Bearingless permanent magnet synchronous motor prediction controller and construction method

A permanent magnet synchronous motor and predictive controller technology, applied in the direction of motor generator control, electronic commutation motor control, electromechanical brake control, etc., can solve the problems of flux linkage, torque and suspension force hysteresis, flux linkage, torque and Problems such as large suspension force fluctuations, to achieve fast speed response, make up for the impact of system performance, and excellent dynamic and static performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

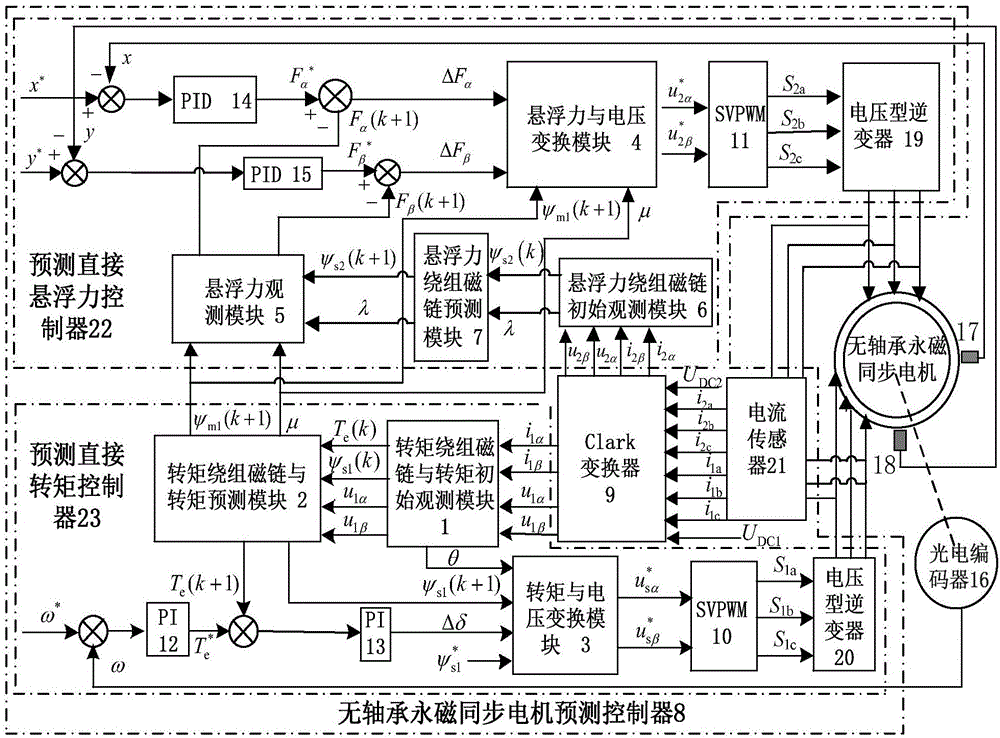

[0020] see figure 1 , the predictive controller 8 of the bearingless permanent magnet synchronous motor of the present invention includes a current sensor 21 , a Clack converter 9 , a predictive direct levitation force controller 22 and a predictive direct torque controller 23 .

[0021] Among them, the predicted direct levitation force controller 22 is composed of voltage inverter 19, SVPWM11 (i.e. space vector pulse width modulation module 11), levitation force and voltage conversion module 4, levitation force winding flux linkage initial observation module 6, levitation force winding Flux linkage prediction module 7, levitation force observation module 5, PID regulator 14 and PID regulator 15 are composed.

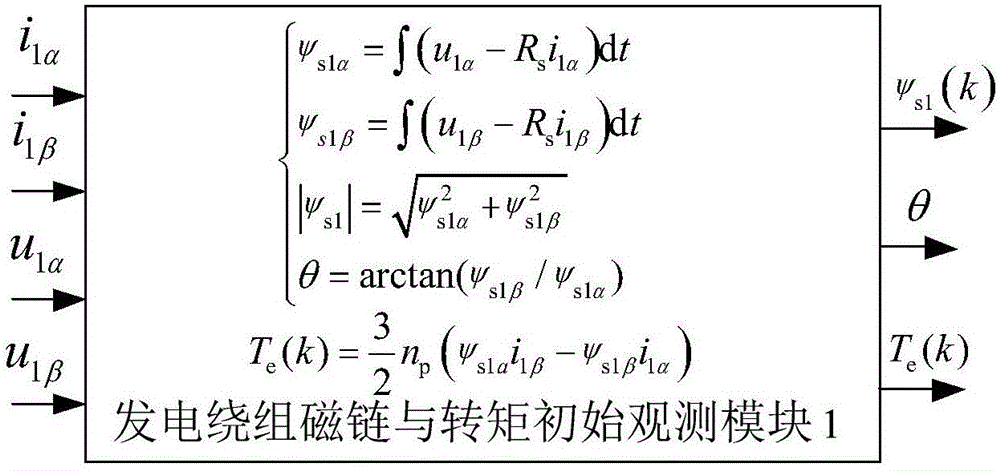

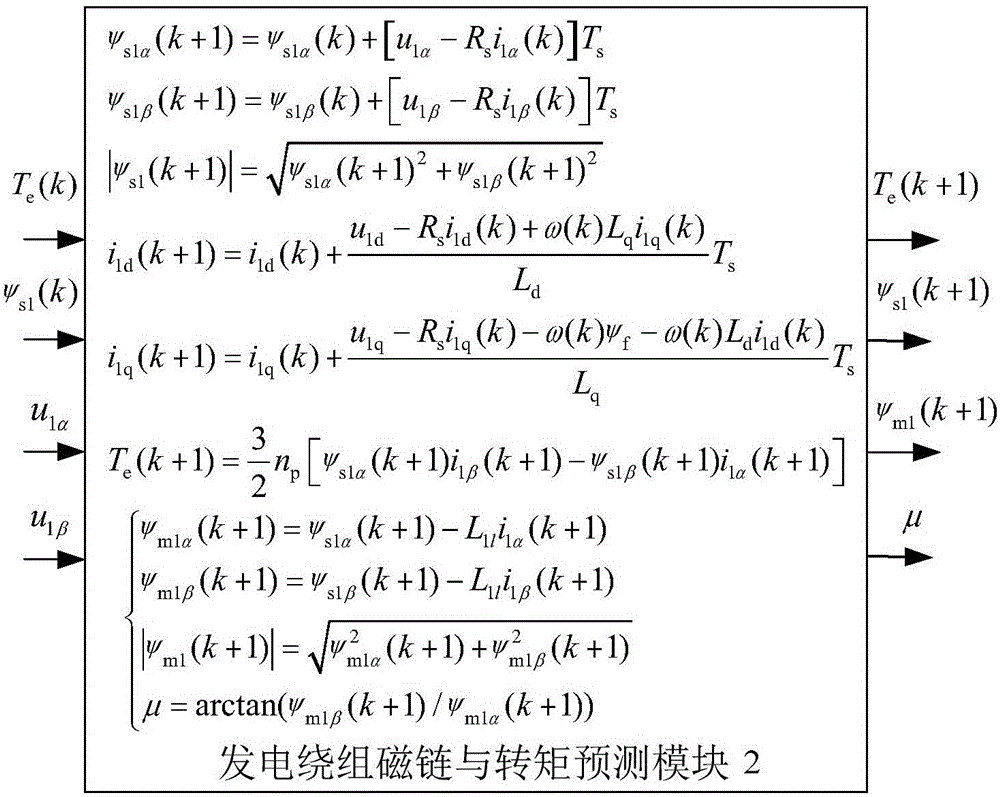

[0022] Predicted direct torque controller 23 is composed of torque winding flux linkage and torque initial observation module 1, torque winding flux linkage and torque prediction module 2, voltage source inverter 20, SVPWM10, torque and voltage conversion module 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com