Industrial hydraulic oil refrigerating machine cooling method for equipment heat source

A technology of hydraulic oil and refrigerators, which is applied in the direction of refrigerators, mechanical equipment, and machine operation methods. It can solve the problems of hydraulic system performance degradation, inability to guarantee the normal operation of machinery and equipment, and equipment stability degradation. It achieves convenient operation, Good cooling effect and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

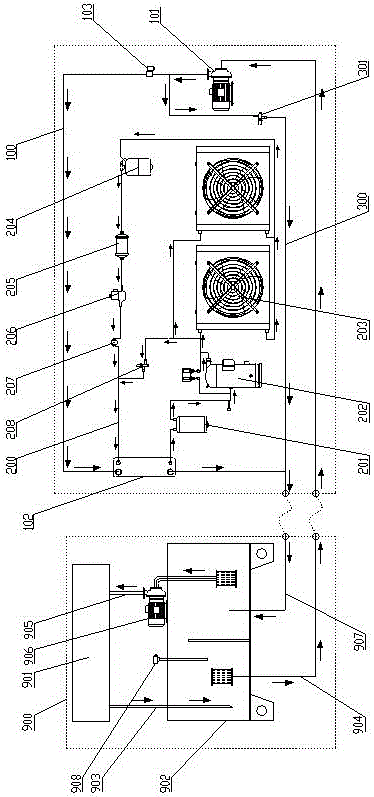

[0022] see figure 1 , an industrial hydraulic oil refrigerator related to the present invention, which includes a hydraulic oil delivery pipeline 100, on which hydraulic oil delivery pipeline 100 is sequentially provided with hydraulic pressure from the hydraulic oil inlet to the hydraulic oil outlet. The oil delivery pipeline transports the pump 101 and the heat exchange device 102, and the cooling pipeline 200 between the cooling outlet of the heat exchange device 102 and the cooling inlet is provided with a gas-liquid separator 201, a compressor 202, a condenser 203, Liquid receiver 204, dry filter 205, cooling pipeline solenoid valve 206 and throttling device 207, wherein there can be one condenser 203, and multiple condensers 203 can also be arranged in parallel or in series, from compressor 202 to condenser 203 A cooling pipeline bypass valve 208 is provided between the cooling pipeline 200 and the cooling pipeline 200 between the throttling device 207 and the heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com