Heat accumulating type pure air heating system with constant outlet temperature

A technology of outlet temperature and air heating, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., and can solve problems such as unadjustable high-temperature air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

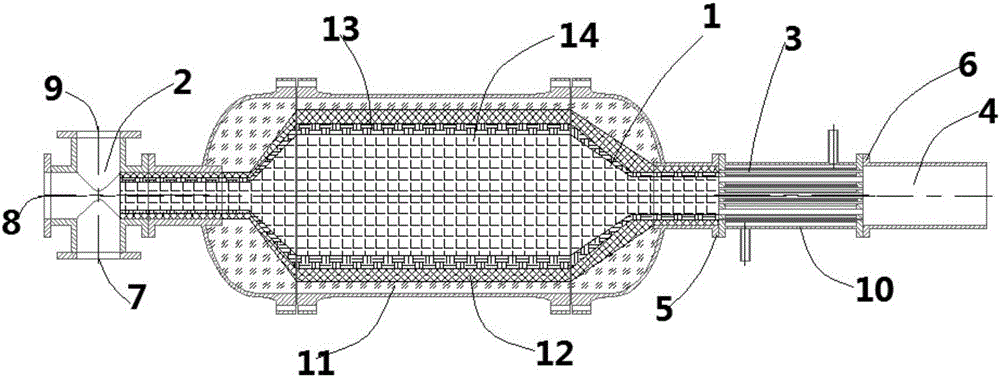

[0024] figure 1 It is a schematic structural diagram of a high-temperature, high-pressure pure air regenerative heating system with adjustable outlet temperature. The temperature range of high-temperature and high-pressure air is 600-1500K, and the pressure range is 1-3.5MPa.

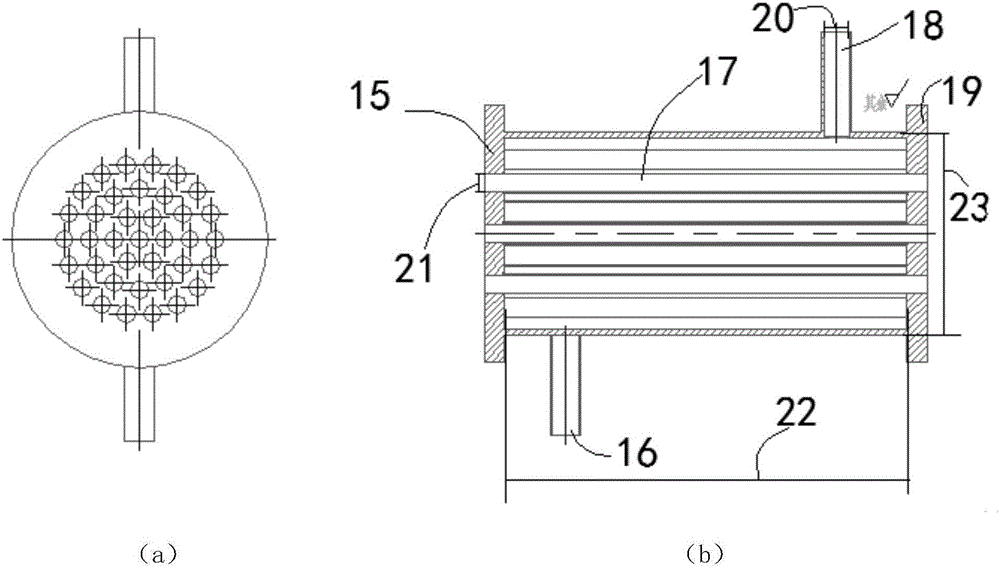

[0025] The invention includes a heat accumulator 1, a burner 2, a pipeline heat exchanger 3, a high-pressure air inlet 7, a liquefied petroleum gas inlet 8, and a fan air inlet 9. The burner 2 is installed at the front end of the heat accumulator 1, and the tail is connected to the front end of the heat accumulator 1. The burner 2 has three interfaces, which are the inlet 7 of high-pressure air, the inlet 8 of liquefied petroleum gas, and the inlet 9 of fan air; the pipe heat exchange The device 3 is installed behind the heat accumulator 1 and placed horizontally.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Under pressure | aaaaa | aaaaa |

| Withstand temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com