Assembly method of super-large-diameter, stiffening-rib-free and thin-wall hemispherical top seal cover

A technology with super large diameter and assembly method, which is applied in the direction of metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of no stiffener and small head space, etc., to reduce construction cost, improve construction efficiency, ensure construction safety and construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The core device of isocyanate production is located in a steel sealing cover. Since highly toxic intermediate products will be produced during the production process, in order to avoid the leakage of toxic and harmful substances, a steel sealing cover is set outside the device to isolate it from the outside world and form a protection. In order to maximize the utilization of the space in the sealed enclosure and ensure the structural strength and stability of the top cover, this embodiment adopts a hemispherical top.

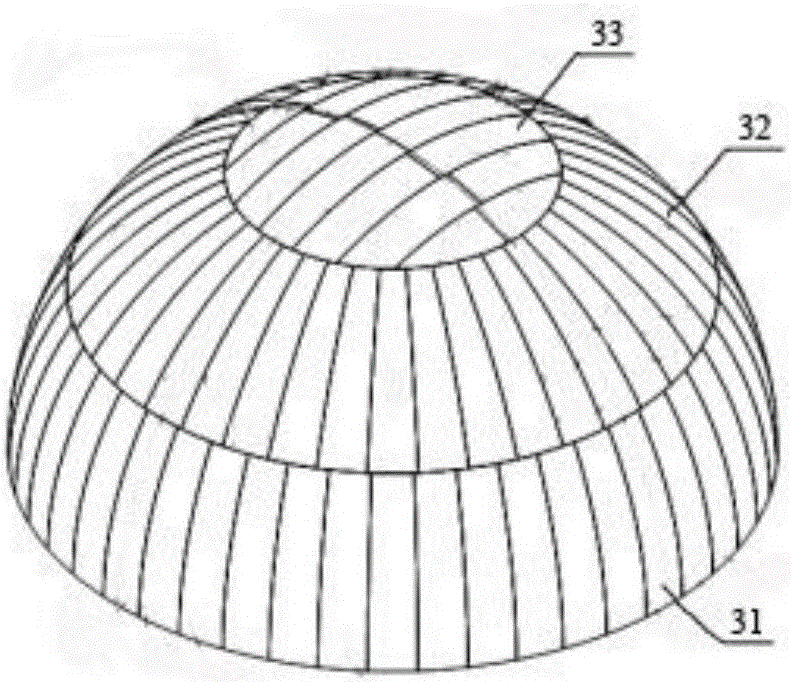

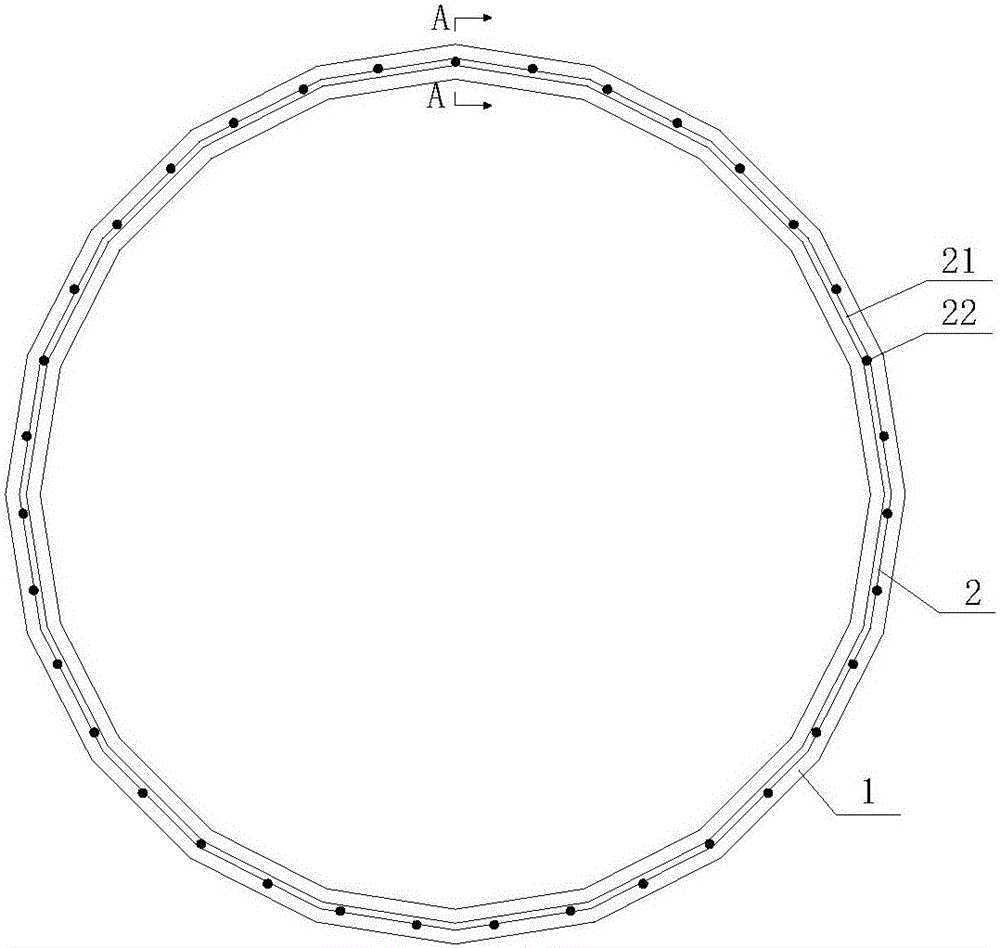

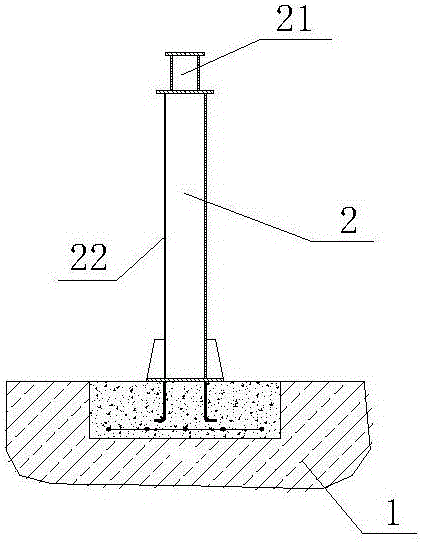

[0062] like Figure 1-15 As shown, a super large-diameter non-stiffener thin-walled hemispherical sealing cover includes a hemispherical dome 3, a cylinder body 5, a wind-resistant ring 6, an embedded plate and a bottom plate, and the hemispherical dome 3 includes an equatorial zone 31, a temperate zone 32 and an upper pole 33 , the equatorial zone 31 is welded by a number of spherical shell plates 311, the temperate zone 32 is welded by a number of spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com