Sintering machine head bellows

A technology of sintering machine and machine head, which is applied in the field of metallurgy, and can solve problems such as the clogging of the gap of the flap, the increase of the flue gas flow rate, and the reduction of the life of the bellows, so as to prevent particle clogging, reduce scouring loss, and reduce the possibility of scouring and clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

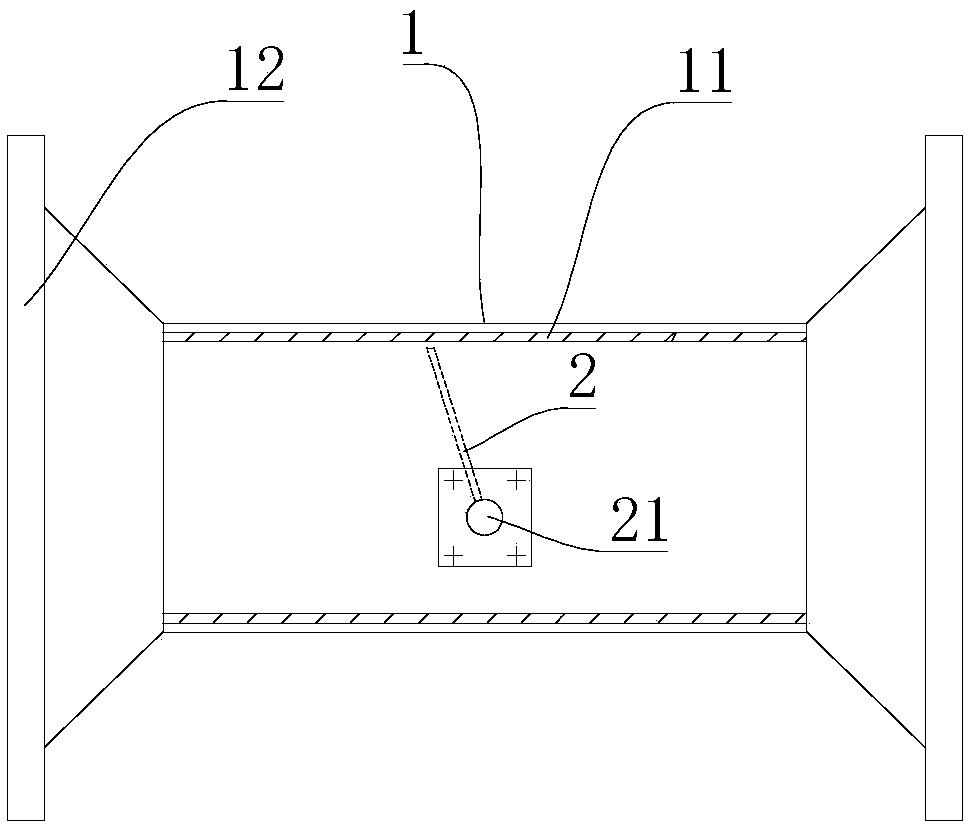

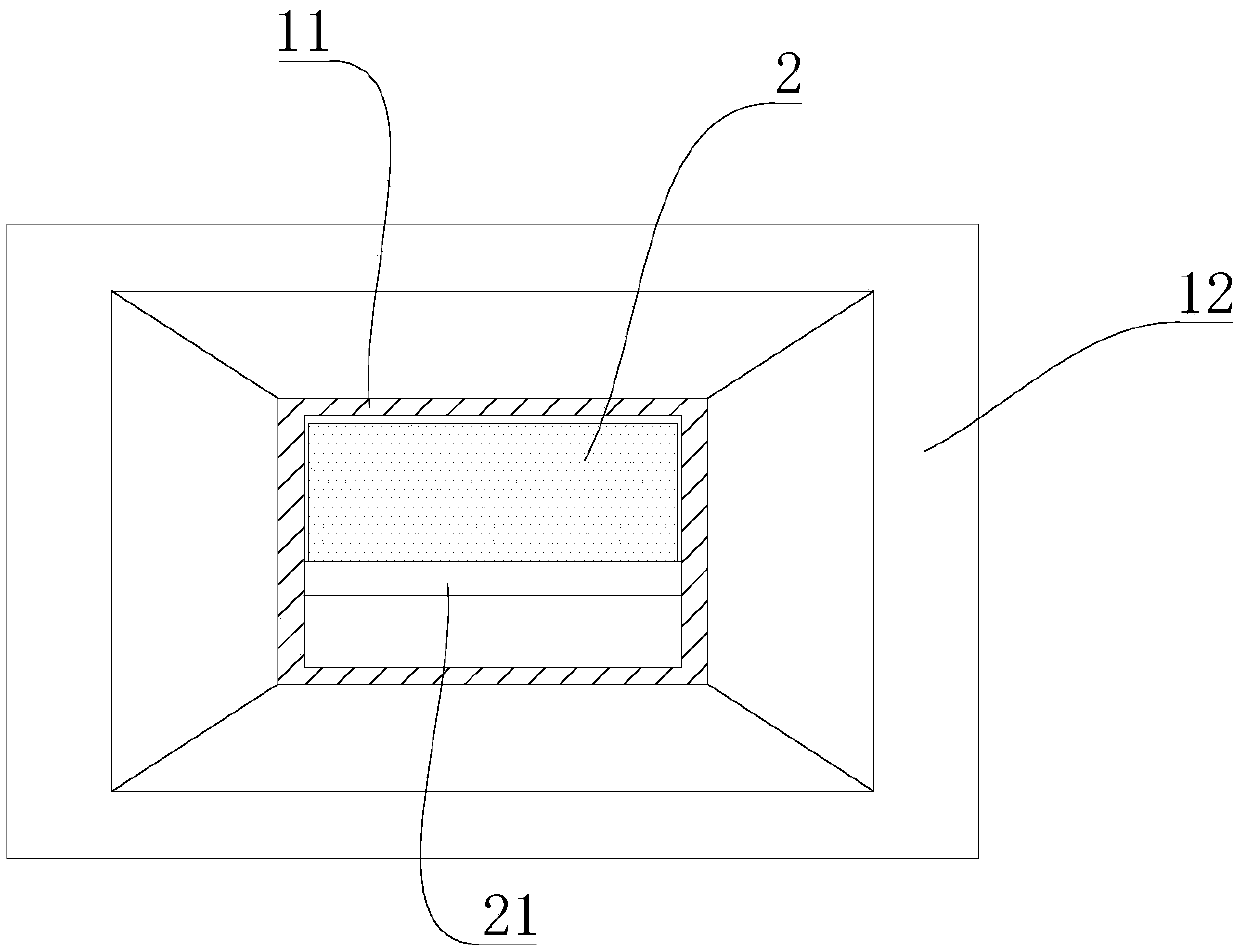

[0013] The bellows of the sintering machine head includes a pipe 1, flanges 12 are connected to both ends of the pipe 1, the pipe 1 is a rectangular pipe, the inner wall of the pipe 1 is provided with a wear-resistant ceramic lining plate 11, and the inner wall of the pipe 1 is A flap 2 is provided, and the shape of the flap 2 is a rectangle adapted to the lumen of the pipeline 1. A rotating shaft 21 is connected to one side of the flap 2. Both ends of the rotating shaft 21 are rotatably matched with the pipeline 1. Adhere to the lumen wall of pipeline 1.

[0014] Such as figure 1 , 2 As shown: the bellows of the head of the sintering machine is provided with a wear-resistant ceramic lining plate 11 on the inner wall of the pipeline 1. The wear-resistant ceramic lining plate 11 is made of alumina as the main raw material and rare metal oxides as the flux. Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com