Recombination wood floorboard made by mixing branch wood and bamboo-wood

A technology for recombining wood and branches, which is applied in the direction of floors, buildings, and building structures. It can solve the problems of uneven thickness of branches, uneven density of boards, and poor gluing, so as to alleviate uneven density, less holes, and poor gluing. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

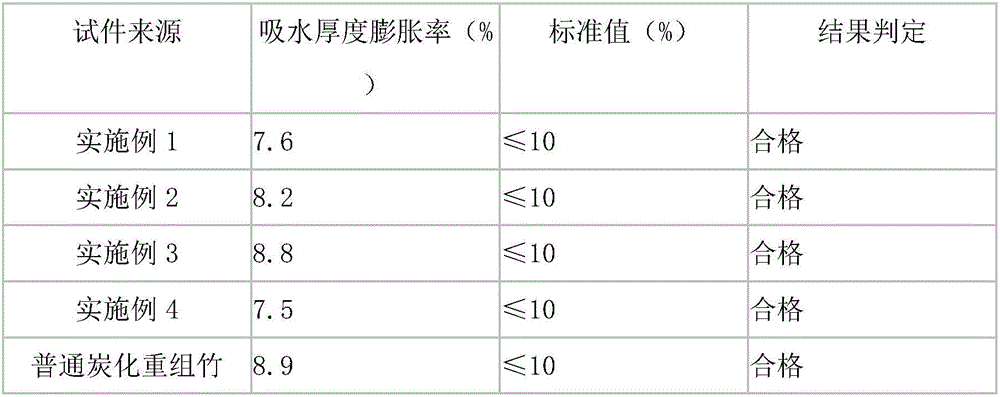

Examples

Embodiment 1

[0020] The production method of the recombined wooden floor mixed with branch wood and bamboo wood, its steps are as follows:

[0021] 1. Prepare raw materials: Cut the branch wood into a fixed length, such as 1.95m, put it into a rolling machine (the rolling machine is specifically a kind of branch wood crushing and crushing device) for crushing and rolling, and flatten the branch wood. , Rotate the fast-growing poplar and camphor wood into 1.5mm-2.0mm, cut into strip-shaped or sheet-shaped units with a width of 5mm-150mm and a length of 1.95m;

[0022] 2. Drying: Dry the rolled branch wood and wood chips obtained by rotary cutting. The drying temperature is 40-60°C, and the moisture content after drying is 10-16%;

[0023] 3. Ultra-high temperature thermal modification: Put the pre-dried poplar wood chips and rolled twigs into the carbonization treatment equipment, raise the temperature to 80°C at a speed of 8°C / min and keep it warm for 2-3 hours, and then heat it at 10°C R...

Embodiment 2

[0028] The production method of the recombined wooden floor mixed with branch wood and bamboo wood, its steps are as follows:

[0029] 1. Prepare raw materials: Cut the branch wood into a fixed length, such as 1.95m, put it into a rolling machine (the rolling machine is specifically a kind of branch wood crushing and crushing device) for crushing and rolling, and flatten the branch wood. , cutting the bamboo into strip-shaped or sheet-shaped units with a thickness of 0.3 mm to 3.0 mm, a width of 5 mm to 20 mm, and a length of 1.95 m, and then rolling and splitting the bamboo unit;

[0030] 2. Drying: Dry the rolled twigs and bamboo chips at a temperature of 40-60°C and a moisture content of 10-16% after drying;

[0031] 3. Ultra-high temperature thermal modification: put the pre-dried bamboo chips and rolled wood into the carbonization treatment equipment, raise the temperature to 80°C at a speed of 8°C / min and keep it warm for 2.5 hours, and then heat it at 10°C / min. Raise t...

Embodiment 3

[0035] The production method of the recombined wooden floor mixed with branch wood and bamboo wood, its steps are as follows:

[0036] 1. Prepare raw materials: Cut the branch wood into a fixed length, such as 1.95m, put it into a rolling machine (the rolling machine is specifically a kind of branch wood crushing and crushing device) for crushing and rolling, and flatten the branch wood. , cutting the fast-growing eucalyptus wood into strip-shaped or sheet-shaped units with a thickness of 0.3mm-3.0mm, a width of 5mm-150mm, and a length of 1.95m;

[0037] 2. Drying: Dry the rolled branch wood and wood chips at a temperature of 40-60°C and a moisture content of 10-16% after drying;

[0038] 3. Ultra-high temperature heat modification: Put the pre-dried and rolled branch wood into the carbonization treatment equipment, raise the temperature to 80°C at a speed of 8°C / min and keep it for 2 hours, and then heat it at a speed of 10°C / min The wood is heated to 190°C and kept for 150 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com