Pretreatment process for cotton fabric bleaching

A treatment process and technology for cotton fabrics, applied in the field of cotton fabric bleaching pretreatment process, can solve the problems of high energy consumption, rough hand feel, and fabric strength damage, and achieve low bleaching temperature, controllable temperature and time, and small fiber damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

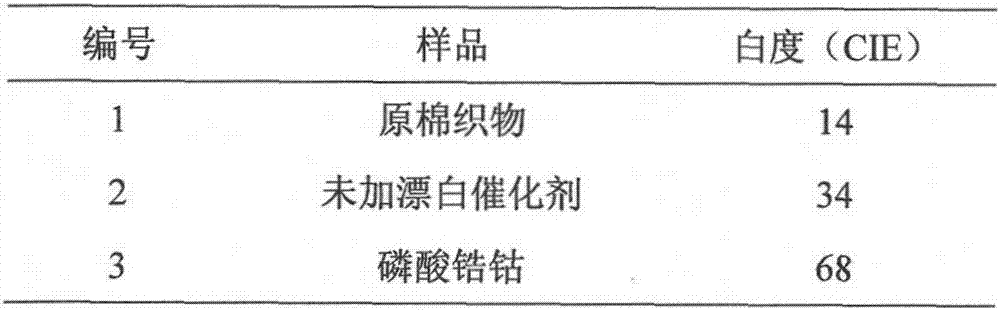

Embodiment 1

[0020] A kind of cotton fabric bleaching pretreatment process, concrete steps are:

[0021] (1) preparation contains the solution of bleaching catalyst and hydrogen peroxide, and bleaching catalyst is zirconium cobalt phosphate, and concentration is 1g / L, H 2 o 2 The content is 8g / L;

[0022] (2) Put the desized cotton fabric into the above-mentioned solution containing bleach catalyst and hydrogen peroxide at a bath ratio of 20:1, bleach at 80° C. for 30 minutes, take out the fabric, then wash and dry it.

[0023]

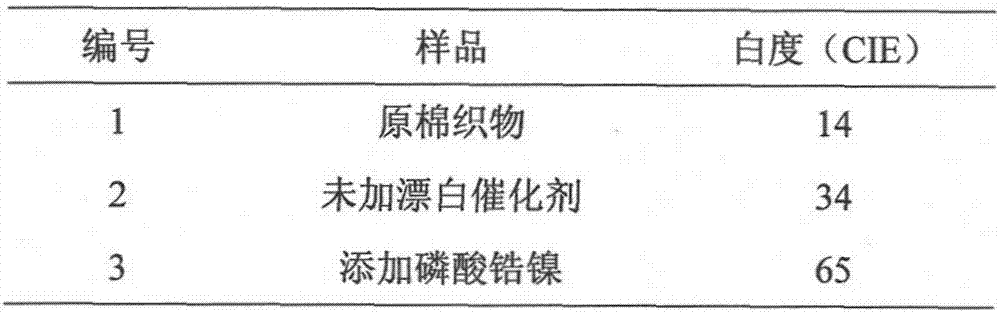

Embodiment 2

[0025] A kind of cotton fabric bleaching pretreatment process, concrete steps are:

[0026] (1) preparation contains the solution of bleaching catalyst and hydrogen peroxide, and bleaching catalyst is zirconium nickel phosphate, and concentration is 3g / L, H 2 o 2 The content is 5g / L;

[0027] (2) Put the desized cotton fabric into the above-mentioned solution containing bleach catalyst and hydrogen peroxide at a liquor ratio of 30:1, bleach at 70° C. for 45 minutes, take out the fabric, then wash and dry it.

[0028]

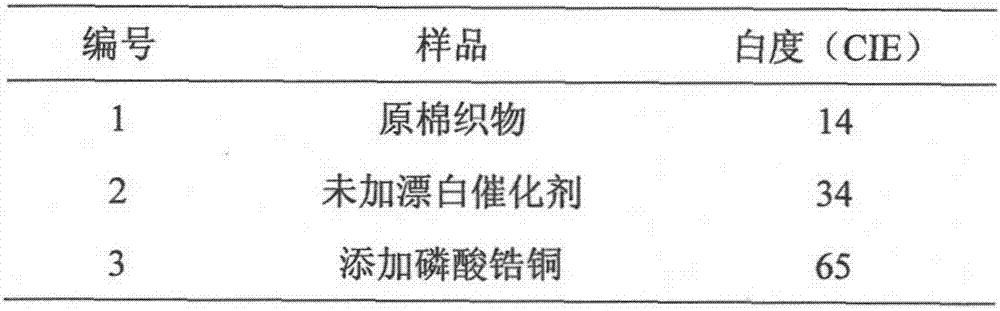

Embodiment 3

[0030] A kind of cotton fabric bleaching pretreatment process, concrete steps are:

[0031] (1) preparation contains the solution of bleaching catalyst and hydrogen peroxide, and bleaching catalyst is zirconium copper phosphate, and concentration is 5g / L, H 2 o 2 The content is 6g / L;

[0032] (2) Put the desized cotton fabric into the above-mentioned solution containing bleach catalyst and hydrogen peroxide at a liquor ratio of 10:1, bleach at 60° C. for 60 minutes, take out the fabric, then wash and dry it.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com