Manufacturing method for cold insulation cup structure

A manufacturing method and technology for cold cups, which are applied to drinking utensils, household utensils, table utensils, etc., can solve problems such as inability to conform to users, wet desktops, slippery palms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

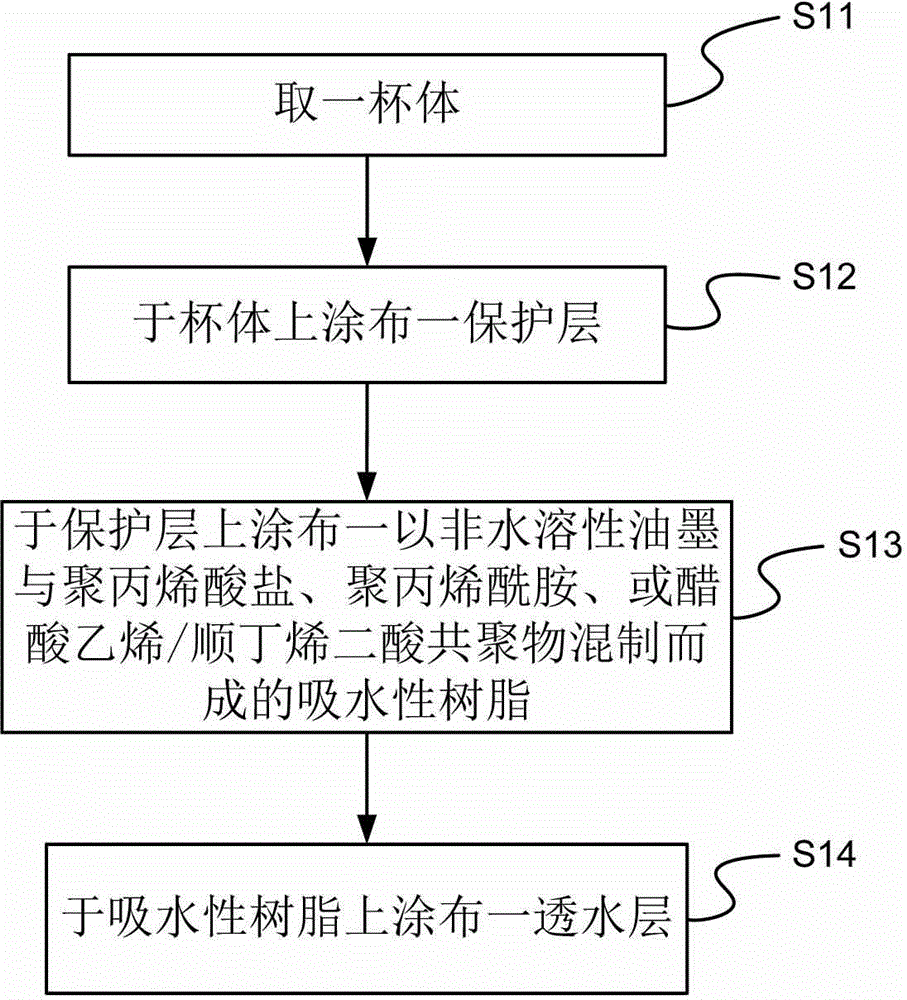

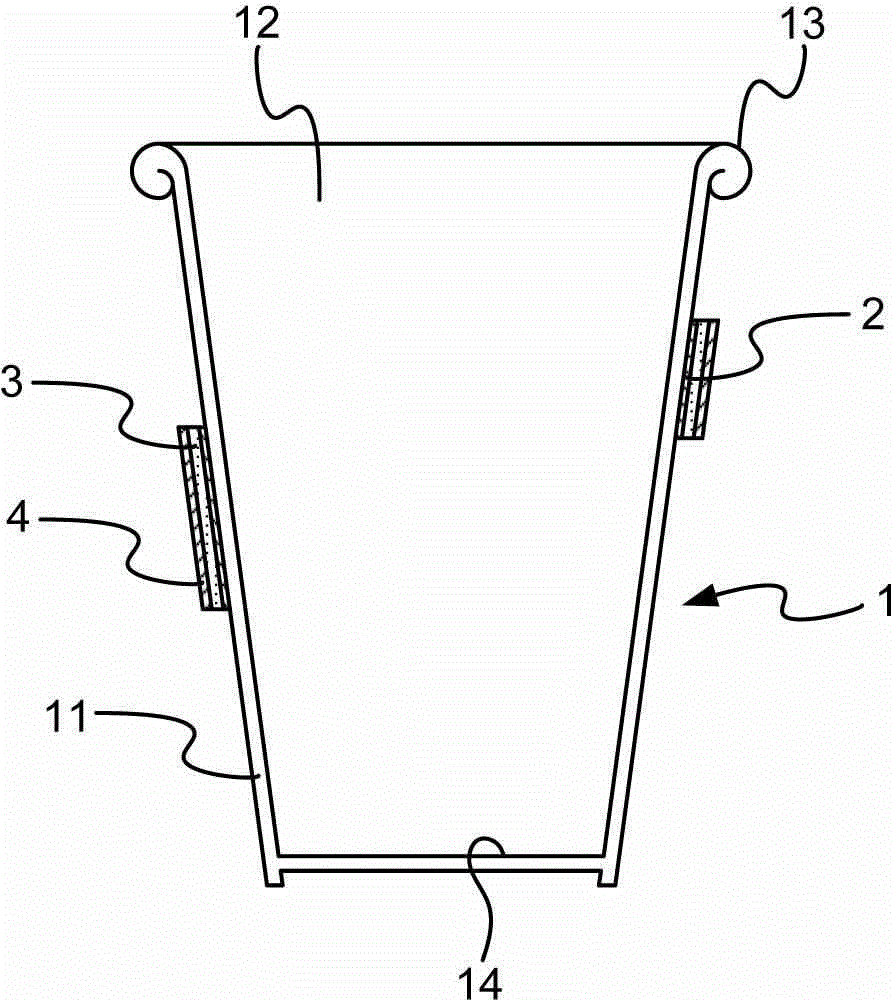

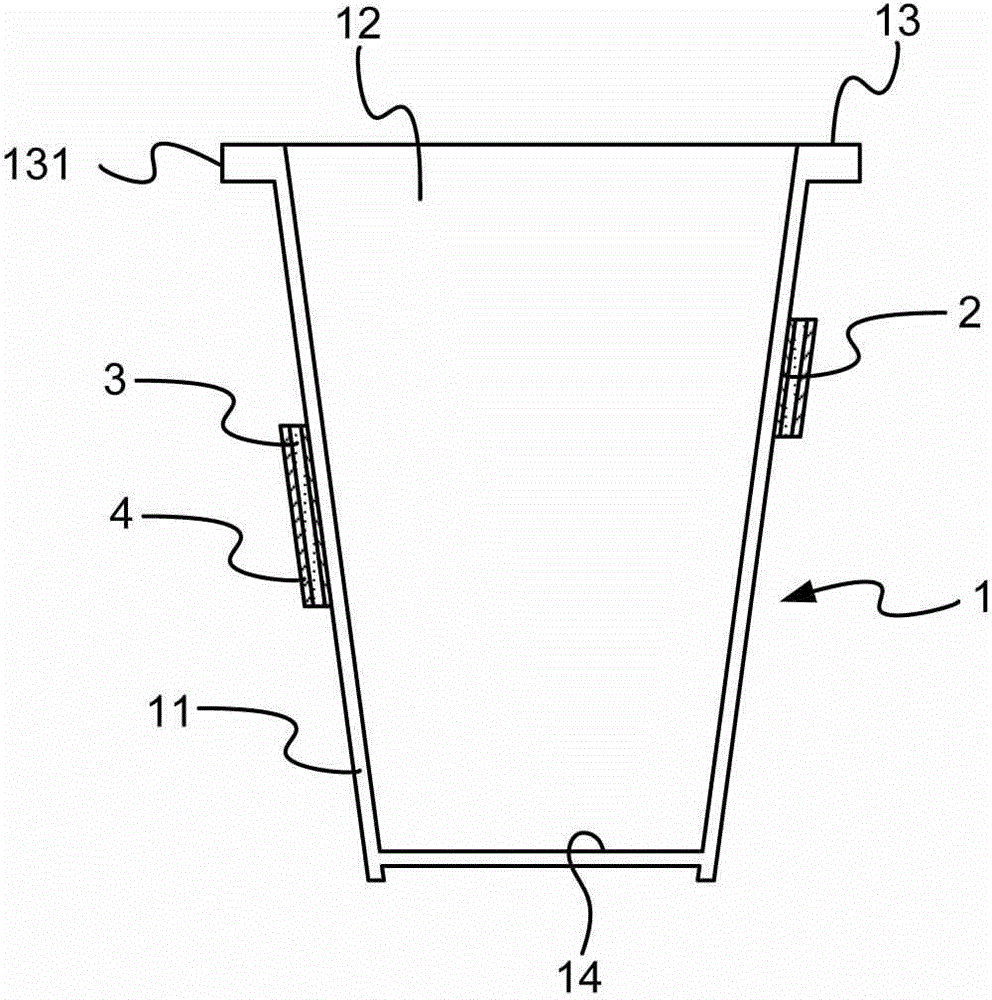

[0028] see Figure 1-Figure 6 As shown, they are respectively a schematic diagram of the manufacturing process of the cold-keeping cup structure of the present invention, a schematic cross-sectional diagram of the cold-keeping cup structure of the first embodiment of the present invention, a schematic cross-sectional diagram of the cold-keeping cup structure of the second embodiment of the present invention, and a schematic cross-sectional diagram of the cold-keeping cup structure of the third embodiment of the present invention. The schematic cross-sectional view of the structure of the cold-preservation cup, the schematic view of the structure of the cold-preservation cup of the present invention before absorbing water, and the schematic view of the structure of the cold-retention cup of the present invention after absorbing water. As shown in the figure: the present invention is a method for manufacturing a cold-keeping cup structure, which at least includes the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com