Clean preparation method of carboxymethyl nanocellulose material

A carboxymethyl nano and cellulose technology, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of difficult preparation of ether-ester mixed derivative materials, destruction of nano-cellulose nano-characteristics, and difficulty in controlling the nano-scale of products. Achieve the effect of simple and coherent process technology, speed up mass transfer rate, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

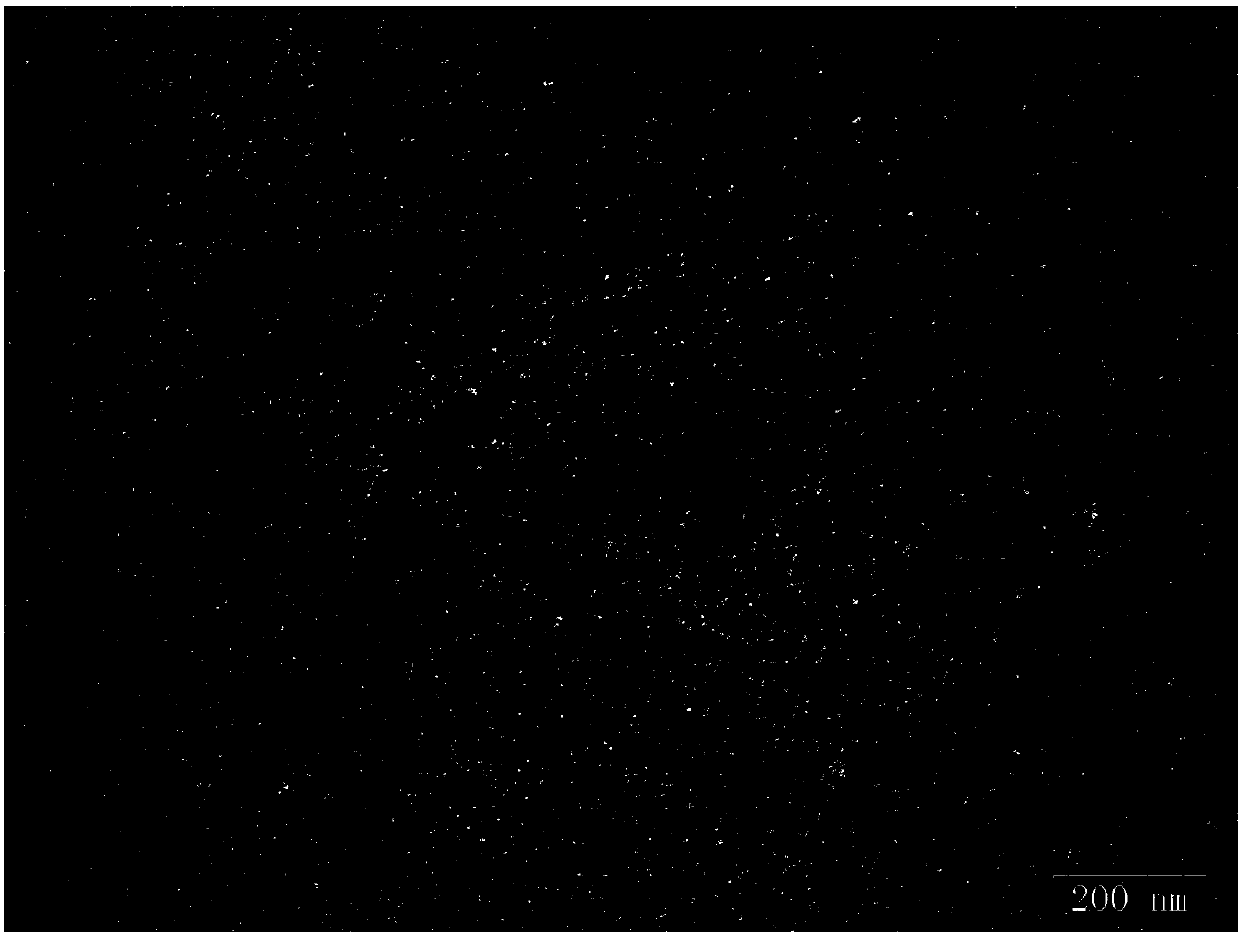

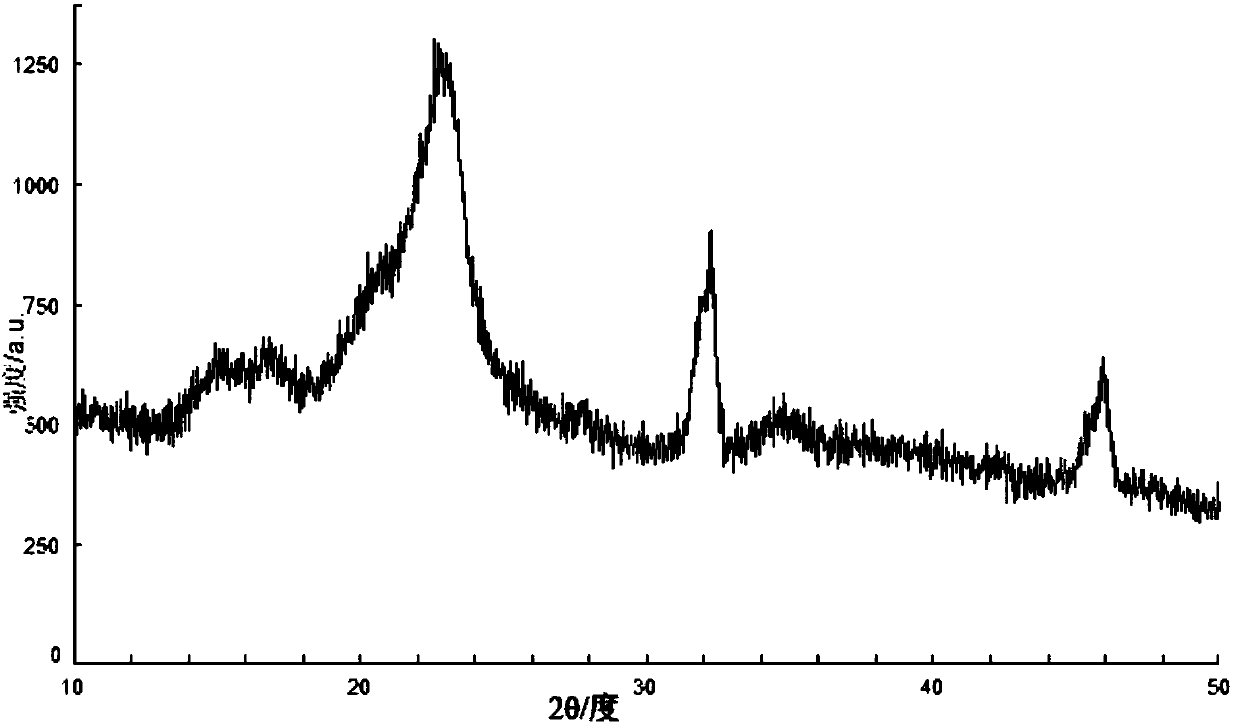

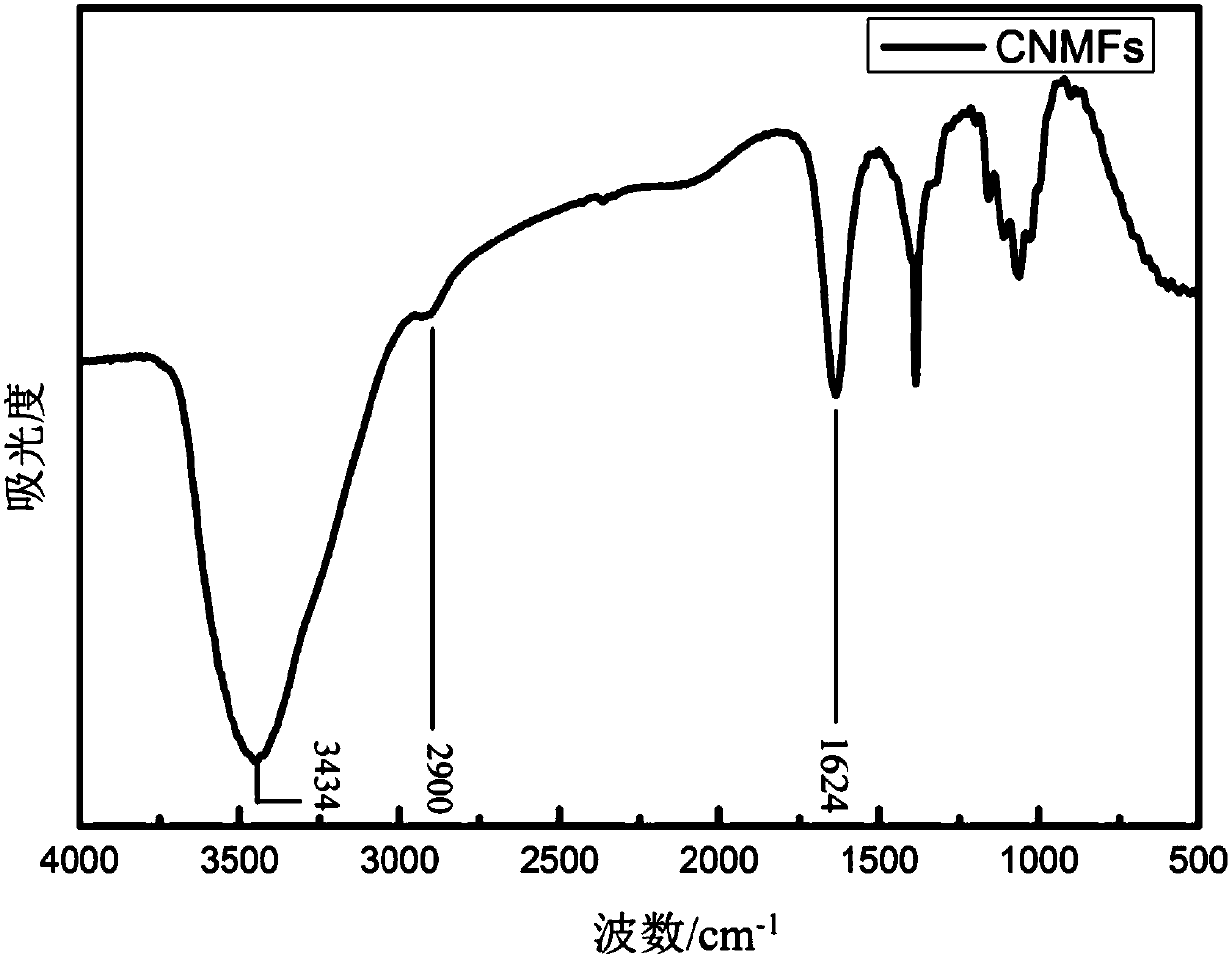

Image

Examples

Embodiment 1

[0038] Add 40 g of wheat straw powder crushed to 60 meshes into an aqueous solution containing 2% sodium hydroxide, 0.4% magnesium sulfate, 2% layer silicon, 0.1% sodium citrate, 0.3% methylene phosphonic acid, and 0.1% penetrant, Presoak at 40°C for 60 minutes, filter and set aside. Transport the pre-soaked wheat straw powder into the mixer, add 2% hydrogen peroxide concentration, 3% sodium hydroxide concentration, Na 2 SiO 3 , MgSO 4 and NaBH 4 Bleach with 2000g of bleaching solution I with a concentration of 2% for 1 hour, filter the bleaching solution and send it to a continuous oxygen bleaching machine, add 300 parts of hydrogen peroxide with a concentration of 27.5%, 1 part of dicyandiamide catalyst, 60 parts of oxygen, and 1 part of phenanthroline The bleaching solution II was bleached for 1 hour, then filtered and dried.

[0039] Under stirring conditions, 12g of sodium hydroxide was added to 600g of isopropanol / water solution with a mass concentration of 85%, and ...

Embodiment 2

[0042] Add 40 g of cotton straw powder crushed to 60 meshes into an aqueous solution containing 2% sodium hydroxide, 0.4% magnesium sulfate, 3% layer silicon, 0.1% sodium citrate, 0.4% methylene phosphonic acid, and 0.1% penetrant, Presoak at 50°C for 50 minutes, filter and set aside. The pre-soaked cotton straw powder is delivered to the mixer, and the concentration of hydrogen peroxide is 3%, the concentration of sodium hydroxide is 4%, Na 2 SiO 3 , MgSO 4 and NaBH 4 Bleach with 2000g of bleaching solution I with a concentration of 2% for 1 hour, filter the bleaching solution and send it to a continuous oxygen bleaching machine, add 300 parts of hydrogen peroxide with a concentration of 27.5%, 1 part of dicyandiamide catalyst, 60 parts of oxygen, and 1 part of phenanthroline The bleaching solution II was bleached for 1 hour, then filtered and dried.

[0043] Under stirring conditions, 15g of sodium hydroxide was added to 600g of isopropanol / water solution with a mass con...

Embodiment 3

[0046] Add 40 g of reed pulp crushed to 50 meshes into an aqueous solution containing 2% sodium hydroxide, 0.4% magnesium sulfate, 2% layer silicon, 0.1% sodium citrate, 0.5% methylene phosphonic acid, and 0.1% penetrant. Presoak at 50°C for 40 minutes, filter and set aside. The pre-soaked cotton stalk powder is delivered to the mixer, and the concentration of hydrogen peroxide is 2%, the concentration of sodium hydroxide is 4%, Na 2 SiO 3 , MgSO 4 and NaBH 4 Bleach with 2000g of bleaching solution I with a concentration of 2% for 1 hour, filter the bleaching solution and send it to a continuous oxygen bleaching machine, add 300 parts of hydrogen peroxide with a concentration of 27.5%, 1 part of dicyandiamide catalyst, 60 parts of oxygen, and 1 part of phenanthroline The bleaching solution II was bleached for 1 hour, then filtered and dried.

[0047] Under stirring conditions, 12g of sodium hydroxide was added to 600g of isopropanol / water solution with a mass concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com