Aluminizer adhesive layer resin containing graphene oxide and preparation method thereof

A technology of anodized aluminum foil and acrylic resin, applied in the direction of adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., to achieve the effects of improving ironing performance, high specific surface area, and easy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

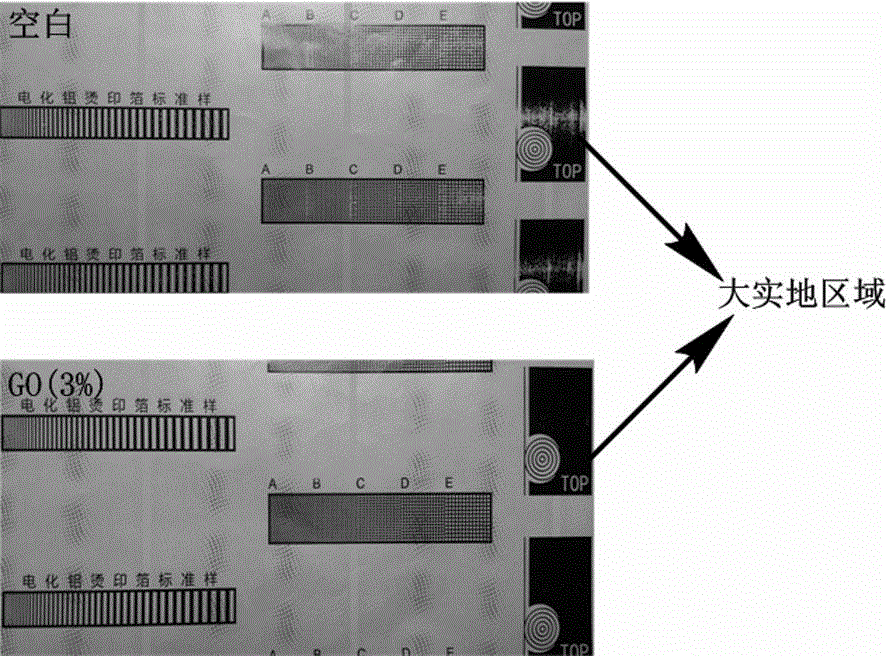

Image

Examples

Embodiment 1

[0040] Put 5.0 kg of n-butanol into the reaction kettle, and control the temperature in the kettle to 30°C; add 3kg of hydroxyethyl methacrylate and 0.6kg of nitrocellulose in sequence, stir for 3 hours, and control the temperature during the entire batching process to 30°C. ℃, the stirring rate is 300 r / min; add 1.02 kg silicon powder, 300 g GO, and 80 g glyceride into the kettle at one time, and stir for 4 hours; the uniformly mixed materials flow into the storage tank through the kettle body device for later use.

Embodiment 2

[0042]Put 6.05kg of n-butanol into the reaction kettle, control the temperature in the kettle to 25°C; add 2.5kg of hydroxyethyl methacrylate and 0.5kg of nitrocellulose in sequence, control the stirring speed between 200 r / min, and stir 2 h; add 0.8kg of silicon powder, 0.1kg of GO, and 0.05kg of polyethylene wax into the kettle at one time, control the temperature at 25°C, and stir at a stirring rate of 200 r / min for 2 hours; the uniformly mixed materials flow into the storage tank through the kettle body device Standby in the tank, and control the internal temperature to 10°C.

Embodiment 3

[0044] Put 0.5 kg of n-butanol into the reaction kettle, control the temperature in the kettle to 60°C; add 4.0 kg of hydroxyethyl methacrylate and 1.5 kg of nitrocellulose in sequence, control the stirring speed between 500 r / min, and stir 4h; Add 2.0 kg of silicon powder, 1.0 kg of GO, and 1.0kg of polyacrylic acid into the kettle at one time, control the temperature at 70°C, stir at a stirring rate of 700 r / min, and stir for 6h; the uniformly mixed materials flow into the storage tank through the kettle body device Standby internally, and control the internal temperature to 35°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com