Casing pipe type condenser cleaning device

A technology for cleaning devices and condensers, applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve the problems of affecting heat exchange efficiency, excessive power consumption, rising energy consumption, etc., to save cleaning space and time, reducing material and labor costs, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be made below in conjunction with drawings and embodiments.

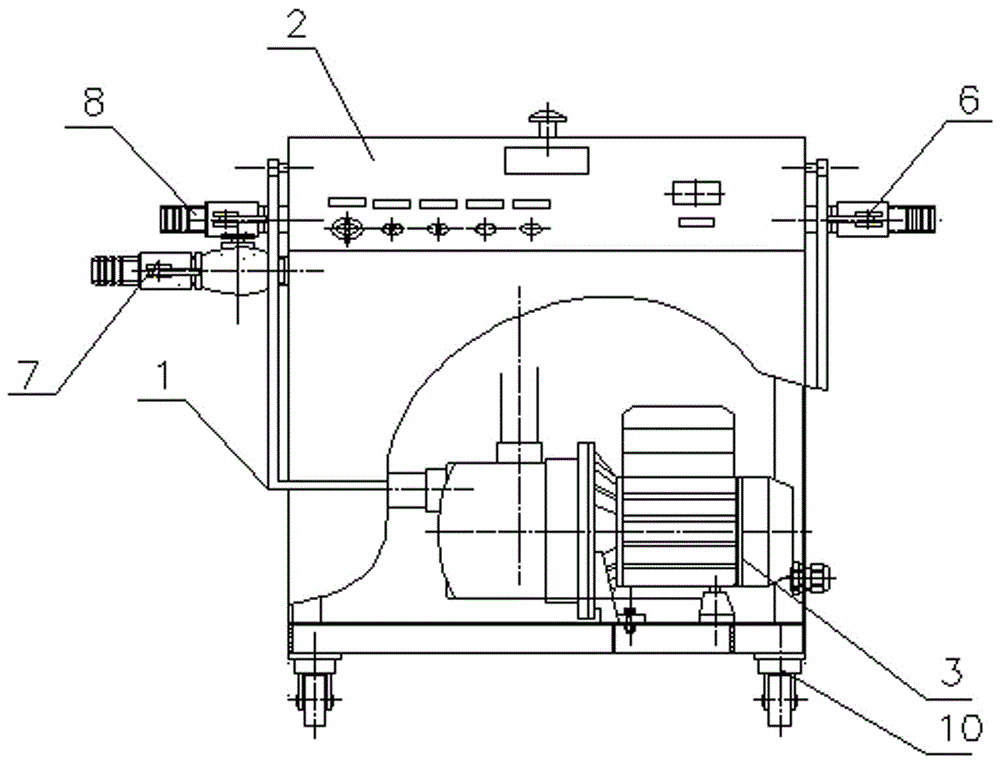

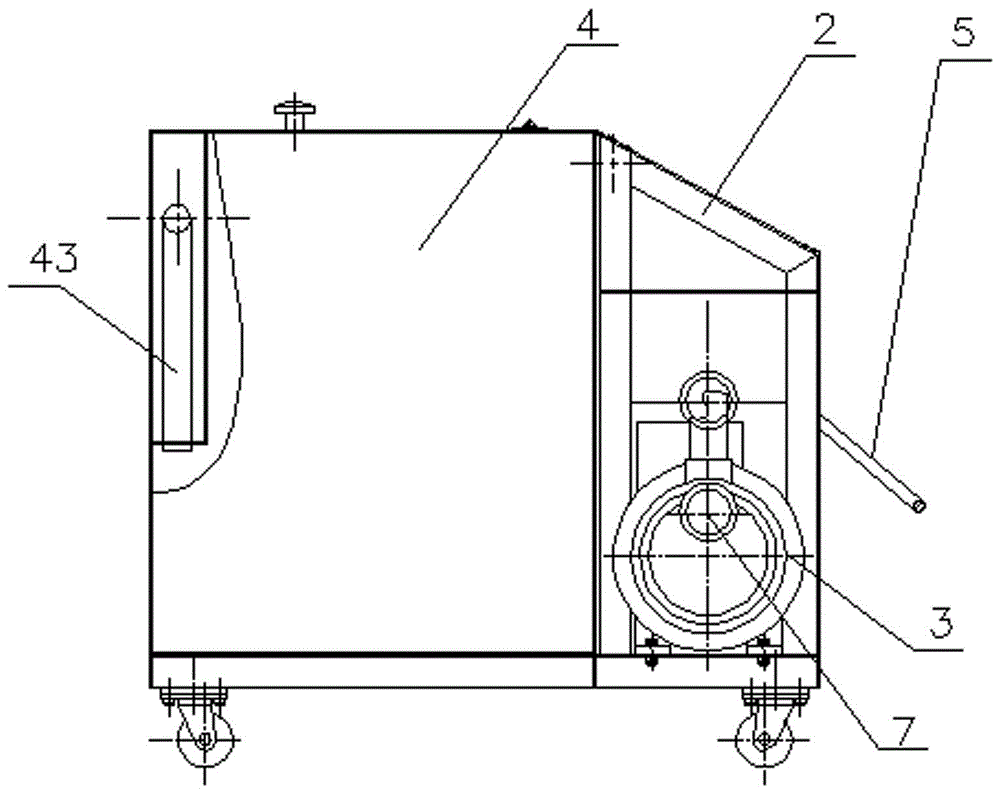

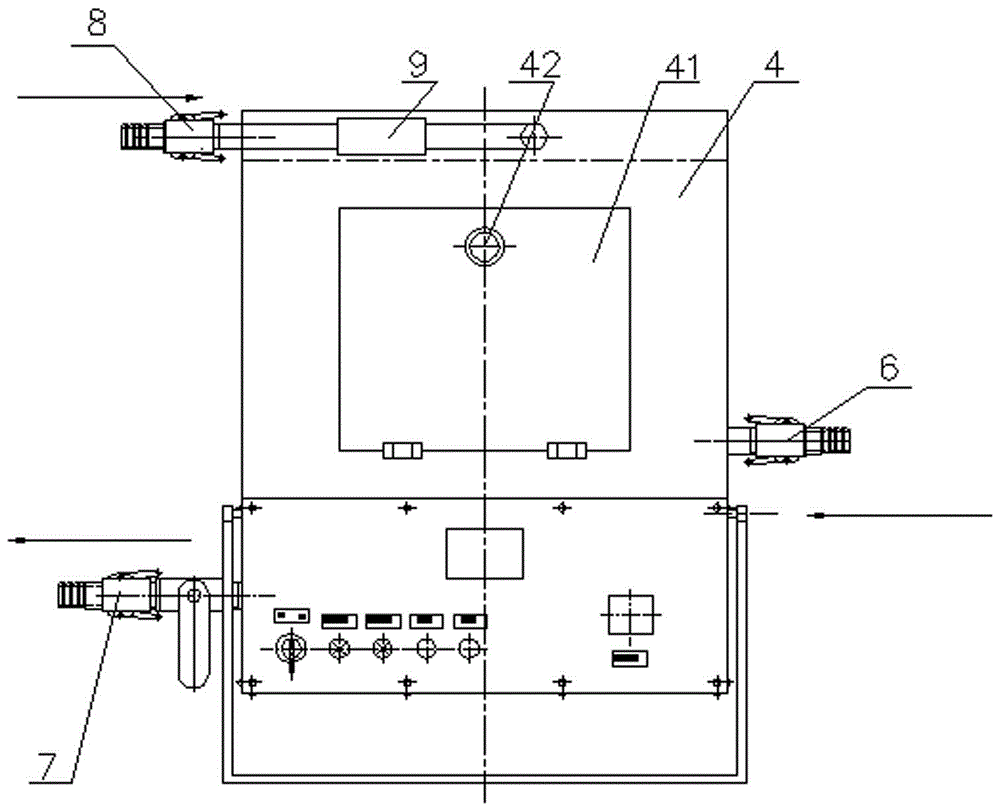

[0020] Figure 1-3 Shown: a casing type condenser cleaning device, including a box body 1, casters 10, a control panel 2, a water pump 3 and a water tank 4, the box body 1 is provided with a handle 5, and the control panel 2 is arranged on the box body 1, The casters 10 are arranged at the bottom of the box body 1, the water pump 3 and the water tank 4 are arranged in the box body 1, and the box body 1 is provided with a water inlet joint 6, a water outlet joint 7 and a water return joint 8, and the water inlet joint 6 is connected to the water tank 1, The water tank 4 is connected to the water outlet joint 7 through the water pump 3, and the return water joint 8 is connected to the water tank 4 through the filter 9. The water tank 4 is provided with a water tank cover 41 with a handle 42, and the tank body is provided with a liquid level mirror 43 connected to display the water level...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap