Adsorbent for selectively reducing release amount of volatile carbonyl and phenol compounds in cigarette smoke and preparation method and application of adsorbent

A technology of phenolic compounds and cigarette smoke, applied in the direction of chemical instruments and methods, applications, tobacco, etc., can solve the problem of multiple processes for preparing complex materials, reducing the release of various volatile carbonyl compounds and phenolic substances, and complicated procedures and other issues, to achieve the effect of low cost, high safety and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of adsorbent

[0030] 1) Prepare a CuCl solution with a mass fraction of 20% and a PdCl solution with a mass fraction of 10% 2Solution, the two are mixed with a volume of 2:1 to obtain a mixed solution of the two;

[0031] 2) Use a sprayer to evenly spray the mixed solution prepared in step 1) on the surface of activated carbon fibers to obtain a composite material loaded with metal ions Cu and Pd, in which the loadings of Cu and Pd elements are 21.4% and 12.5% of the mass of activated carbon fibers respectively ;

[0032] 3) Dry the composite material obtained in step 2) at 120° C. for 40 minutes to obtain the adsorbent of the present invention.

[0033] 2. Application of adsorbent

[0034] The prepared adsorbent material is made of a coaxial core binary composite filter tip using the existing molding method of cigarette filter rods and cellulose acetate filter rods. The trial production quantity is 8,000 cigarettes, and the adsorbent material conta...

Embodiment 2

[0042] 1. Preparation of adsorbent

[0043] Preparation of CuCl with a mass fraction of 30% 2 solution, use a nebulizer to spray CuCl 2 The solution is evenly sprayed on the surface of the activated carbon fiber to obtain a composite material loaded with metal ion Cu, wherein the loading amount of the Cu element is 13.6% of the mass of the activated carbon fiber; then the composite material is dried at 120 ° C for 40 minutes to obtain the adsorbent of the present invention .

[0044] 2. Application of adsorbent

[0045] The prepared adsorbent material is made of a coaxial core binary composite filter tip using the existing molding method of a cigarette filter rod and a cellulose acetate filter rod. The trial production quantity is 8,000 cigarettes, and the adsorbent material contained in each cigarette is 15 mg.

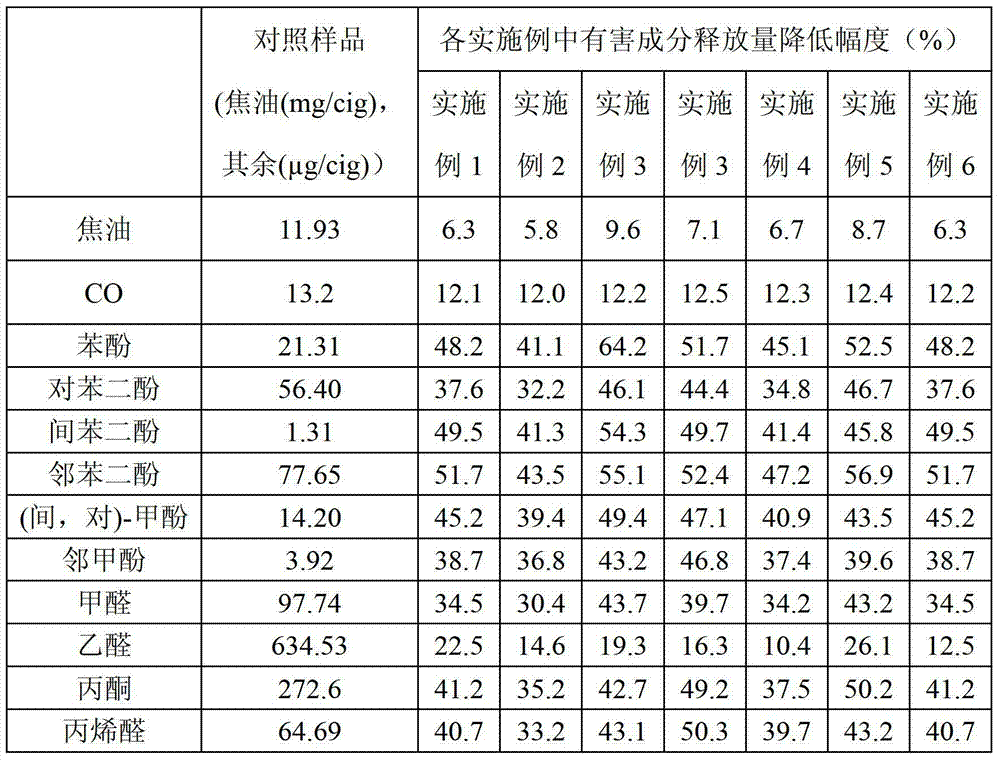

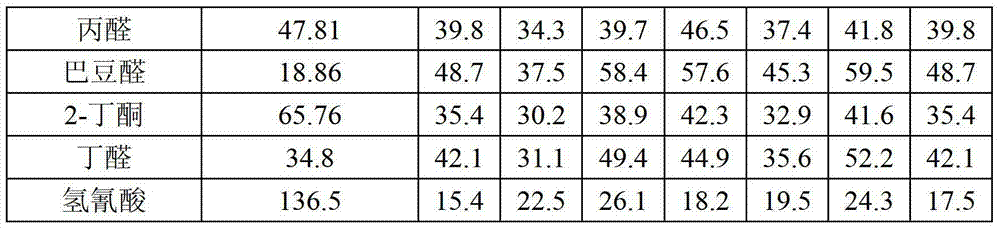

[0046] All the other steps are the same as in Example 1, and the measurement results are shown in Table 1.

[0047] The results show that after the adsorbent is ...

Embodiment 3

[0049] Preparation of NiCl with a mass fraction of 20% 2 The solution was evenly sprayed on the surface of the zeolite molecular sieve with a sprayer, and the Ni element loading was 30% of the mass of the zeolite molecular sieve, and then the composite material was dried at 150°C for 40 minutes. The prepared adsorbent material adopts the existing molding method of cigarette filter rods and cellulose acetate filter rods to make binary composite filter tips. The trial production quantity is 8,000 cigarettes, and the adsorbent material contained in each cigarette is 11 mg. All the other steps are the same as in Example 1, and the measurement results are shown in Table 1.

[0050] The results show that after the adsorbent is applied to cigarettes, it can significantly and selectively reduce the main phenolic compounds and volatile carbonyl compounds in the mainstream smoke, and the content of CO and hydrocyanic acid in the smoke is also reduced. The cigarettes prepared by adoptin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com