Non-contact power supply track elevated bus and operation method

A non-contact power supply and bus technology, applied in electric locomotives, locomotive propulsion methods, locomotives, etc., can solve problems such as failure to achieve expected results, crowding, etc., to achieve low investment and operating costs, speed up traffic flow, comfortable and safe rides. The effect of the car environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing, the present invention will be further described:

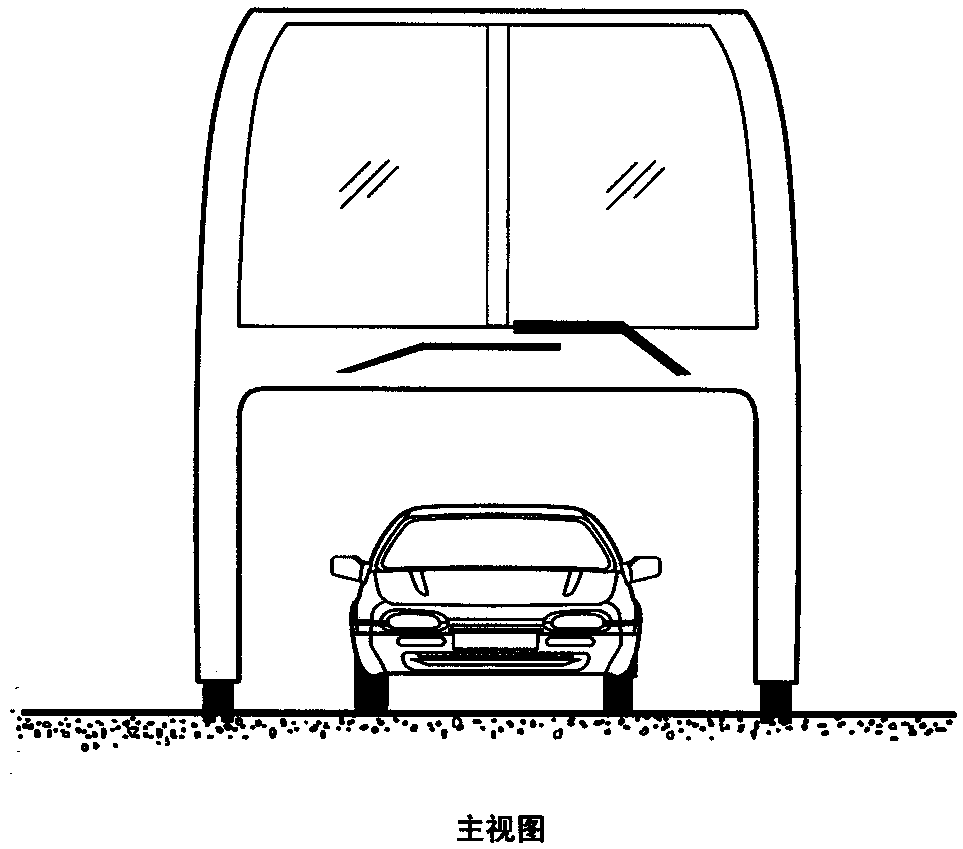

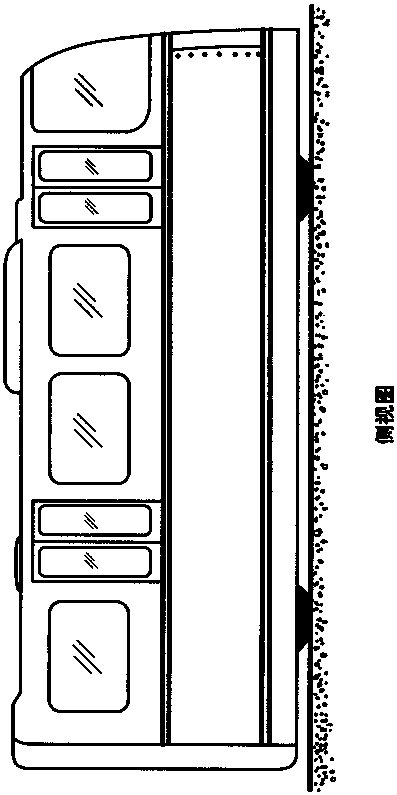

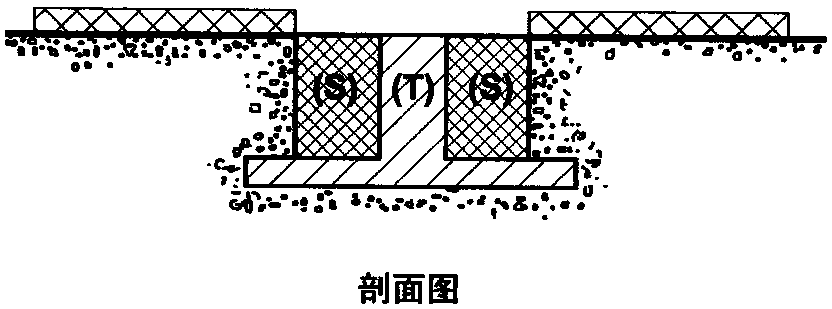

[0046] An elevated bus with non-contact power supply. figure 1 ) (attached figure 2 ).

[0047] The upper compartment houses the passenger cabin and control room. The passenger compartment is roomy, with seating set up to a high standard. There is a traffic information display in the passenger compartment. The car is equipped with an air purification device, and the roof is equipped with a sunroof, so that the light in the car is sufficient. Doors are provided at the front and rear on the right side of the compartment for passengers to enter and exit. There is an operating console in the control room, and the driver controls the driving of the vehicle through the intelligent control device.

[0048] The bottom of the left and right side panels of the lower frame of the vehicle body is equipped with in-wheel motor wheels, which are driven by a non-contact external po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com