Graphite reactor

A graphite reactor and graphite technology, applied in the field of reactors, can solve the problems of unprotected parts, corrosion, and high sealing requirements for joints, and achieve the effects of easy processing and manufacturing, simple sealing structure, and good sealing relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

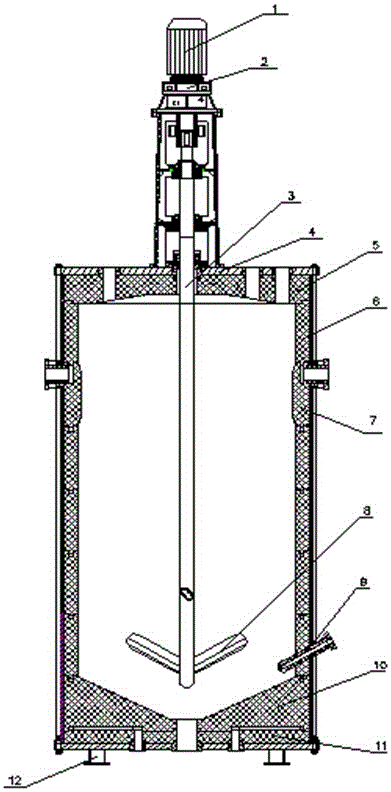

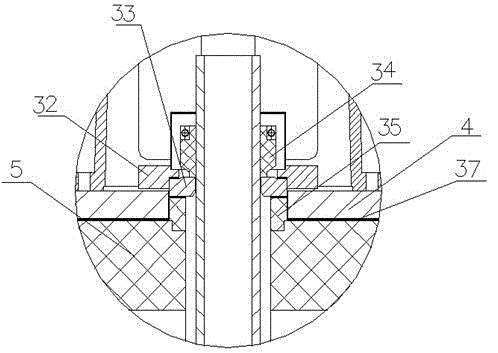

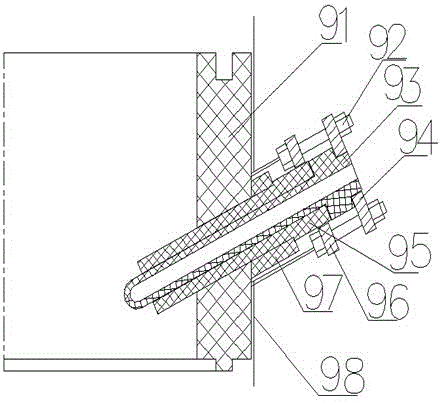

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention discloses a graphite reactor, including a driving stirring device and a reaction cylinder, and the driving stirring device includes an explosion-proof motor 1 located at the upper end of the reaction cylinder, a reducer 2 and a stirring shaft 3 located inside the reaction cylinder, The stirring tooth 8 also includes a sealing structure that is convenient to be connected with the reaction cylinder; the reaction cylinder includes a graphite reactor liner, a steel structure shell, auxiliary legs and a temperature measuring structure, and the graphite reactor liner includes an upper head 5, graphite The inner cylinder 91 and the lower head 11, the graphite inner cylinder 91 includes several coaxially arranged graphite segments 7, a funnel-shaped base 10 located below the graphite segments 7, and a graphite connecting section located at the upper end of the graphit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com