Preparation method of amino-modified hierarchical porous adsorbent material for cigarette harm reduction

An adsorbent and raw material technology, which is applied in the field of preparation of amino-functionalized hierarchical porous adsorbent materials, can solve the problems of long formation path, decomposition, and inability to directly obtain multi-level materials, etc., and achieves highly connected pore structure and adjustable pore size. , is conducive to the effect of transmission and diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

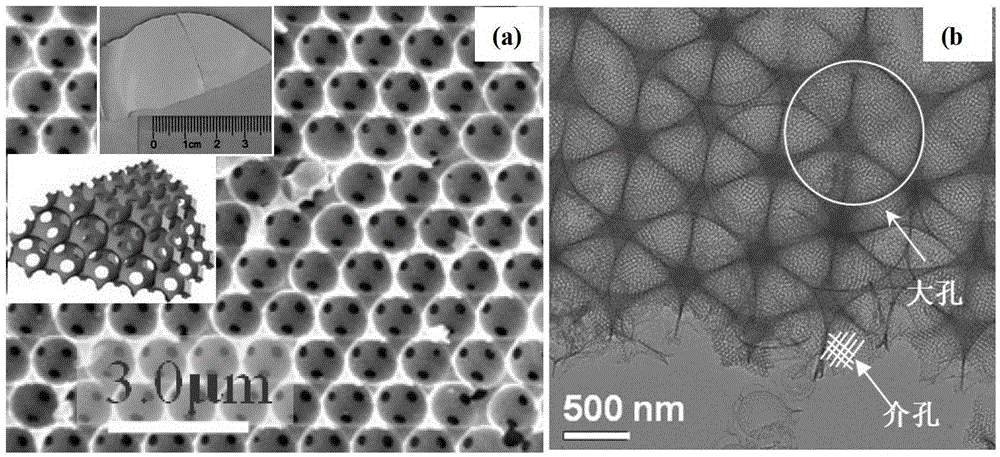

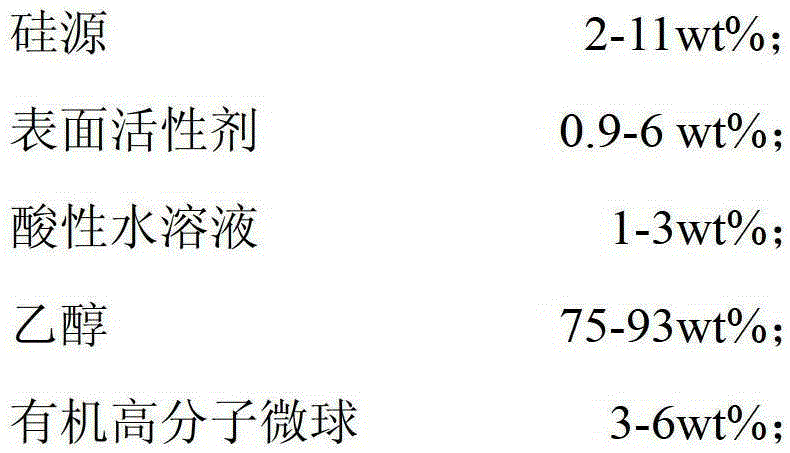

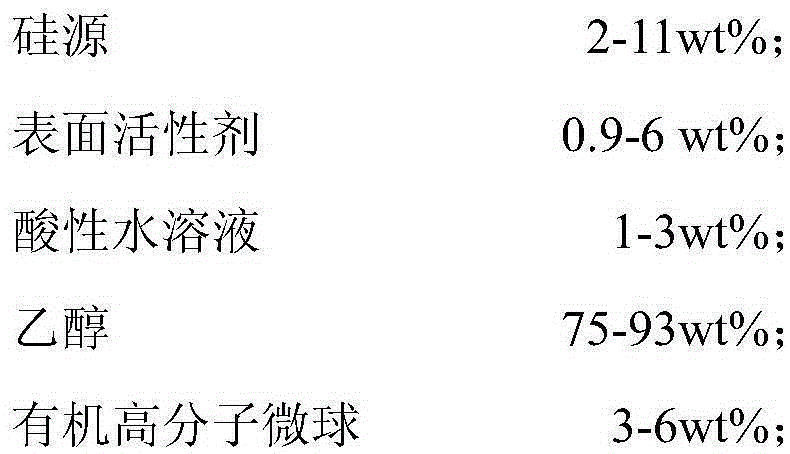

Embodiment 1

[0036] Dissolve 0.25g P123, 0.4g tetraethyl orthosilicate, 0.18g γ-aminopropyltrimethoxysilane and 0.5g hydrochloric acid aqueous solution (2M) in 15g ethanol, and stir at room temperature for 4h, and mix the obtained solution with 10gPMMA The ethanol solution (10%, particle size 220nm) of the balls was mixed evenly by ultrasonic, poured into a petri dish and placed in a 30°C oven to evaporate the solvent. After the solvent evaporated for 24 hours, it was further aged in a 60°C oven for 8 hours to obtain a uniform Composite film. After the film was scraped off, it was slightly crushed and ultrasonically dispersed in tetrahydrofuran (60mL) and refluxed at 50°C for 12h. After the granular product was filtered and washed, it was dried in a vacuum oven at 50°C to obtain a multi-level pore structure. Pore-Mesoporous Silica Adsorbent Materials. The macropore diameter of the material is 200nm, the mesopore diameter is 10.5nm, the specific surface area is 328m2 / g, the pore body is 0....

Embodiment 2

[0038] Dissolve 0.42g of F127, 0.75g of tetraethyl orthosilicate, 0.22g of N-β-aminoethyl-γ-aminopropylmethyldimethoxysilane and 0.8g of aqueous hydrochloric acid (2M) in 10g of ethanol, and Stir at low temperature for 4 hours, and ultrasonically mix the obtained solution with 15g of PS microsphere ethanol solution (10%, particle size 530nm) and then pour it into a petri dish and place it in a 50°C oven to evaporate the solvent. After the solvent evaporates for 18 hours, further Aging treatment in an oven at 80°C for 16 hours to obtain a uniform composite film. After the film was scraped off, it was slightly crushed and ultrasonically dispersed in toluene (100mL) and refluxed at 80°C for 24 hours. After the granular product was filtered and washed, it was dried in a vacuum oven at 50°C to obtain a multi-level pore structure. Pore-Mesoporous Silica Adsorbent Materials. The macropore diameter of the material is 512nm, the mesopore diameter is 12.3nm, the specific surface area i...

Embodiment 3

[0040] Dissolve 0.5g of F108, 1.2g of ethyl orthosilicate, 0.1g of γ-aminopropylmethyldiethoxysilane and 0.4g of aqueous hydrochloric acid (2M) in 10g of ethanol, and stir at room temperature for 12h, and the obtained solution After ultrasonically mixing with 15g of PS microsphere ethanol solution (10%, particle size 1100nm), pour it into a petri dish and put it in a 30°C oven to evaporate the solvent. After the solvent evaporates for 24h, it is further aged in a 60°C oven for 24h. A uniform composite film is obtained. After the film is scraped off, it is slightly crushed and ultrasonically dispersed in dichloromethane (100mL) and refluxed at 60°C for 12h. After the granular product is filtered and washed, it is dried in a vacuum oven at 50°C to obtain a multi-level pore structure. , Macroporous-mesoporous silica adsorbent material. The macropore diameter of the material is 1055nm, the mesopore diameter is 8.0nm, the specific surface area is 408m2 / g, the pore body is 0.51cm3 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com