Annular permanent magnetism gearless ball mill direct drive motor

A direct-drive motor, annular permanent magnet technology, applied in electromechanical devices, synchronous motors with static armatures and rotating magnets, magnetic circuits, etc. problems, to achieve the effect of extending the maintenance cycle and service life, reducing the work intensity and reducing the floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited by the following detailed description.

[0035] The motor provided by the invention can be used in equipment with a rotating cylinder. Such as cement mixer truck, drum mill, drum dryer, washing machine, centrifuge and so on. The combination of the direct drive motor in the ball mill will be described in detail below.

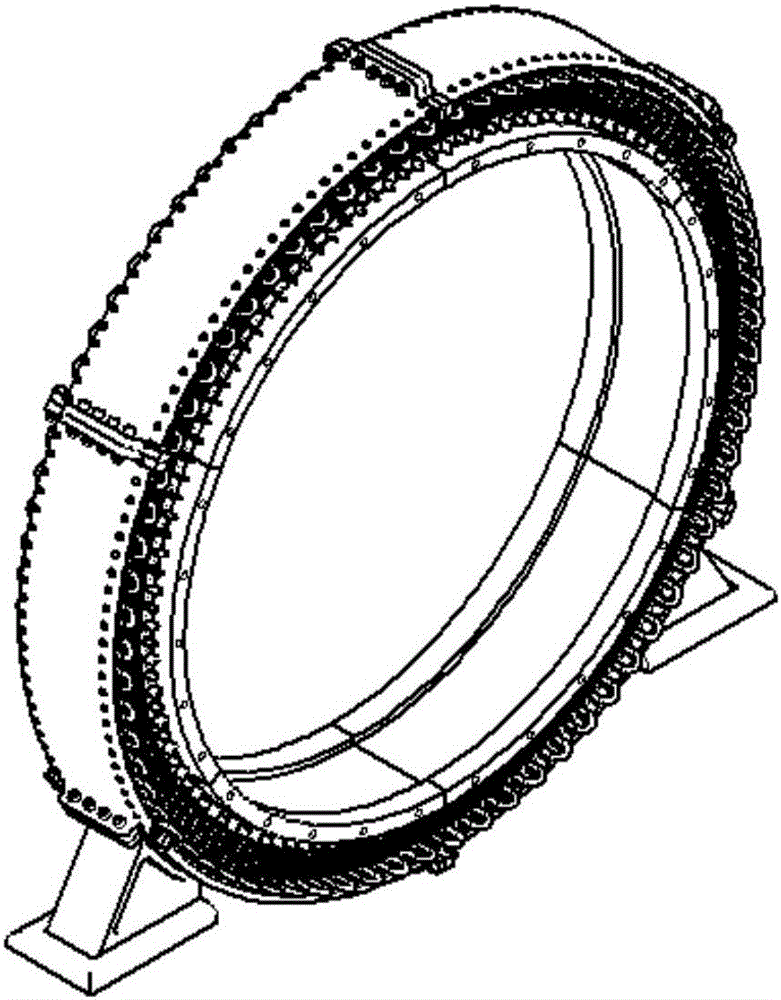

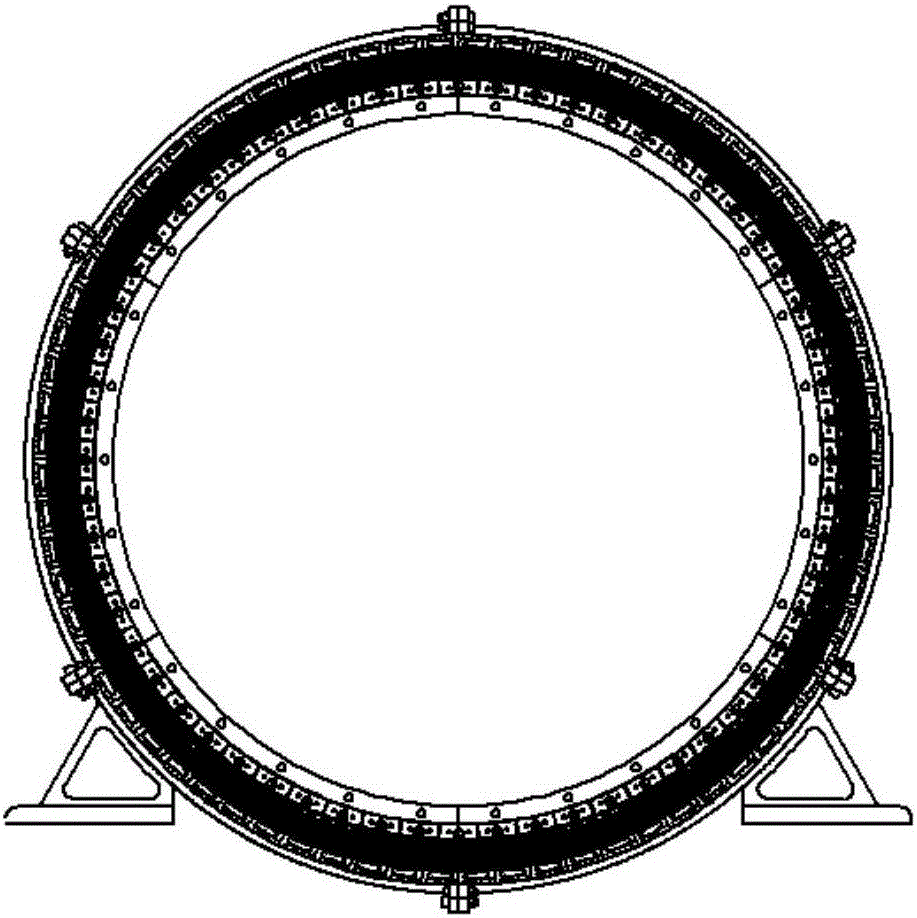

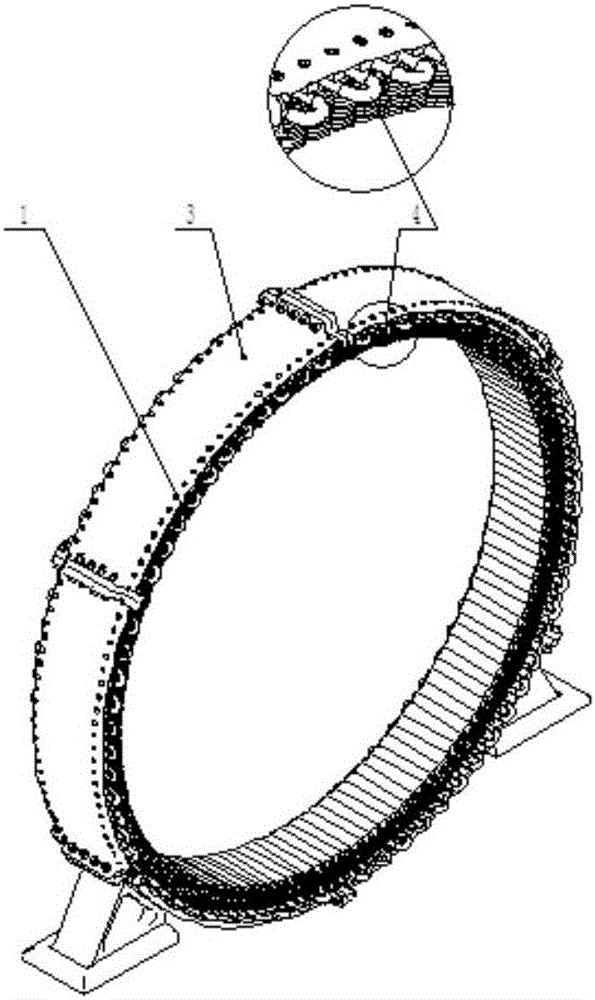

[0036] in, figure 1 It is a schematic diagram of the three-dimensional structure of the direct drive motor in a preferred solution of the present invention (omitting the protective cover and the control device), figure 2 It is a schematic diagram of the front view structure of the direct drive motor, image 3 is a schematic diagram of the stator structure, Figure 4 A schematic diagram of the device structure. Figure 5 Partial sectional view of the direct drive motor provided by the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com