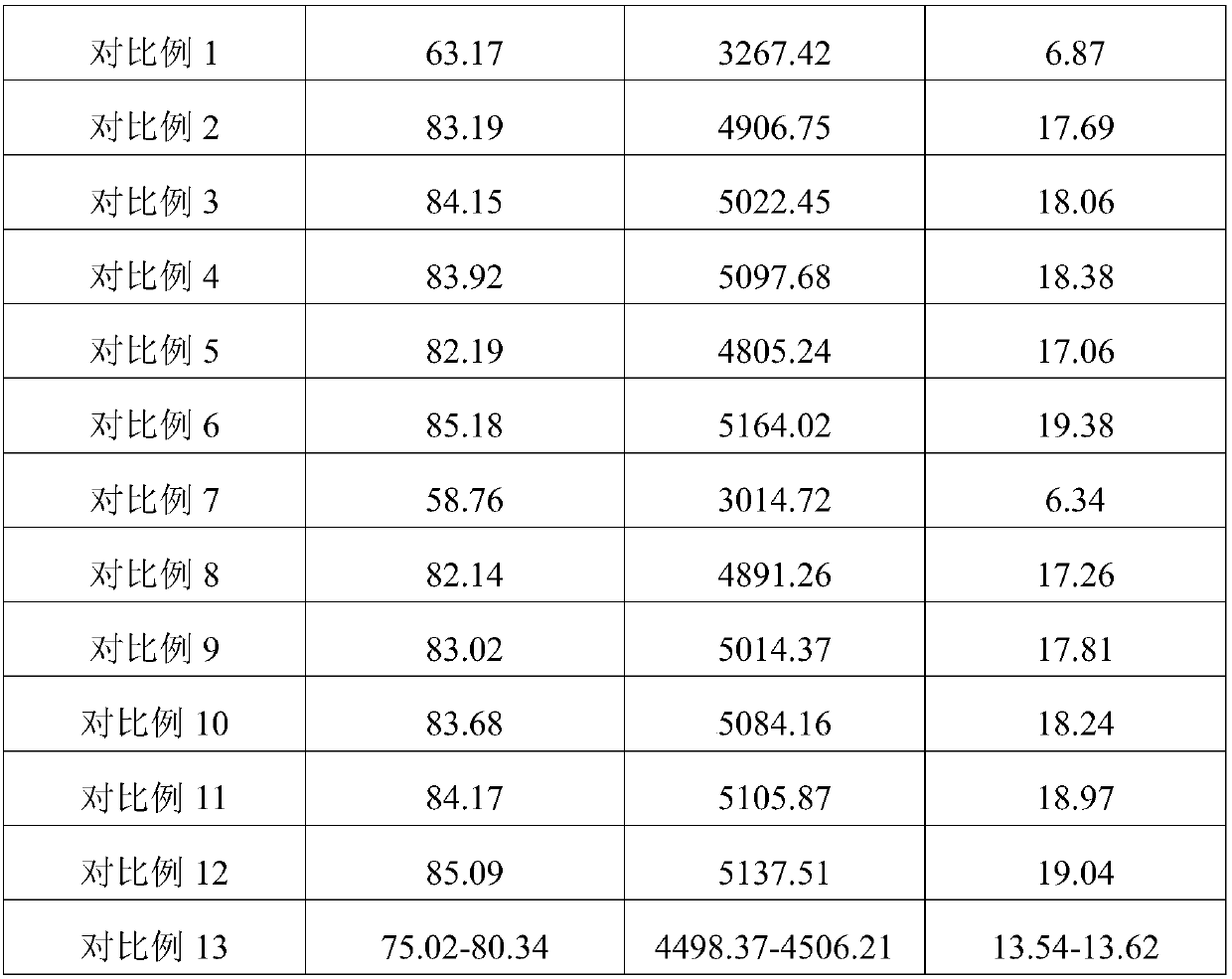

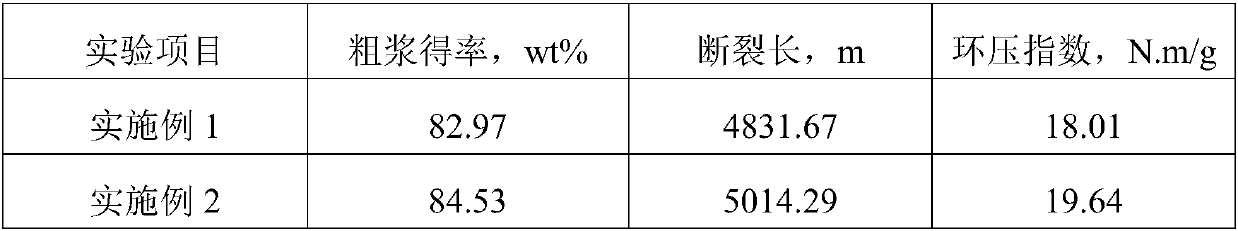

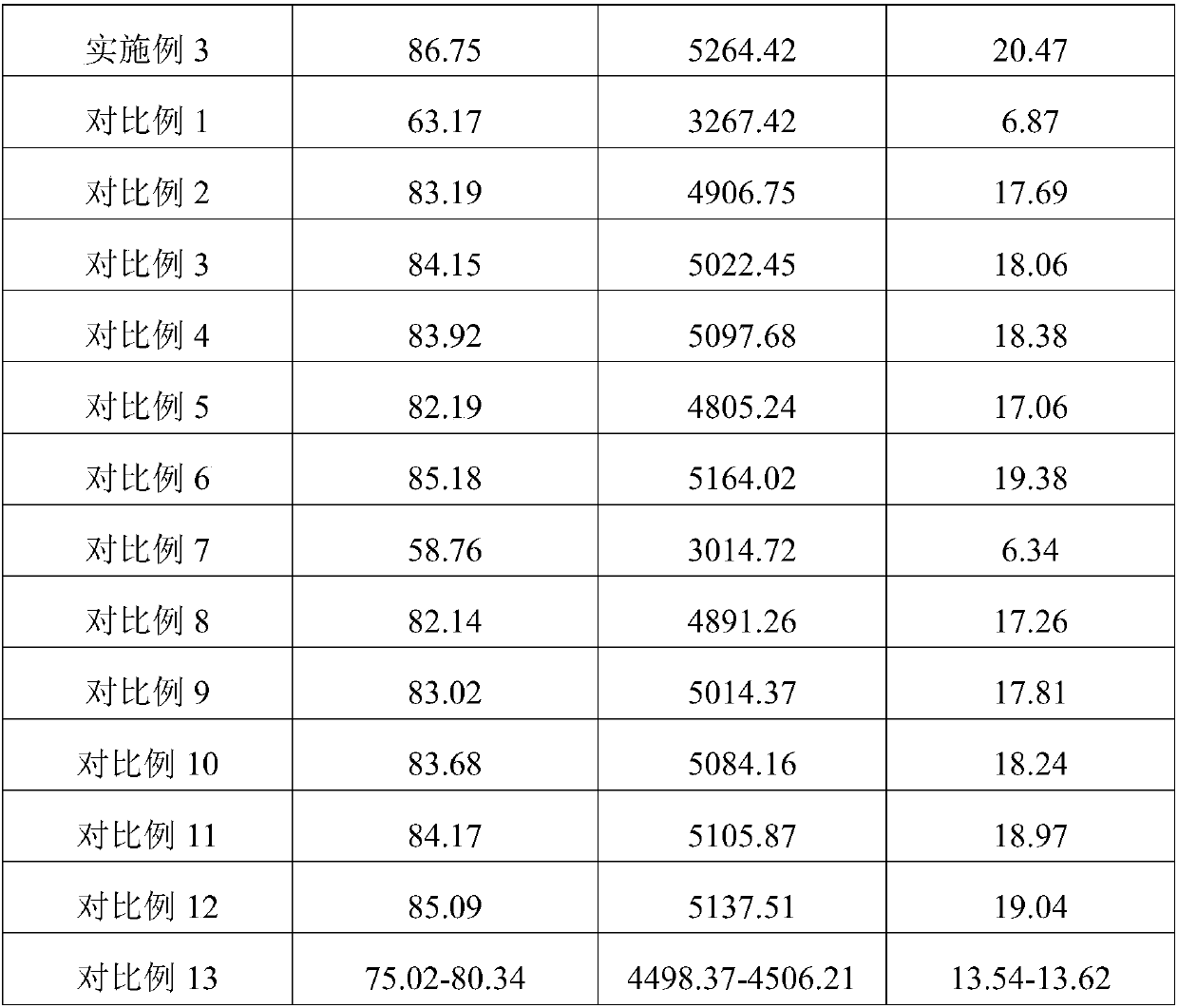

The invention discloses a preparation method of a high-strength corrugated board and belongs to the technical field of papermaking; the high-strength corrugated board is made via the steps of secondary pretreating, grinding, beating, forming and the like. The yield, breaking length and ring crush index of crude pulp made by using the preparation method of crude pulp and high-strength corrugated boards are all significantly higher than those of the pulp made by using the prior art; the preparation method meets the national industrial policies of resource conservation, environmental friendliness, circular economy, and energy conservation and emission reduction, the redundant abandoned resources such as bagasse are developed and utilized, contamination can be decreased, and economic benefit can be increased.

Owner:广西金荣纸业有限公司

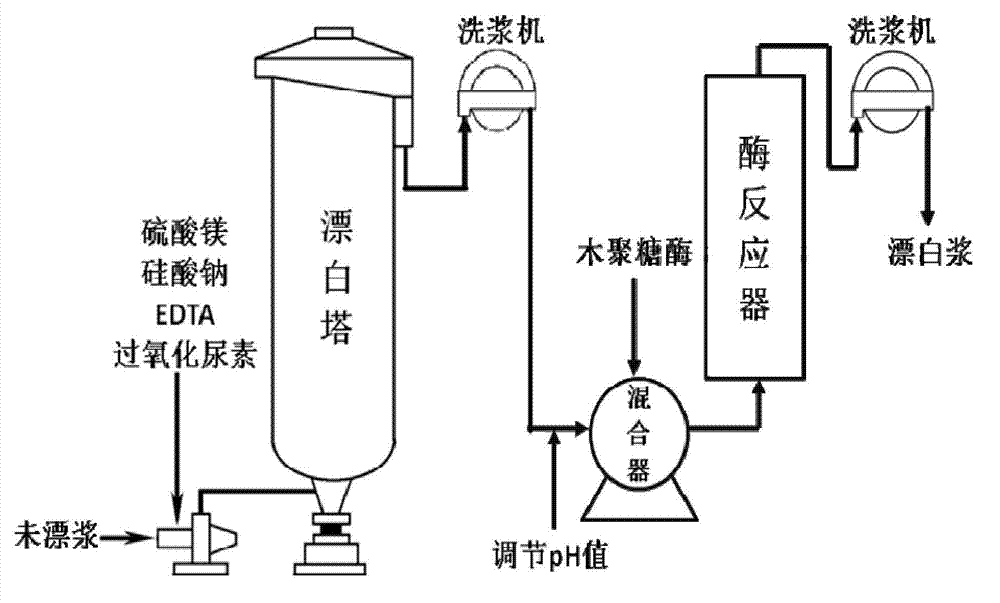

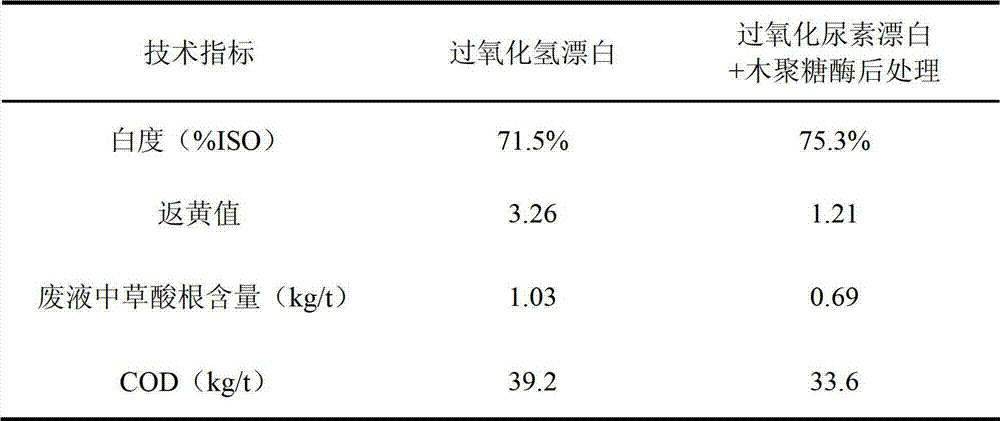

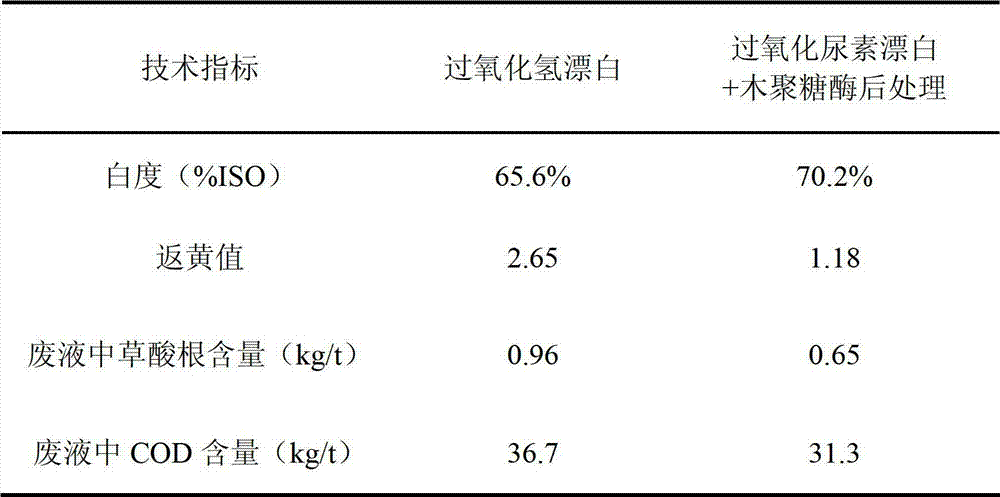

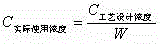

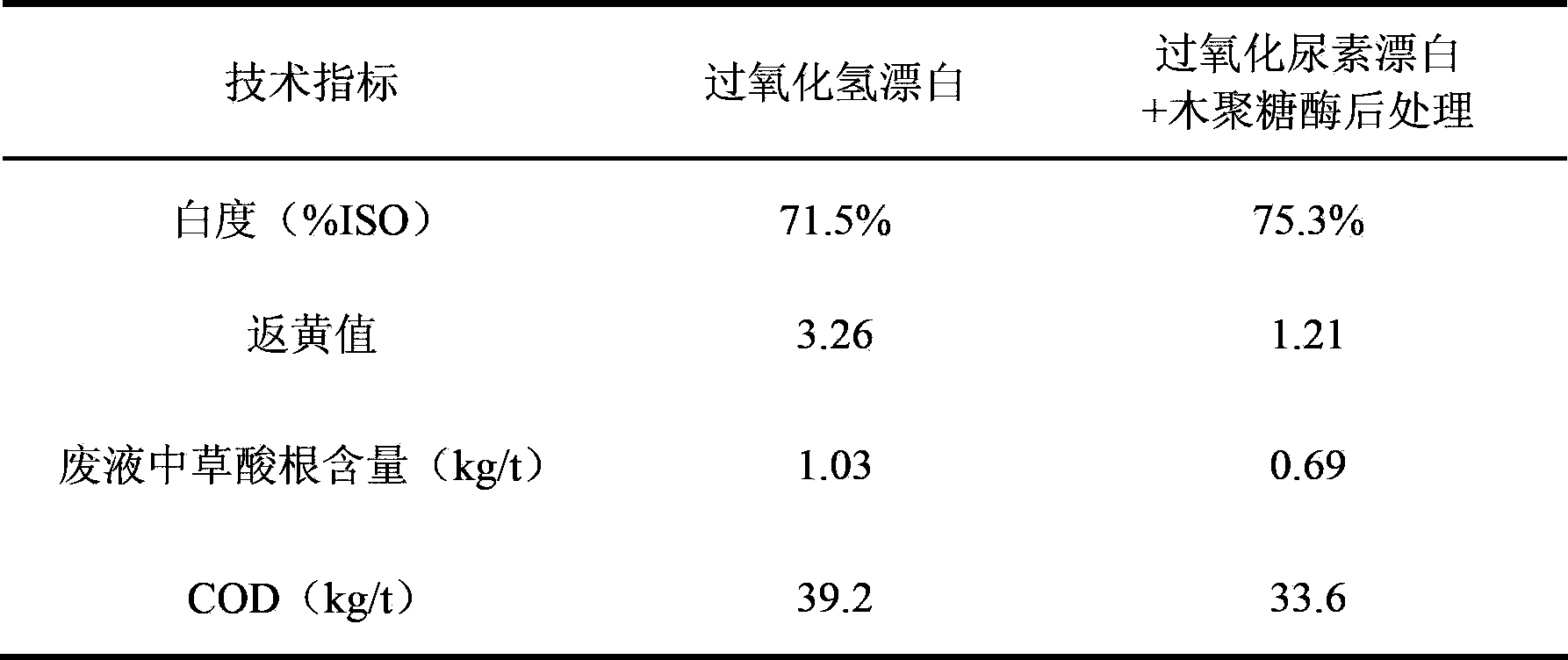

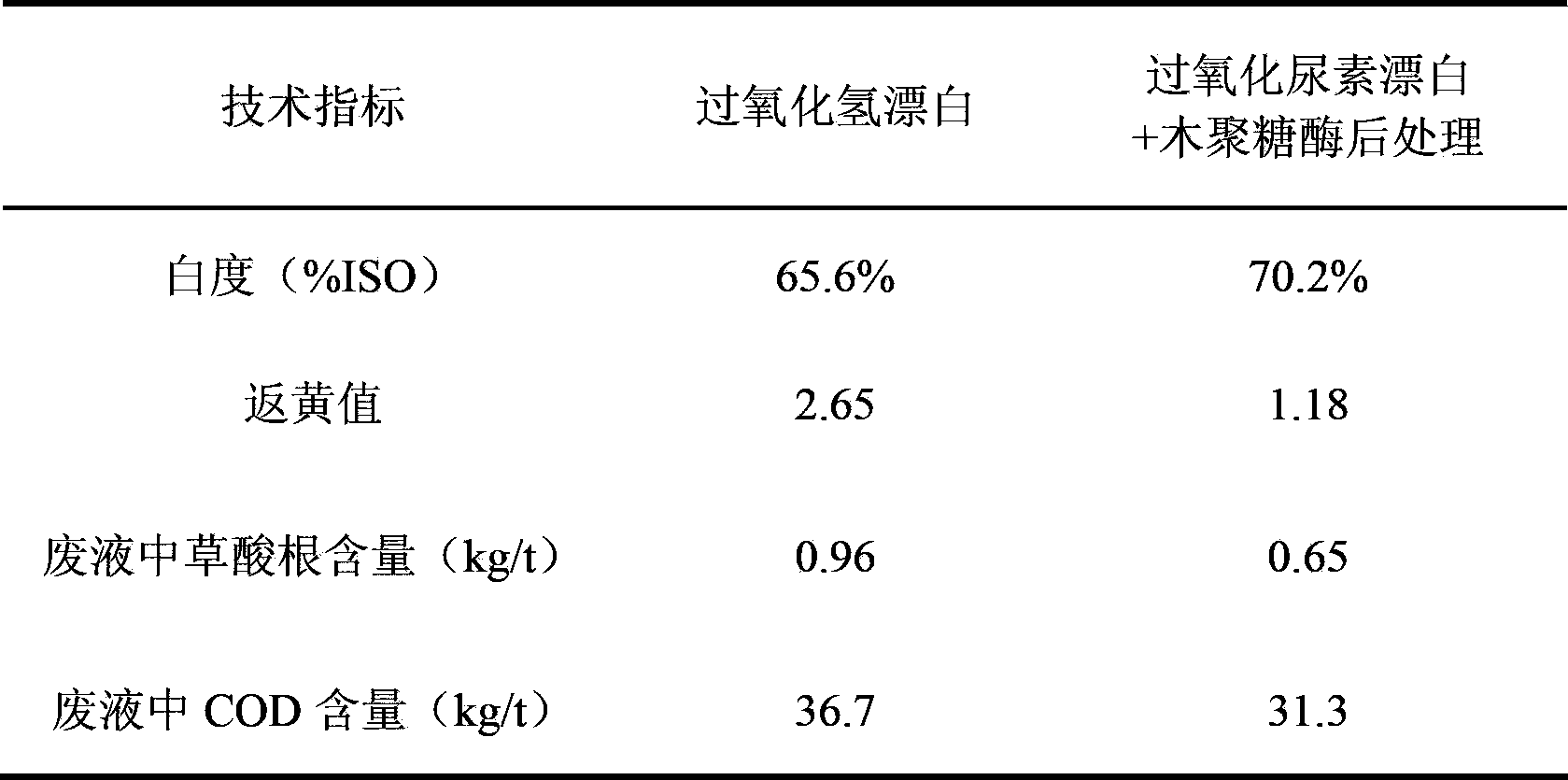

Method for cleanly bleaching chemimechanical pulp

The invention discloses a method for cleanly bleaching chemimechanical pulp. The method comprises the following steps of: firstly, bleaching with carbamide peroxide: adding magnesium sulfate, sodium silicate, EDTA (Ethylene Diamine Tetraacetic Acid) and carbamide peroxide in chemimechanical pulp, adjusting the concentration of paper pulp to 10-15 percent, feeding the paper pulp into a bleaching tower for bleaching and washing after the reaction is ended; and secondly, treating with xylanase: adjusting the pH value of the washed paper pulp to 6.0-7.0, then adding the xylanase, controlling the concentration of paper pulp to 8-12 percent, uniformly mixing, carrying out enzyme treatment and then washing. The carbamide peroxide adopted by the method disclosed by the invention is a novel paper pump bleaching agent and has the advantages of convenience in package and transportation, favorable stability, no addition of alkaline for bleaching, high whiteness of the bleached paper pulp and the like. When the method disclosed by the invention is used for cleanly bleaching the chemimechanical pulp, the whiteness and the whiteness stability of the paper pulp can be improved; meanwhile, the formation of oxalate in the bleaching process is reduced; and the pollution load of wastewater generated by bleaching is reduced.

Owner:SOUTH CHINA UNIV OF TECH

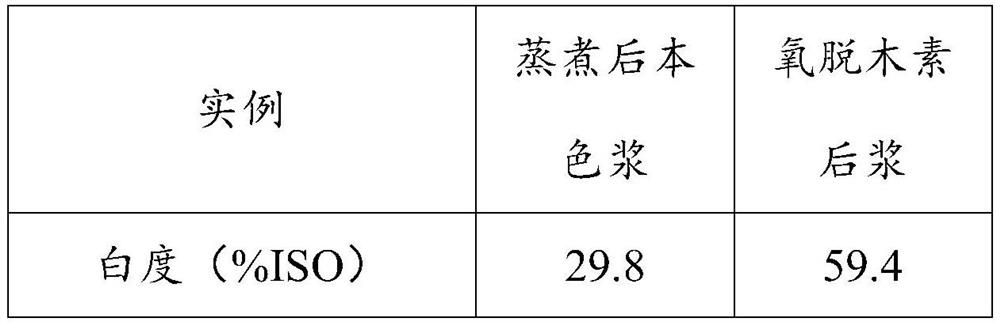

Oxygen delignification process for bamboo wood dissolving pulp

ActiveCN102154885AHigh removal rateLow lignin contentCellulosic pulp after-treatmentDissolving pulpOxygen

The invention belongs to the technical field of preparation of dissolving pulp, and particularly relates to an oxygen delignification process for bamboo wood dissolving pulp. In the process, two sections of oxygen delignification are adopted, and the process comprises the following steps of: A, adding caustic soda in an amount which is 2.0 to 3.0 percent based on the weight of air dry pulp and 1 to 3 kg / admt magnesium sulfate into concentrated pulp, heating to the temperature of 90 to 95 DEG C, feeding into a first-section medium consistency mixer, adding oxygen, mixing, allowing the pulp to enter an up / down flow reaction pipe, and remaining the pulp in the up / down flow reaction pipe for 5 to 10 minutes; and B, heating the pulp flowing from a first-section down flow tower to the temperature of 95 to 102 DEG C, feeding into a second-section medium consistency mixer, adding oxygen, mixing uniformly, feeding into an up flow tower, remaining for 60 to 80 minutes, and after the pressure of the top of the up flow tower reaches 300 to 600 kPa, and spraying to an oxygen delignification spraying groove. After two sections of oxygen delignification, the lignin content of the pulp is lower, and the using amount of chemicals required by subsequent bleaching is reduced further.

Owner:CHONGQING LEE & MAN PAPER MFG

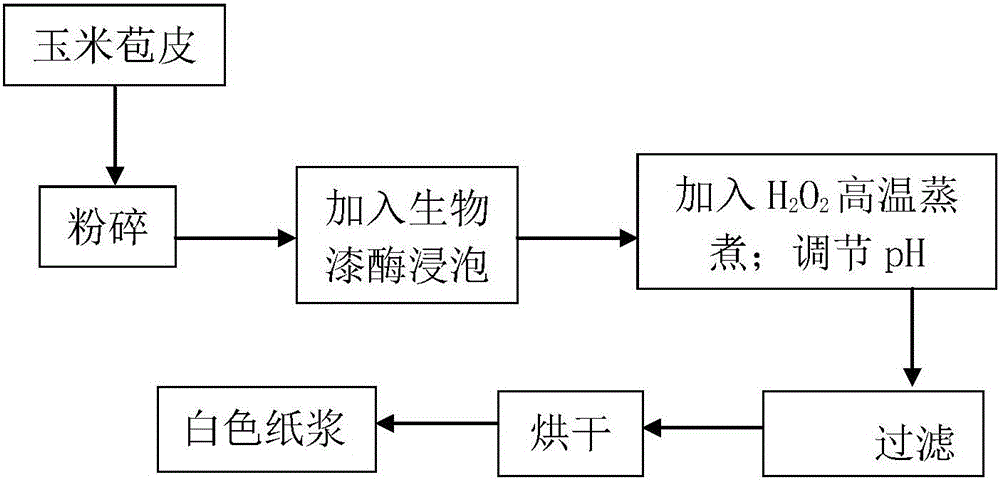

Method for making paper pulp from corn husks with one-pot method

ActiveCN106120432AReduce Bleaching CostsReduce pollutionPulp bleachingNon-woody plant/crop pulpBiologyFiber

The invention discloses a method for making paper pulp from corn husks with a one-pot method. The method is characterized in that fresh corn husks are crushed into thin threadlike fibers with the length smaller than 1 cm; the crushed corn husks are put into a reactor and just soaked with a biological laccase solution with concentration of 10-20 g / L, and a mixed solution is kept at the temperature of 50-60 DEG C for 20-24 h; H2O2 accounting for 10%-20% of the total volume of materials in the reactor, MgSO4 accounting for 0.3%-0.5% of the total mass of the materials in the reactor and 3.0%-5.0% of Na2SiO3 are added, pH is regulated to 9-10, and under the condition that the pH of a system is not changed, the materials are cooked and bleached at the temperature of 90-100 DEG C until the corn husks become white floccular pulp; after cooling, a product is filtered, washed and dried, and the white corn husk paper pulp is obtained. According to the method, cooking and bleaching are performed simultaneously with the one-pot method, the technology is simple, no intermediate pollution products are produced, furthermore, an early-stage preparation process only requires a step of crushing, no wastewater is produced, and accordingly, the whole technology is low in cost and environment-friendly.

Owner:JIANGHAN UNIVERSITY

Papermaking process for improving durability and waterproof properties of paper

InactiveCN108797195AInhibition of catalytic decompositionHigh whitenessNon-macromolecular organic additionVegetable material additionFiberPapermaking

The invention relates to the technical field of papermaking, in particular to a papermaking process for improving the durability and the waterproof properties of paper. The papermaking process includes adding components A after plant fiber raw material pulping steps and before bleaching steps; adding components B before gluing steps in preparation procedures. The components A comprise diethylene triaminepentaacetic acid, sodium dodecyl sulfate and modified chitosan. The components B comprise plant poly-gum, pyrethrin, additive plant extract and modified dialdehyde starch. The papermaking process has the advantages that influence of metal ions on paper pulp bleaching can be effectively reduced, fibers can be effectively swollen up, and the paper is easy to dry; grain phenomena can be reduced, the strength of the paper can be enhanced, the hydration liquid permeation resistance of paper sheets can be improved, and excellent antibacterial and insect prevention effects further can be realized; various added components are nontoxic and harmless, and accordingly the papermaking process is safe and environmentally friendly and has a high practical value and an excellent application prospect.

Owner:泾县狸宣文化用品有限公司

Alkaline bleach liquor extraction process of bamboo wood dissolving pulp

The invention belongs to the technical field of the preparation of dissolving pulp, in particular to an alkaline bleach liquor extraction process of bamboo wood dissolving pulp, which comprises the following steps: A. washing and concentrating pulp bleached by chlorine dioxide, adding 1.2-1.8% of caustic soda, and adjusting the pH value of the pulp to be 10.5-11.0; B. after adjusting the pH value, feeding the pulp into a medium-concentrated stand tube, and adding 3-5kg / admt hydrogen peroxide; C. sending the pulp from the medium-concentrated stand tube into a medium-concentrated mixing device, and adding 3-5kg / admt of oxygen; D. sending the pulp from the medium-concentrated mixing device into an upflow tower, and then overflowing into a downflow tower, and the retention time of the pulp in the upflow tower and the downflow tower is for 75-100min, and the temperature is 80-85 DEG C; and E, pumping the pulp from the downflow tower to a pulp washing machine to wash and concentrate for standby. The alkaline bleach liquor extraction process disclosed by the invention has the advantages that the removal rate of residual lignin is high, the whiteness of the produced pulp is stable, the consumption of chemicals at a subsequent chlorine dioxide bleaching stage can be reduced, and the alpha-cellulose content in the pulp is improved.

Owner:CHONGQING LEE & MAN PAPER MFG

Bleaching agent for polyesteramide and spandex blended fabrics and bleaching method thereof

Owner:SINOPEC YIZHENG CHEM FIBER +1

High-quality antibacterial insect prevention paper manufacturing technology

InactiveCN108867177AInhibition of catalytic decompositionHigh whitenessWater-repelling agents additionVegetable material additionFiberManufacturing technology

The invention relates to the technical field of papermaking and specifically relates to a high-quality antibacterial insect prevention paper manufacturing technology. The manufacturing technology comprises the steps: adding an ingredient A which is prepared from diethylene triaminepentaacetic acid, sodium dodecyl sulfate and modified chitosan after a plant fiber raw material pulping step and before a bleaching step and adding an ingredient B which is prepared from plant multi-glue, pyrethrin, hyperplastic plant extract and modified dialdehyde starch in a preparation process before a gluing step. The manufacturing technology disclosed by the invention can effectively reduce effects of metal ions to paper pulp bleaching, so that fiber can be better swelled, and paper can be dried more easily; in addition, the silk flow phenomenon is reduced, and paper strength is improved; meanwhile, seepage resistance of paper to hydration liquid is improved, and a good antibacterial insect prevention effect is achieved; all the added ingredients have no toxin and harm, so that safety and environmental friendliness are achieved; thus, the manufacturing technology has higher practical value and a good application prospect.

Owner:泾县汇鼎锋建筑装饰工程有限公司

High-strength corrugated paper produced by using bleaching technology

InactiveCN107604760ASave resourcesReduce pollutionSpecial paperPaper/cardboardFiltrationEconomic benefits

The invention discloses high-strength corrugated paper produced by using a bleaching technology and belongs to the technical field of paper making. The high-strength corrugated paper is prepared by the steps of secondary pretreatment, washing, pulping, bleaching, pressure filtration, beating, forming and the like. Unscreened yield, breaking length and a ring crush index of a process for preparingsugarcane bleaching pulp and the high-strength corrugated paper are remarkably higher than those of the prior art; the process accords with an industrial policy of resource conservation and circular economy in China; abundant and wasted material resources, such as bagasse, are developed and utilized, so that pollution is reduced, and economic benefits are increased.

Owner:广西金荣纸业有限公司

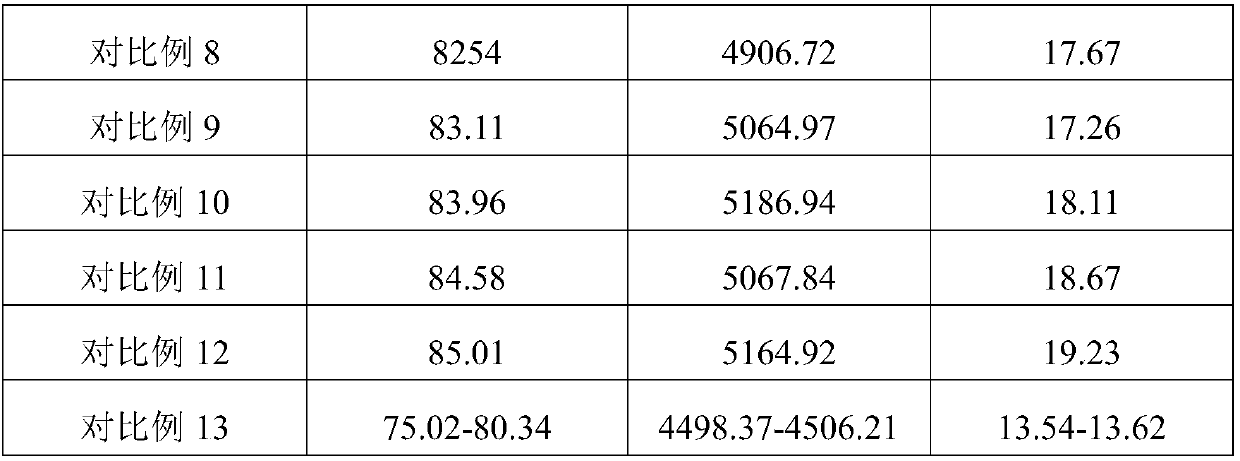

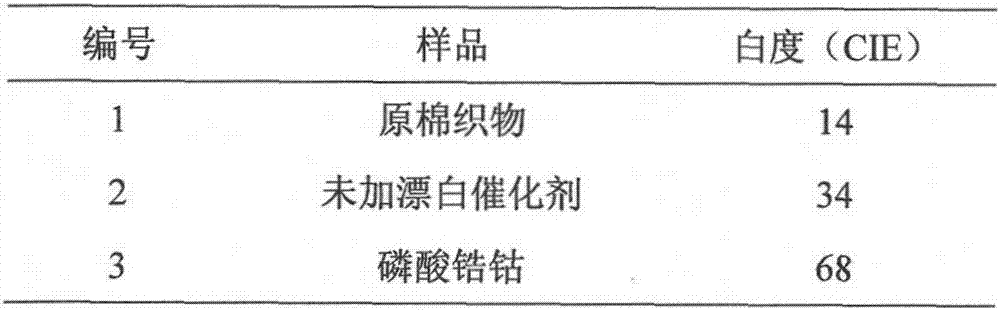

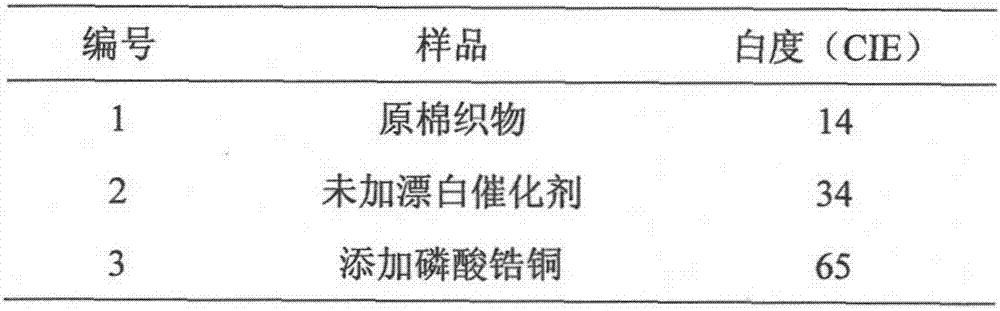

Pretreatment process for cotton fabric bleaching

InactiveCN107022894AModerate bleaching rateImprove bleaching efficiencyTextiles and paperFiberSolubility

The invention provides a pretreatment process for cotton fabric bleaching. The pretreatment process for the cotton fabric bleaching is characterized in comprising the following steps: preparing a solution containing bleach catalysts and hydrogen peroxide, putting unbleached cotton or cotton-containing fabrics into the solution containing the bleach catalysts and hydrogen peroxide according to a certain bath ratio, bleaching the fabrics for a certain time under a certain temperature, taking out the fabrics, washing the fabrics and drying the fabrics; the bleach catalysts are at least one of non-water-soluble zirconium phosphate double salts with a general structural formula of MZr (PO4) 2, wherein M is Co<2+>, Ni<2+> and Cu<2+>. The pretreatment process for the cotton fabric bleaching is good in bleaching effects, no need for strong alkali conditions, and cannot cause serious damage to fabric fibers. The zirconium phosphate double salt is low in water solubility, non-toxic and harmless to the environment, easy to separate, conducive to green production, and good in application prospects.

Owner:DONGHUA UNIV

Preparation method of unbleached pulp for high-strength corrugated paper

InactiveCN107675546APlay a role in penetrationAct as surface activeNon-fibrous pulp additionPaper/cardboardFiltrationPapermaking

The invention discloses a preparation method of an unbleached pulp for high-strength corrugated paper, and belongs to the technical field of papermaking. The high-strength corrugated paper is preparedby the steps of secondary pretreatment, pulp grinding, pressure filtration and the like. The coarse pulp yield of the unbleached pulp prepared with the method provided by the invention is obviously higher than that of the coarse pulp prepared in the prior art; and the process is in line with the industrial policy of national resource saving, environmental protection, circular economy, energy saving and emission reduction. Bagasse and other rich and abandoned material resources are developed and utilized, and the economic efficiency is improved.

Owner:广西金荣纸业有限公司

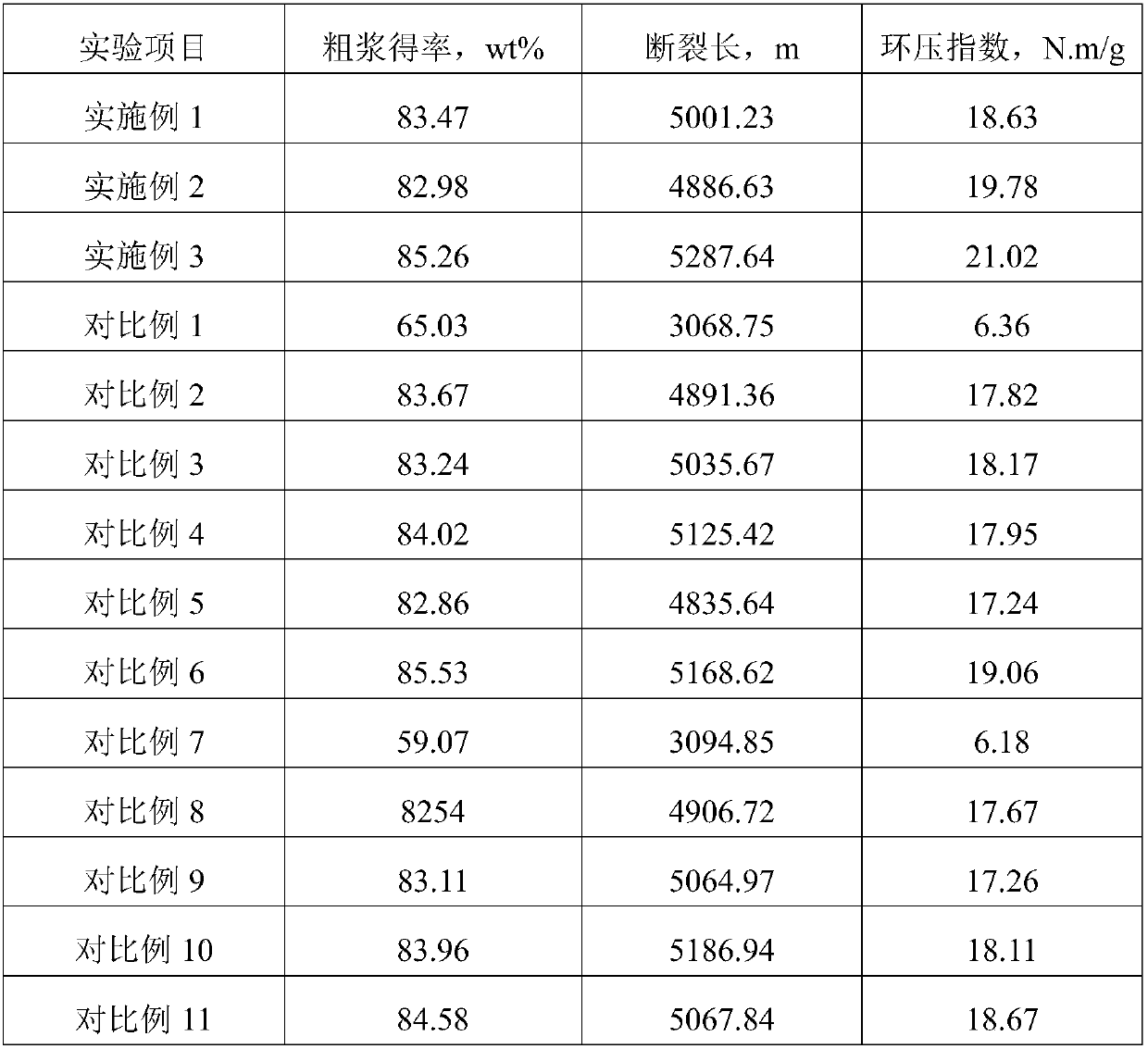

Pretreatment method for producing bleach pulp for high-strength corrugated paper

InactiveCN107604729ASave resourcesReduce pollutionRaw material pretreatmentPretreatment methodBleach

The invention discloses a pretreatment method for producing bleach pulp for high-strength corrugated paper. The pretreatment method comprises the following steps of S1, crushing bagasse, conveying anobtained crushed substance into primary treating liquid, soaking for 20min to 30min when ultrasonic power is 80W to 120W and temperature is 40 to 50 DEG C, and next, filtering, so as to obtain a soaked material a; S2, conveying the soaked material a prepared in the step S1 into secondary treating liquid, cooking under heating, and next, filtering, so as to obtain a soaked material b, thereby completing the pretreatment procedure of preparing the bleach pulp. A coarse-pulp yield, a breaking length and a ring crush index which are obtained by the process, for preparing sugarcane bleach pulp andthe high-strength corrugated paper, of the pretreatment method are all obviously higher than the coarse-pulp yield, the breaking length and the ring crush index obtained in the prior art.

Owner:广西金荣纸业有限公司

Preparation method for bamboo wood dissolving pulp

InactiveCN102352572BHigh strengthIncrease productionCellulose material pulpingDissolving pulpIndustrial engineering

The invention belongs to the technical field of bamboo wood dissolving pulp, and particularly relates to a preparation method for the bamboo wood dissolving pulp, which comprises the following preparation steps: (a) preparing a material; (b) cooking; (c) screening; (d) washing; (e) bleaching; and (f) manufacturing paper with the pulp. By adopting the preparation method for the bamboo wood dissolving pulp, the production efficiency and the product quality can be improved, simultaneously, the energy consumption, the chemical consumption and the pollution load are reduced, and the prepared bamboo wood dissolving pulp has high quality and high quality.

Owner:CHONGQING LEE & MAN PAPER MFG

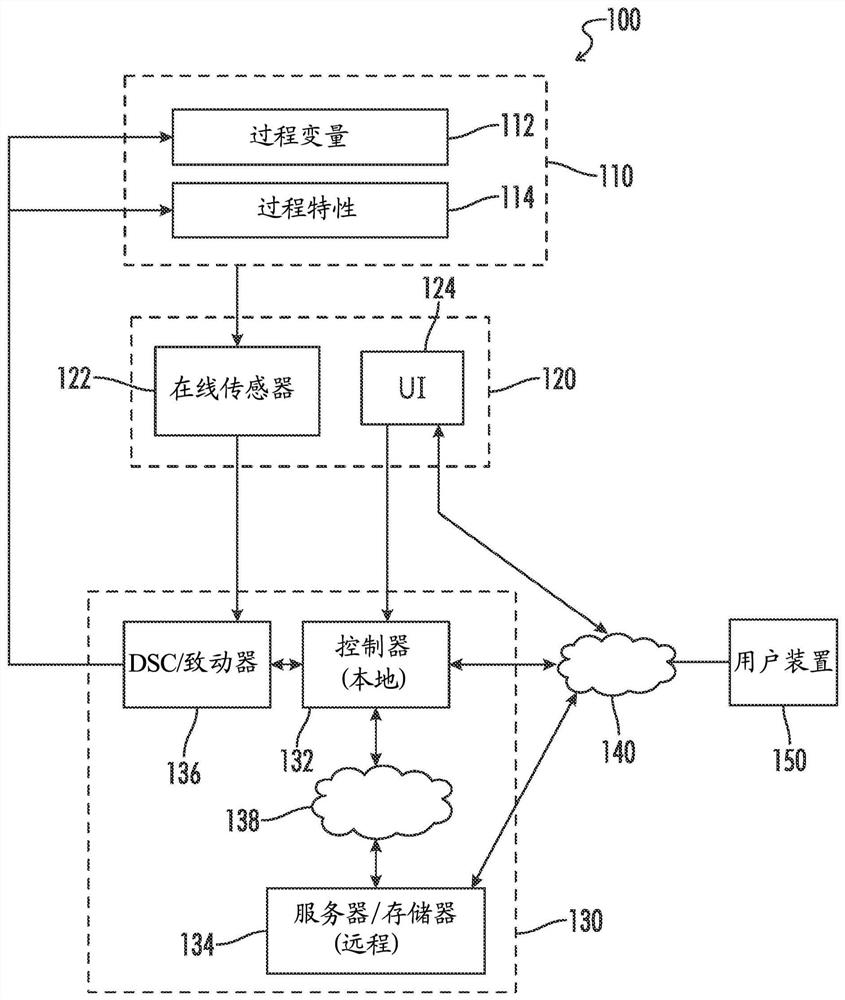

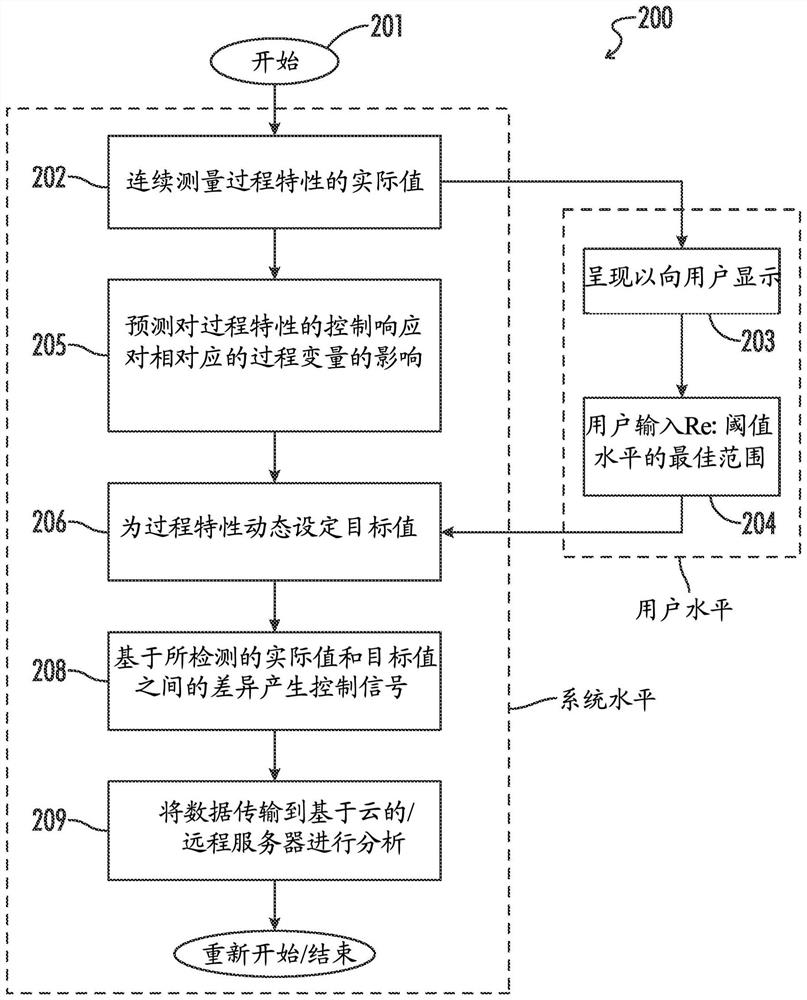

Predictive control system and method for card pump washing process in a pump plant

PendingCN114829705AIncrease productionImprove qualityWashing/displacing pulp-treating liquorsDigestersLine sensorControl signal

Systems and methods for predictive control of coarse pulp processing at a pulp mill are provided. Various on-line sensors produce output signals representing actual values of respective process characteristics, each of which is directly or indirectly affected by adjustments to a corresponding process variable. The controller uses the output signal or related measurement data to dynamically set a target value for the process characteristic based on the predicted impact on the control response of the corresponding process variable. The controller further generates control signals to actuators associated with the respective process variables based on differences between the detected respective actual values and target values. Exemplary pulp wash control systems may optimize various types of pulp wash configurations, including, for example, vacuum drum washers, compaction baffle washers, chemical washers, direct displacement washers, and wash presses. Cloud-based analysis and machine learning may also be implemented to improve the control algorithm over time.

Owner:BUCKMAN LAB INT INC

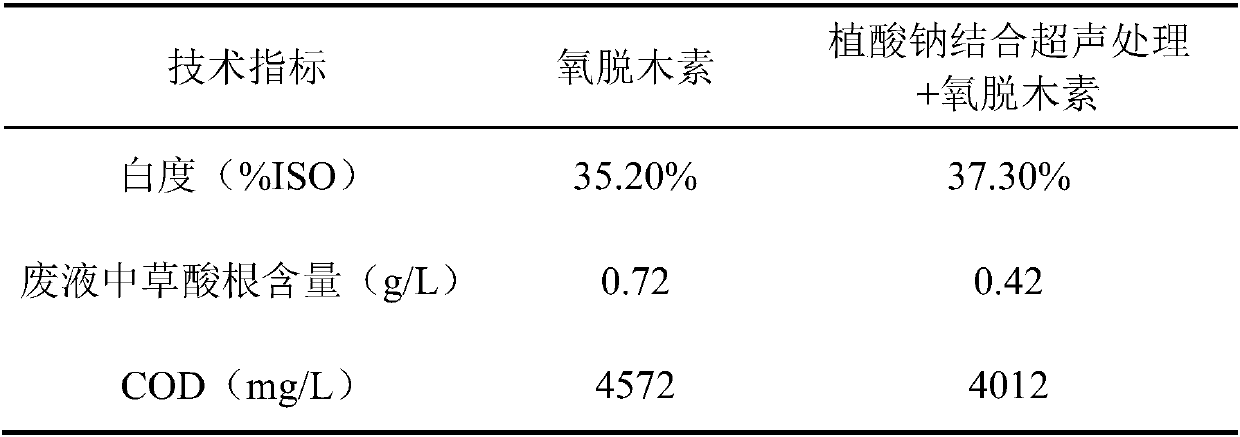

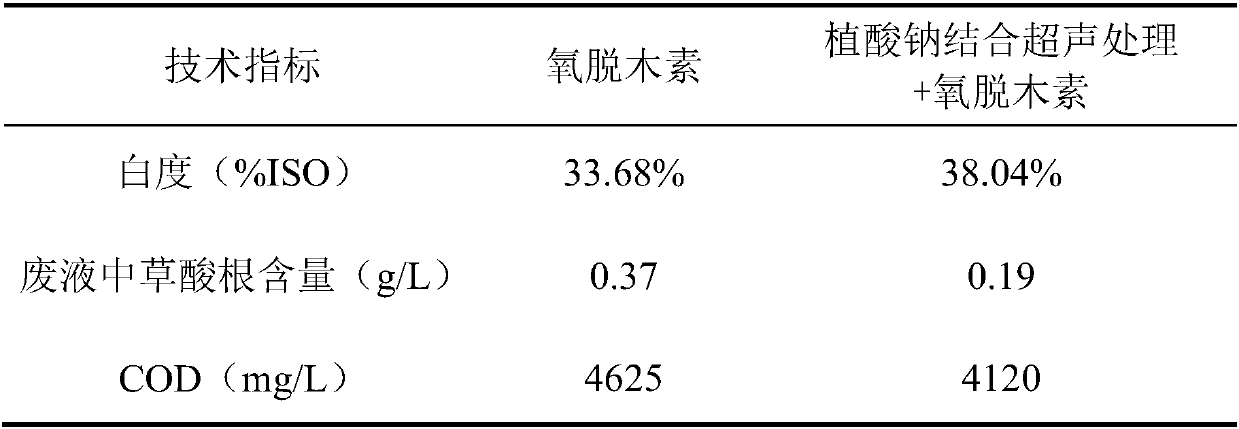

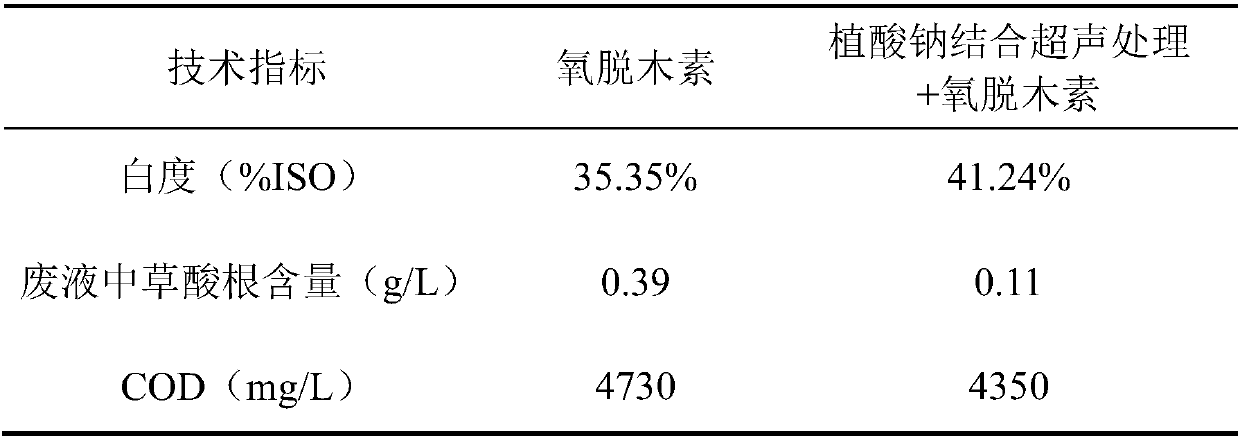

A method of reducing oxalate formation during oxygen delignification

The invention discloses a method for reducing oxalate radicals formed in an oxygen delignification process. The method is characterized by comprising the following steps: (1) ultrasonically processing sodium phytate: adding sodium phytate into paper pulp, controlling pulp concentration at 5%-15%, uniformly mixing and then ultrasonically processing and washing after the ending of processing; (2) oxygen delignification: adding sodium hydroxide and magnesium hydrate into the pulp after being processed, controlling the pulp concentration at 5%-15%, performing oxygen delignification, and then washing. The sodium phytate adopted in the method is an important pure natural green additive, has strong chelation effect with metal ions and has the advantages of economic and environment-friendly effects, simplicity in operation and high pulp whiteness after bleaching. The oxygen delignification for the pulp according to the method can increase the whiteness of the pulp, can reduce the forming of the oxalate radicals in the oxygen delignification process and can reduce the pollution load of the oxygen delignification wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Primary treatment liquid and application thereof in preparing high-strength corrugated paper

InactiveCN107675548APlay a role in penetrationAct as surface activeNon-fibrous pulp additionPaper/cardboardSulfonatePolyethylene glycol

The invention discloses a primary treatment liquid and application thereof in preparing high-strength corrugated paper and belongs to the technical field of paper making. The primary treatment liquidcomprises the following raw materials in parts by weight: 3-6 parts of polyethylene glycol, 4-8 parts of fatty alcohol-polyoxyethylene ether, 1-2 parts of fatty alcohol-polyoxyethylene ether ammoniumsulfate, 2-4 parts of succinic acid alkyl ester sodium sulfonate, 1-0.2 part of cellulase and 50-120 parts of water. The yield, the breaking length and the ring crush index of crude pulp prepared by using a process for preparing original color paper pulp and high-strength corrugated paper are all remarkably prior to those of crude pulp prepared by using the prior art, and the primary treatment liquid meets the national industrial policies of resource conservation, environment protection, circulation economy and energy conservation and emission reduction.

Owner:广西金荣纸业有限公司

Alkaline bleach liquor extraction process of bamboo wood dissolving pulp

Owner:CHONGQING LEE & MAN PAPER MFG

Secondary treatment liquid and application of liquid in production of high-strength corrugated paper

InactiveCN107858845APlay a role in penetrationAct as surface activePulp beating methodsPulping with inorganic basesPapermakingKetone

The invention discloses a secondary treatment liquid and an application of the liquid in production of high-strength corrugated paper, and belongs to the technical field of papermaking. The secondarytreatment liquid comprises the following raw materials in parts by weight: 6-10 parts of 1,3-diketone, 2-4 parts of sodium lauryl sulfate, 8-22 parts of urea hydrogen peroxide, 0.3-0.5 part of magnesium oxide, 4-6 parts of sodium hydroxide, and 60-200 parts of water. The secondary treatment liquid provided by the invention is in line with the China industrial policies of resource conservation, environmental friendliness, circular economy, energy conservation and emission reduction.

Owner:广西金荣纸业有限公司

Preparation process of bleaching pulp for production of high-strength corrugated paper

InactiveCN107675547ASave resourcesReduce pollutionNon-fibrous pulp additionPaper/cardboardPre treatmentPapermaking

The invention discloses a preparation process of bleaching pulp for production of high-strength corrugated paper, and belongs to the technical field of papermaking. The bleaching pulp is prepared by the steps of performing pretreatment for twice, washing, performing defibrination, bleaching, performing filter pressing and the like. The yield of crude pulp of the prepared sugarcane bleaching pulp is obviously higher than the yield of the crude pulp prepared according to the prior art; according to the process, rich and abandoned material resources such as bagasse are utilized, so pollution canbe reduced and the economic benefit can be improved.

Owner:广西金荣纸业有限公司

Paper preparation, modification and optimization method

InactiveCN108755234AInhibition of catalytic decompositionHigh whitenessPaper-making machinesFiberPapermaking

The invention relates to the technical field of papermaking, in particular to a paper preparation, modification and optimization method. The method includes: adding a component A composed of diethylene triaminepentaacetic acid, sodium dodecyl sulfate and modified chitosan after plant fiber raw material pulping and after bleaching; adding a component B composed of plant multi-glue, pyrethrin, modification plant extract and modified dialdehyde starch before glue applying in the process of preparation. By the method, impact of metal ions on paper pulp bleaching can be lowered effectively, good swelling of fiber can be realized, and paper is easier to dry; filament phenomena can be reduced, strength of the paper is improved, permeation resistance of paper sheets to hydration liquid is improved, and the paper has good bacteriostatic and insect-resistant effect; the added components are nontoxic, harmless, safe and environment, so that the method has high practical value and good applicationprospect.

Owner:泾县瑞旺农业科技服务有限公司

A kind of bleaching process of raffia

The invention relates to a raffia bleaching process, which belongs to the technical field of raffia bleaching. The raffia bleaching process comprises the steps of preprocessing, oxygen bleaching, primary water washing, reduction bleaching and secondary water washing. In the oxygen bleaching step, raffia is bleached for 60 min in a bleaching solution containing 2 to 2.5g / L of sodium silicate, 3 to 6g / L of hydrogen peroxide with purity of 100 percent, 2 to 3g / L of hydrogen peroxide stabilizer and 2 to 3g / L of decomposition promoter in a bath ratio of 1 to (80-100) at the temperature of 95 to 100 DEG C; in the reduction bleaching step, the raffia is reduced and bleached for 15 to 30min in a reduction bleaching solution containing 3 to 4g / L of thiourea dioxide in a bath ratio of 1 to (80-100) at the temperature of 80 to 95DEG. By adopting the raffia bleaching process, the raffia can be effectively bleached, the strength loss of the raffia is relatively low in the bleaching process, no pungent smell is produced in the production process, and the COD (chemical oxygen demand) and BOD (biochemical oxygen demand) values during sewage discharging are relatively small; the bleached raffia is high in whiteness and strength.

Owner:SHANDONG VOCATIONAL COLLEGE OF LIGHT IND

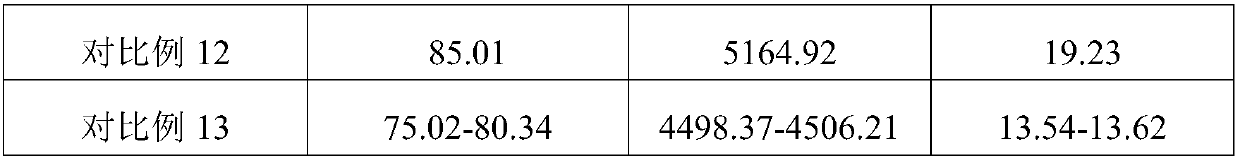

Method for cleanly bleaching chemimechanical pulp

The invention discloses a method for cleanly bleaching chemimechanical pulp. The method comprises the following steps of: firstly, bleaching with carbamide peroxide: adding magnesium sulfate, sodium silicate, EDTA (Ethylene Diamine Tetraacetic Acid) and carbamide peroxide in chemimechanical pulp, adjusting the concentration of paper pulp to 10-15 percent, feeding the paper pulp into a bleaching tower for bleaching and washing after the reaction is ended; and secondly, treating with xylanase: adjusting the pH value of the washed paper pulp to 6.0-7.0, then adding the xylanase, controlling the concentration of paper pulp to 8-12 percent, uniformly mixing, carrying out enzyme treatment and then washing. The carbamide peroxide adopted by the method disclosed by the invention is a novel paper pump bleaching agent and has the advantages of convenience in package and transportation, favorable stability, no addition of alkaline for bleaching, high whiteness of the bleached paper pulp and the like. When the method disclosed by the invention is used for cleanly bleaching the chemimechanical pulp, the whiteness and the whiteness stability of the paper pulp can be improved; meanwhile, the formation of oxalate in the bleaching process is reduced; and the pollution load of wastewater generated by bleaching is reduced.

Owner:SOUTH CHINA UNIV OF TECH

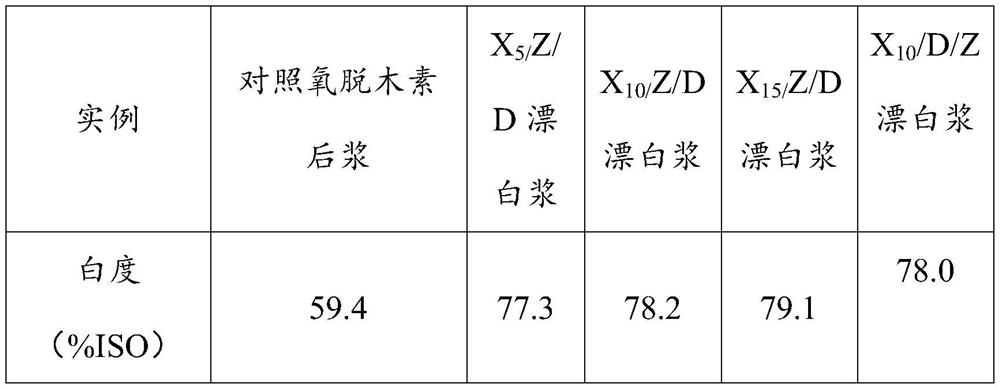

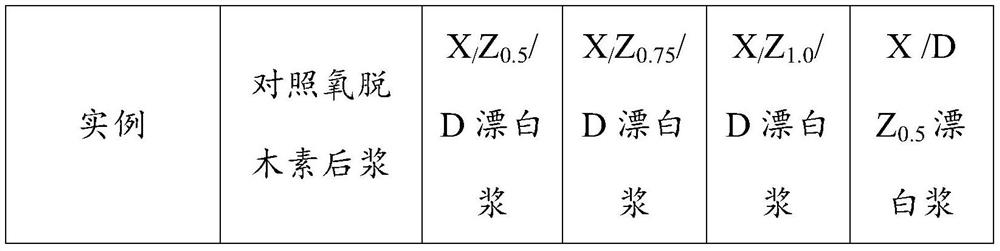

Sequential bleaching process suitable for ECF short-process bleaching

The invention belongs to the technical field of papermaking, and relates to a sequential bleaching process suitable for ECF short-process bleaching. The bleaching process is short, the number of bleaching sections is small, paper pulp among the bleaching sections is not washed with water, and the process is environmentally friendly, economical and effective. The short-process comprises the following steps: firstly, carrying out xylanase-assisted bleaching (X) on unbleached paper pulp, then adjusting the pH value of the paper pulp, adding an auxiliary agent, carrying out ozone bleaching (Z), and carrying out chlorine dioxide bleaching (D) after the ozone bleaching is finished, namely the bleaching process is carried out in an X / Z / D sequence; or after xylanase treatment (X), performing chlorine dioxide bleaching (D) and ozone bleaching (Z) in sequence, namely the bleaching process is carried out in an X / D / Z sequence. According to the sequential bleaching process, the three bleaching agents are not washed, and the whiteness of paper pulp can be improved by 30% ISO or above.

Owner:QILU UNIV OF TECH

Primary treatment solution for producing high strength corrugated paper by utilizing bleaching process and application thereof

InactiveCN107558288APlay a role in penetrationImprove surface activityNon-macromolecular organic additionPaper/cardboardPapermakingMaterial resources

The invention discloses a primary treatment solution for producing high strength corrugated paper by utilizing a bleaching process and application thereof, and belongs to the technical field of papermaking. The primary treatment solution is prepared from the following raw materials in parts by weight: 8-12 parts of octadecanamide, 5-9 parts of fatty alcohol-polyoxyethylene ether, 1.5-2.5 parts ofsodium dodecyl benzene sulfonate, 2.4-4.5 parts of sodium alkyl ester sulfonate succinate, 0.1-0.2 part of cellulase and 70-160 parts of water. The process accords with the industrial policy of national resource conservation and circular economy, and can be used for reducing pollution and improving economic benefit by developing and utilizing rich and waste material resources of bagasse and the like.

Owner:广西金荣纸业有限公司

Low-cost high-quality paper improvement preparation process

InactiveCN108867157AInhibition of catalytic decompositionHigh whitenessWater-repelling agents additionCounter-current extractionFiberDialdehyde starch

The invention relates to the technical field of paper making, in particular to a low-cost high-quality paper improvement preparation process, which comprises the following steps of adding an ingredient A prepared from diethylene triaminepentaacetic acid, sodium dodecyl sulfate and modified chitosan after the plant fiber raw material pulping step and before the bleaching step, and adding an ingredient B prepared from plant poly gum, pyrethrin, additive plant extracts and modified dialdehyde starch before the glue application step in the proportioning process. The process provided by the invention has the advantages that the influence of metal ions on paper pulp bleaching can be effectively reduced, so that the fiber obtains good lubrication swelling effects; paper can be more easily dried;in addition, the generation of thread fluid phenomenon can be reduced; the paper intensity is improved; meanwhile, the anti-seepage power of paper on hydration liquid can be improved; good antibacterial and insect prevention effects can be achieved; each added ingredient is nontoxic and harmless; safety and environment protection are realized; high practicability and good application prospects arerealized.

Owner:合肥晶诺知识产权信息服务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com