Device and method for heating and dissolving water-soluble matter through steam ejector

A technology of heating and dissolving and ejector, which is applied in the direction of dissolving methods, driving agitator dissolving, chemical instruments and methods, etc., can solve the problems of slow heat transfer speed, long dissolving time, and potential safety hazards, and achieve the reduction of steam consumption, Improve the dissolution rate, no safety hazard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

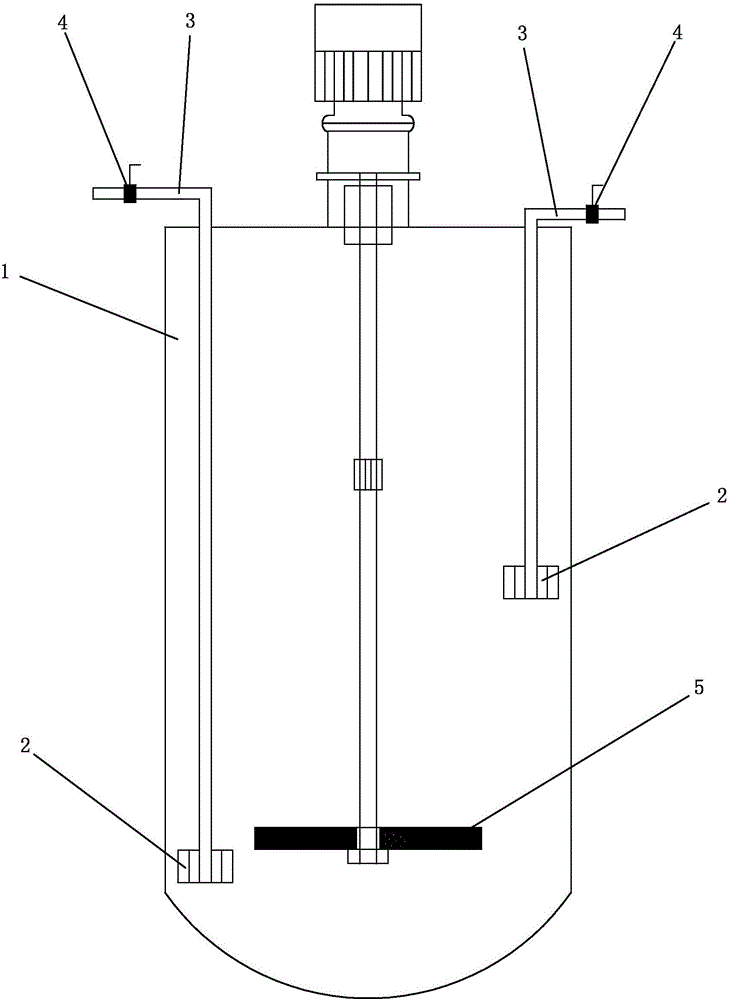

[0027] See figure 1 As shown, a device of the present invention that utilizes a steam injector to heat and dissolve water-soluble substances is used to dissolve water-soluble substances using steam, including a steam pipeline 3, a steam injector 2 and a melting container 1; One end of the steam pipe 3 is connected to a steam source, and the other end of the steam pipe 3 extends into the melting vessel 1 and is connected with the steam ejector 2; The steam transported by the steam pipe 3 is sprayed into the melting container 1 to dissolve the water-soluble substances in the melting container 1 .

[0028] Furthermore, it also includes a stirring paddle 5 , which is installed in the melting container 1 and stirs the closed space inside the melting container 1 . The stirring paddle 5 is driven by a motor, and fully mixes the solution or steam in the melting container 1, and also speeds up the condensation and heat release of the steam.

[0029] Furthermore, there are at least tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com