Radius tip electrode and spherical capacitance return difference type liquid level switch with radius tip electrode

A spherical electrode, spherical electrode technology, applied in the physical variable measurement of liquid level indicator, liquid level indicator, liquid/fluid solid measurement and other directions, can solve the problem of epoxy resin insulation poor pressure resistance, foaming float water absorption High rate, low precision of liquid level switch, etc., to achieve the effect of unaffected sensitivity, compact structure and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

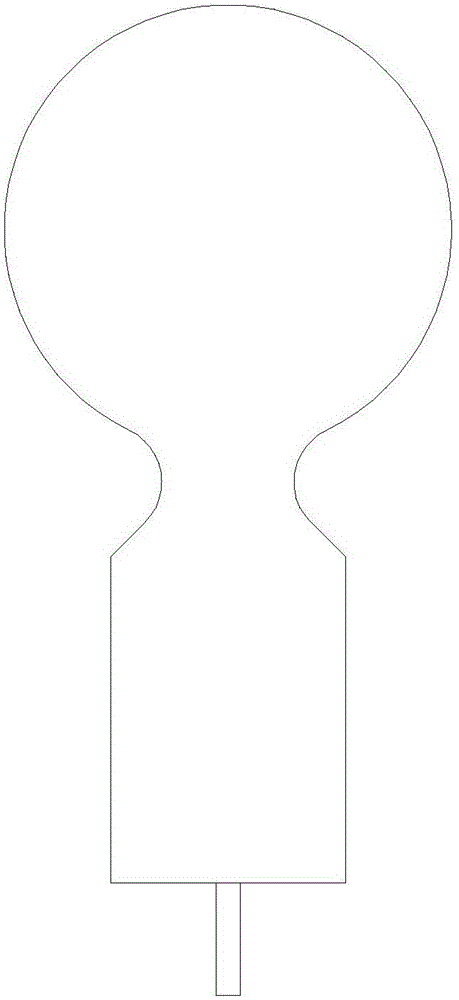

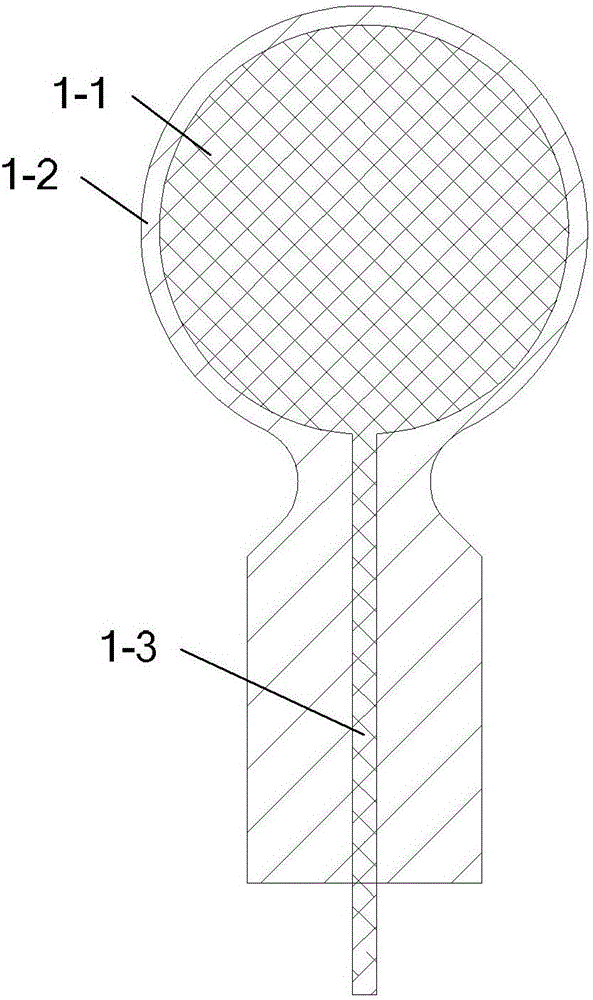

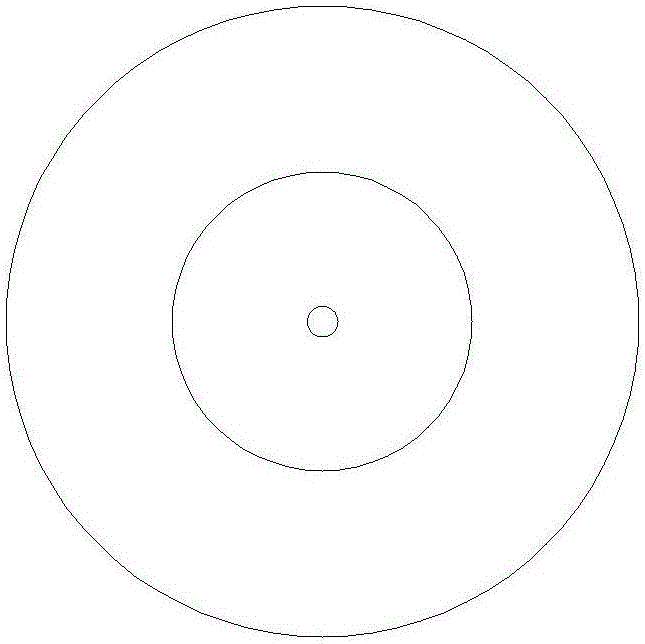

[0032] Specific implementation mode one: refer to Figure 1 to Figure 4 Describe this embodiment in detail, the spherical electrode described in this embodiment includes: a metal spherical electrode 1-1, an insulating layer 1-2 and a terminal post 1-3;

[0033] One end of the terminal 1-3 is in contact with the outer surface of the metal spherical electrode 1-1, and the outer surface of the metal spherical electrode 1-1 and the terminal 1-3 is wrapped with an insulating layer 1-2, and the insulating layer 1-2 wraps the metal The spherical electrode 1-1 is sealed with the terminal 1-3, and the other end of the terminal 1-3 is located outside the insulating layer 1-2, serving as the terminal of the spherical electrode.

[0034] In this embodiment, in practical application, the spherical electrode is located in the working liquid tank, and functions as a capacitive electrode for measuring the position of the liquid level. Inside the spherical electrode, the outer surface of the ...

specific Embodiment approach 2

[0035] Embodiment 2: This embodiment is a further description of the spherical electrode described in Embodiment 1. In this embodiment, the terminals 1-3 are metal terminals.

specific Embodiment approach 3

[0036] Specific embodiment 3: This embodiment is a further description of the spherical electrode described in specific embodiment 1. In this embodiment, the insulating layer 1-2 is divided into an electrode part and a terminal part, and the electrode part is wrapped in a metal spherical electrode 1 On the outside of -1, the terminal part is wrapped on the outside of terminal 1-3, the thickness of the electrode part is smaller than the thickness of the terminal part, and the thickness of the electrode part is uniform.

[0037] In this embodiment, the thickness of the outer insulating layer wrapping the metal sphere part is relatively thin, and the thickness distribution is required to be uniform; the outer insulating layer wrapping the terminal part can be thicker; the entire outer insulating layer part is required to be sealed reliably, and the measured liquid is not allowed infiltrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com