Radial magnetic jetting liquid magnetic processor

A technology of magnetic jets and processors, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc. The direction cannot be adjusted, the liquid flow cannot be magnetized, etc., to achieve uniform and efficient magnetization, free selection and matching, and the effect of achieving safety and hygiene requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

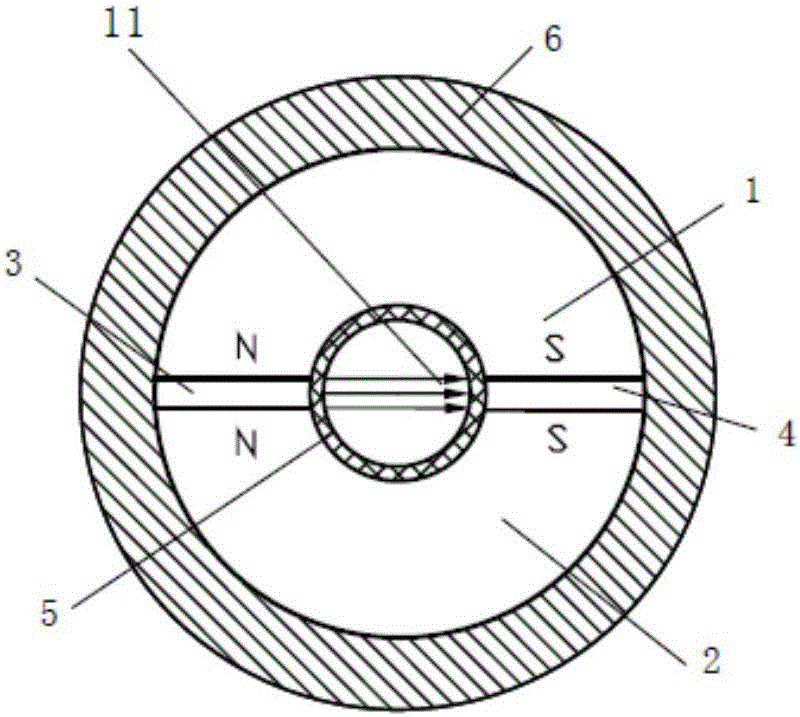

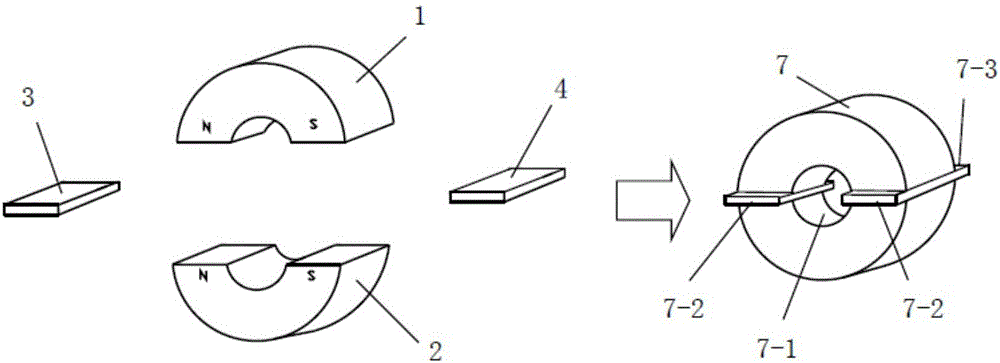

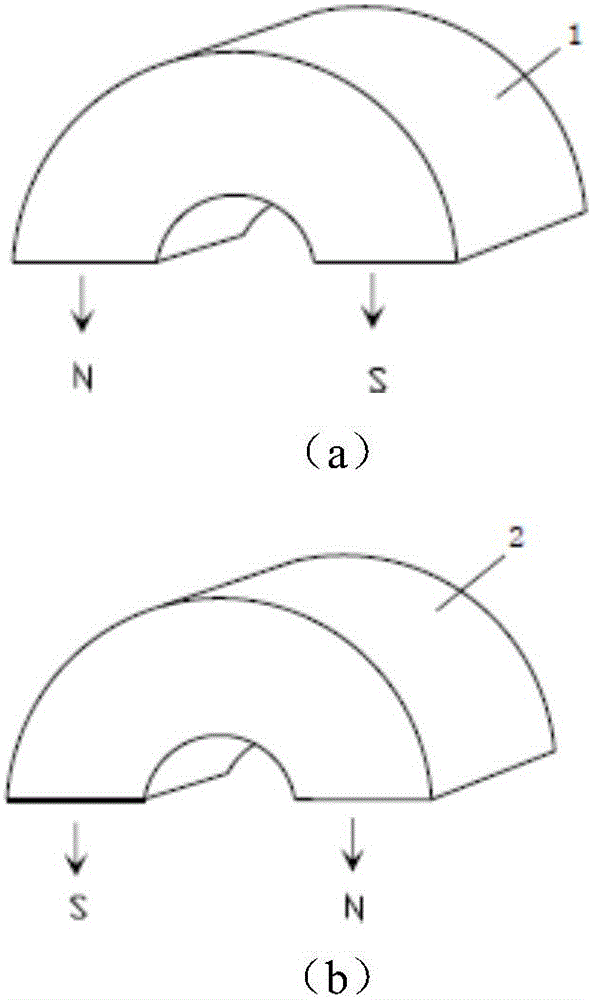

[0041] The simplest structure of the radial magnetic jet type liquid magnetic processor of the present invention is obviously composed of only one magnetic jet generator 7 of a certain length matched with two end circular isolation orifice plates 9 . For the magnetic processor with this structure, the radial magnetic jet 11 will always face the same direction, and there will be problems of magnetic field uniformity and processing effect not optimal for the liquid to be processed.

Embodiment 2

[0043] Figure 8 It is a relatively simple and effective embodiment of the radial magnetic jet liquid magnetic processor of the present invention, the number of the magnetic jet generators 7 is 4, the number of the magnetic jet direction regulators 8 is 3, and the magnetic jet direction regulators There is an included angle of 90° between the diameters of the first groove 8-2 and the second groove 8-3 in 8, so that the direction of the magnetic jet 11 generated by the magnetic jet generator 7 at one end is the horizontal direction, that is, 0°, from From this end, the direction of the magnetic jet 11 generated by the magnetic jet generator 7 rotates 90°, 180°, and 270° in turn. Magnetic treatment effect is better than in embodiment 1, Figure 9 It is a schematic diagram of the adjustment and change of the direction of the magnetic jet along the axial direction of the radial magnetic jet type liquid magnetic processor in this embodiment.

Embodiment 3

[0045] Another more complex embodiment of the liquid magnetic processor of the radial magnetic jet of the present invention adopts 9 magnetic jet generators 7 and 8 magnetic jet direction regulators 8, and the first groove in the magnetic jet direction regulator 8 8-2. There is an included angle of 45° between the diameters of the second groove 8-3. The main magnetic field direction of radial magnetic jet 11 in the present embodiment is successively 0 °, 45 °, 90 °, 135 °, 180 °, 225 °, 270 °, 315 ° and 360 °, the main direction of radial magnetic jet 11 Change in increments of 45° angle. Figure 10 It is a schematic diagram of the adjustment and change of the direction of the magnetic jet along the axial direction of the radial magnetic jet type liquid magnetic processor in this embodiment.

[0046] Obviously, the included angle between the diameters of the first groove 8-2 and the second groove 8-3 in the magnetic jet direction regulator 8, and the number of the magnetic je...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com