Transistor drive control method of push-pull converter and controller thereof

A drive controller and drive control technology, applied in control/regulation systems, DC power input conversion to DC power output, instruments, etc., can solve the problems that the capacitance cannot be set too large, the production efficiency is low, and the transformer production requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

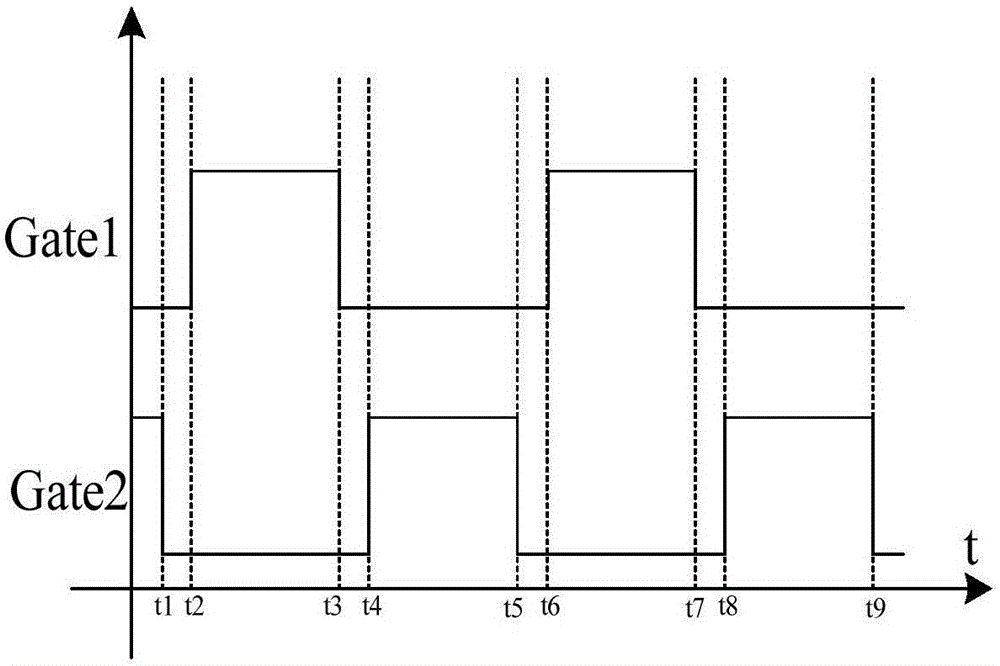

[0049] In order to make it easier for people to understand the transistor driving control method of the push-pull converter of the present invention, this embodiment uses a control flow chart to describe the control process in detail, as Figure 4 As shown, it is easy to see that there are 3 cyclic states, which are in different cyclic states under different working conditions:

[0050] When the converter is just started, the voltage of the output capacitor is zero, and the converter first enters the first cycle state, that is: start → select the current-limiting driving mode → determine the power tube driving mode as current-limiting driving → follow the current-limiting driving mode Drive the selected power tube → detect the conduction voltage drop of the power tube → determine that the voltage drop is greater than the set value → record that the number of overvoltages increases by 1 → the number of times does not exceed the set value → select the current limiting drive again...

Embodiment 2

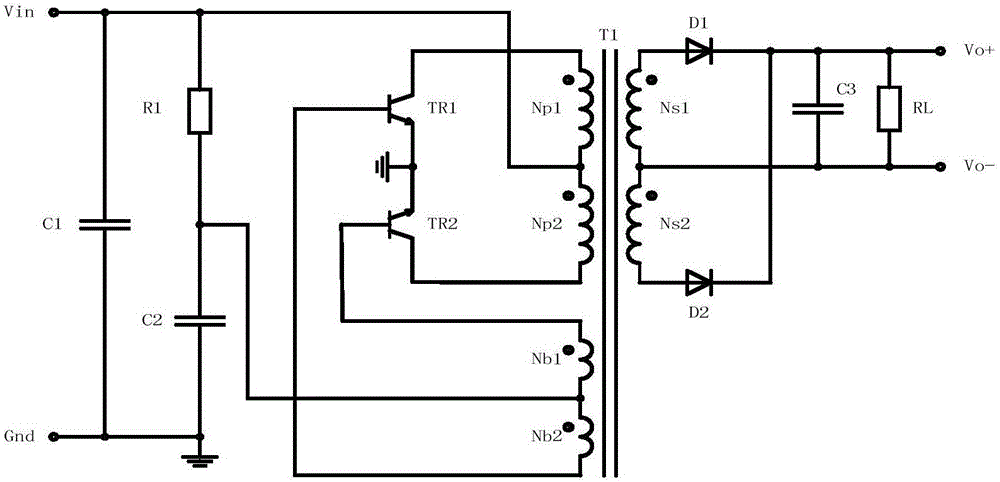

[0059] Such as Image 6 The part of the dashed box 200 shown is the transistor drive controller of the push-pull converter of the present invention. Compared with the first embodiment, the difference of this embodiment is that the driven power transistor is a triode. Because the triode is a current-driven device, the corresponding driving power supply module becomes a driving current module, which provides a small driving current in the current-limited working state, and it provides a large enough driving current in the fully driving state to make the triode The conduction voltage drop is small enough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com