A kind of method for preparing hierarchical porous titanium silicon molecular sieve

A titanium-silicon molecular sieve and multi-stage pore technology, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the difficulties in the treatment of inorganic salts and inorganic alkalis, the loss of molecular sieve quality and crystallinity, and the macromolecular reaction performance of molecular sieves have not been effectively improved. and other problems, to achieve the effect of high crystallinity and high macromolecular reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

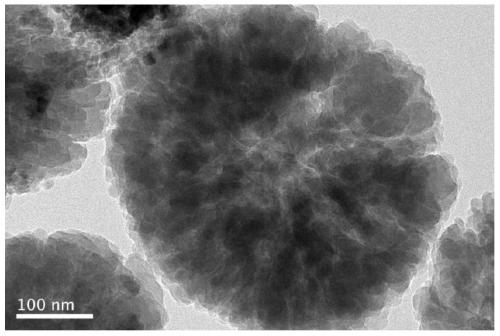

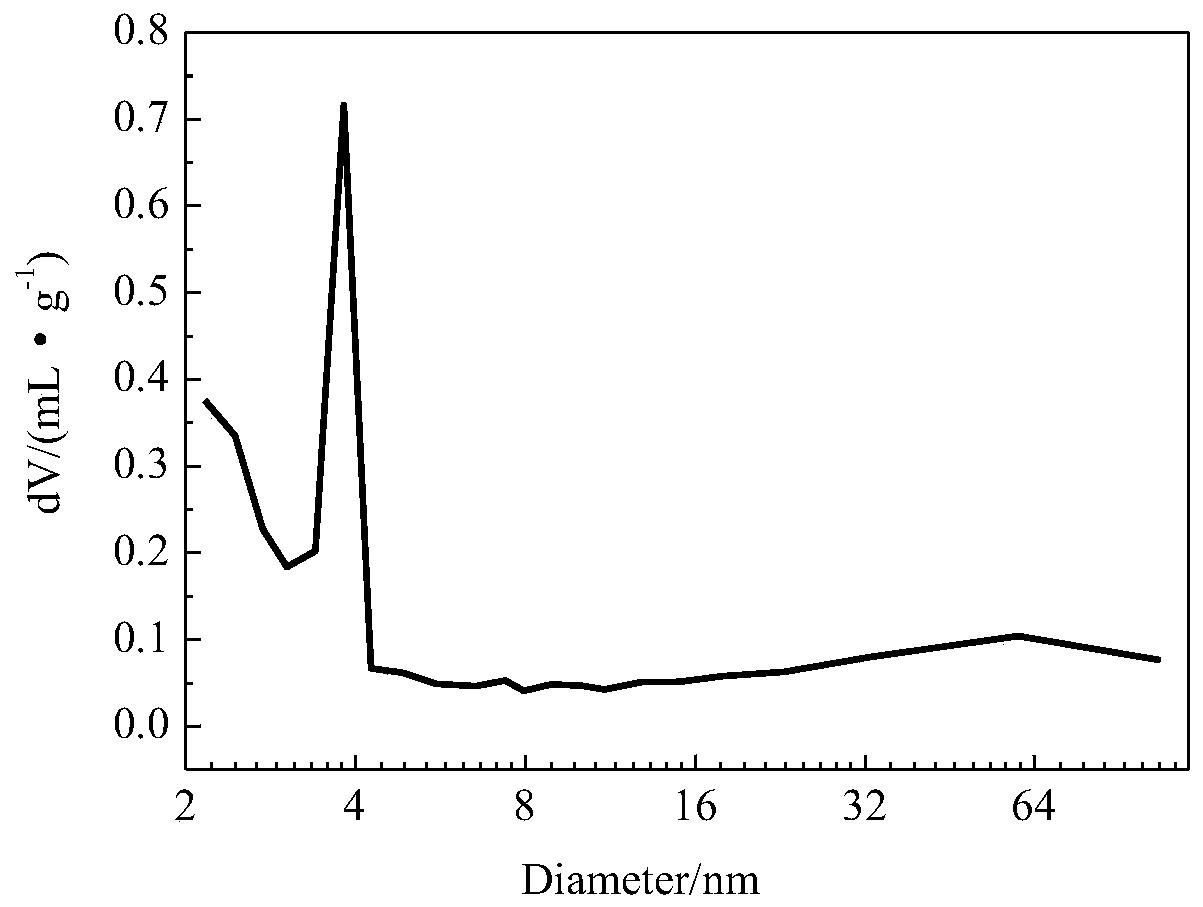

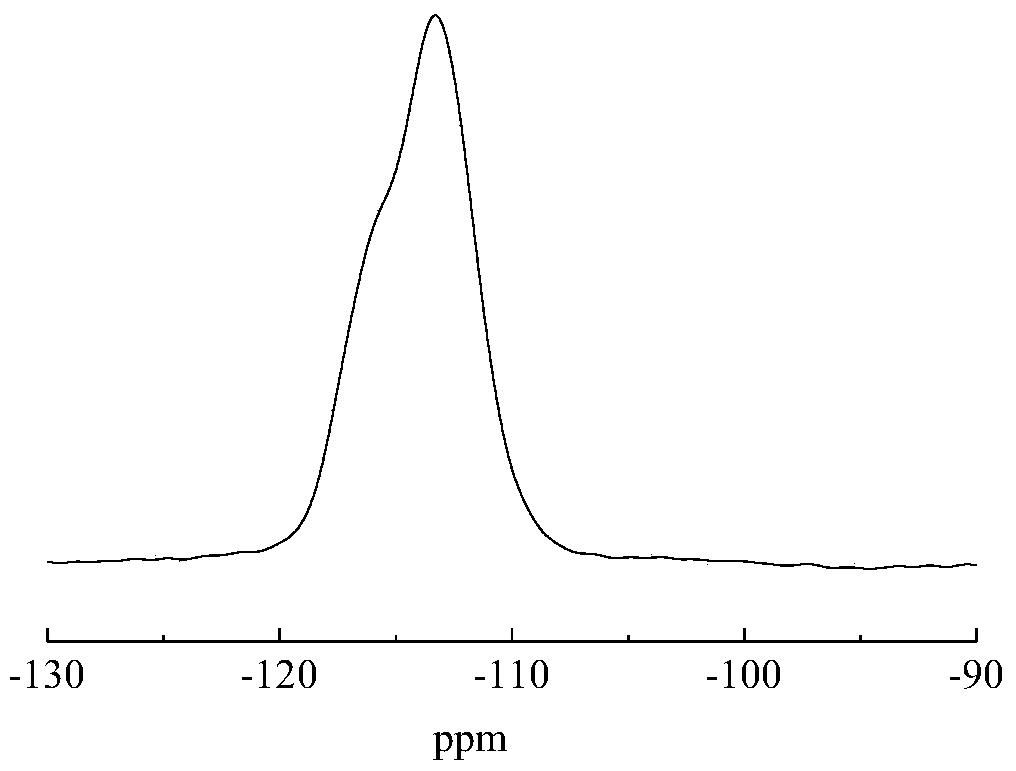

Image

Examples

Embodiment 1

[0077] Under stirring conditions, mix ethyl orthosilicate, tetrapropylammonium hydroxide, tetrabutyl titanate and deionized water to obtain a molar ratio of SiO 2 : Structure directing agent: TiO 2 :H 2 A homogeneous mixture of O=1:0.2:0.025:50; press SiO again 2 : Silylating agent = 1:0.12 molar ratio, add N-phenyl-triaminopropyltrimethoxysilane to the clarified titanium-silicon molecular sieve precursor gel, after stirring evenly, transfer the obtained titanium-silicon molecular sieve precursor To a pressure-resistant stainless steel reactor; under stirring conditions, heated to 170 ° C and crystallized under autogenous pressure for 8h. After the stainless steel pressure-resistant reactor was lowered to room temperature, the titanium-silicon molecular sieve was recovered, dried at 110°C for 6 hours, and then calcined at 550°C for 4 hours to obtain the hierarchically porous titanium-silicon molecular sieve TS-1 prepared by silanization.

[0078] Under stirring conditions, ...

Embodiment 2

[0080] Under stirring conditions, white carbon black, tetrapropylammonium hydroxide, tetraethyl titanate and deionized water were mixed to obtain a molar ratio of SiO 2 : Structure directing agent: TiO 2 :H 2 A homogeneous mixture of O=1:0.5:0.03:100; after pre-crystallization at 90°C for 1, press SiO 2 : Silylating agent = 1:0.2 molar ratio, add hexamethyldisilazane to the titanium-silicon molecular sieve precursor gel obtained by pre-crystallization, stir evenly, transfer the obtained titanium-silicon molecular sieve precursor to a pressure-resistant In a stainless steel reactor; under stirring conditions, heated to 190 ℃ and crystallized under autogenous pressure for 24h. After the stainless steel pressure-resistant reactor was lowered to room temperature, the obtained unroasted titanium-silicon molecular sieve was recovered, dried at 130°C for 4 hours, and then calcined at 550°C for 6 hours to obtain the hierarchically porous titanium-silicon molecular sieve TS- 1.

[...

Embodiment 3

[0083] Under stirring conditions, mix silica gel, tetraethylammonium hydroxide, titanium tetrachloride and deionized water to obtain a molar ratio of SiO 2 : Structure directing agent: TiO 2 :H 2 O=1:1:0.05:150 homogeneous mixture; press SiO again 2 : Silylating agent = 1:0.25 molar ratio, add phenyltriethoxysilane to the clarified titanium-silicon molecular sieve precursor gel, stir evenly, transfer the obtained titanium-silicon molecular sieve precursor to the pressure-resistant stainless steel reaction Kettle; under stirring conditions, heated to 210 ° C and crystallized under autogenous pressure for 12h. After the stainless steel pressure-resistant reactor was lowered to room temperature, the obtained unroasted titanium-silicon molecular sieve was recovered, dried at 150°C for 2 hours, and then calcined at 650°C for 8 hours to obtain the hierarchically porous titanium-silicon molecular sieve TS- 1.

[0084] Under stirring conditions, mix the calcined TS-1, tetrabutylam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com