Multifunctional coal sample heating oxidizing rule testing platform capable of achieving automatic sampling

A test platform and automatic sampling technology, which is applied in sampling devices, fuel oil testing, measuring devices, etc., can solve problems such as the complexity of downhole gas components, high-temperature gas overflowing and hurting people, and one-sided test results, so as to reduce human errors and achieve good results Airtightness, the effect of improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a multi-functional testing platform for automatic sampling of coal sample heating and oxidation laws. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

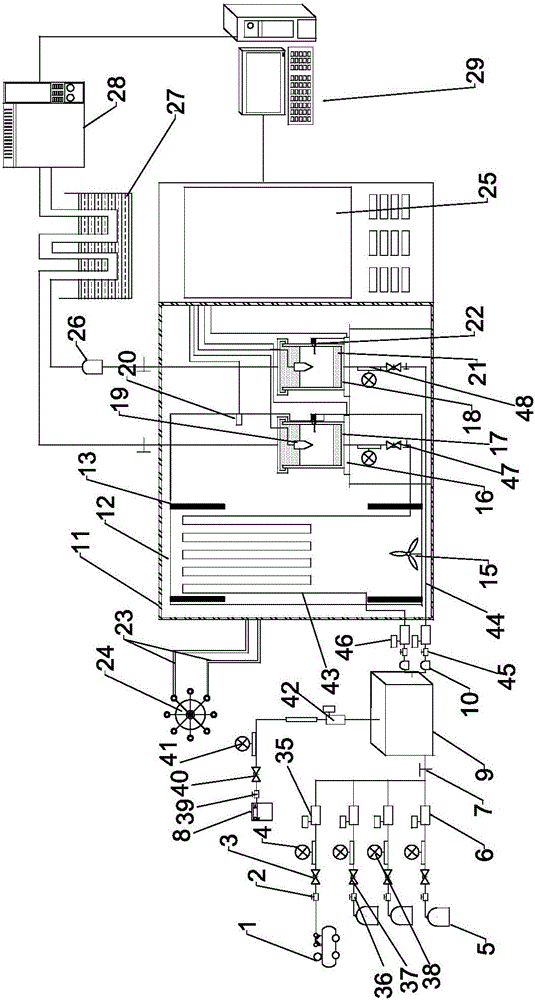

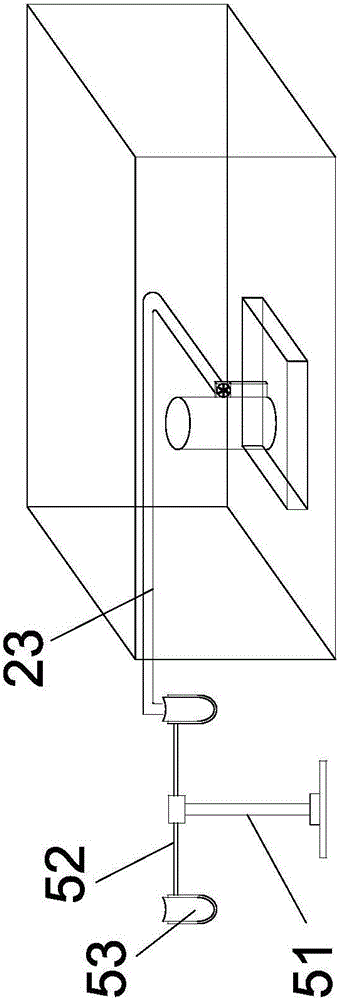

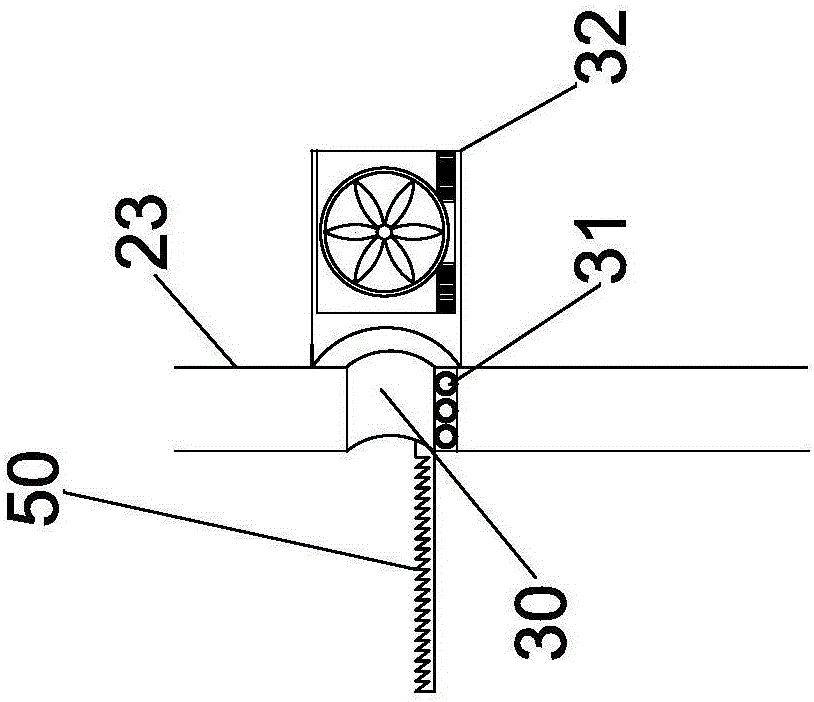

[0021] The invention provides a multi-functional testing platform for the law of heating and oxidation of coal samples with automatic sampling, such as figure 1 As shown, it includes a control center for controlling the operation of the test platform, which is characterized in that it includes:

[0022] The gas distribution inlet part is used to automatically control the flow rate and ratio of various gases that will flow into the device, mix them, and then introduce the mixed gas into the corresponding test operation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com