Compound immobilized enzyme carrier material and preparation method and application thereof

A technology for immobilizing enzyme carriers and carrier materials, which is applied in the directions of immobilization on/in organic carriers, biochemical equipment and methods, enzymes, etc. Application, not many functional groups, etc., to achieve the effects of good temperature and storage stability, rich surface functional groups, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

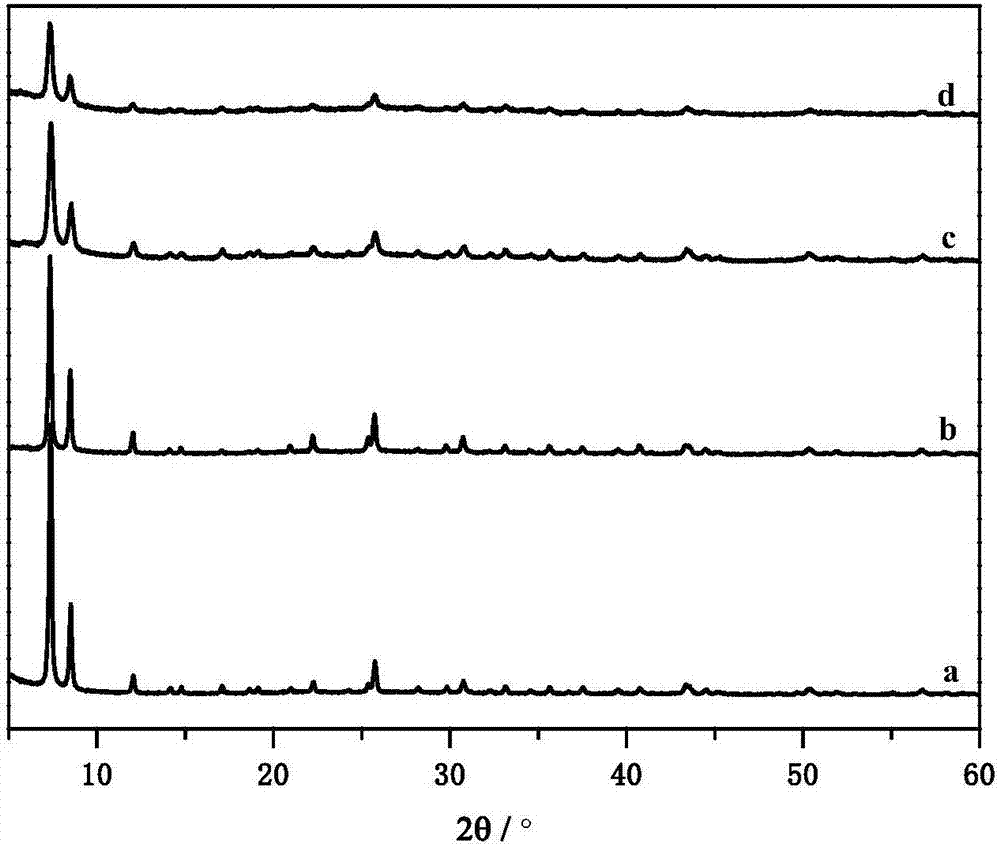

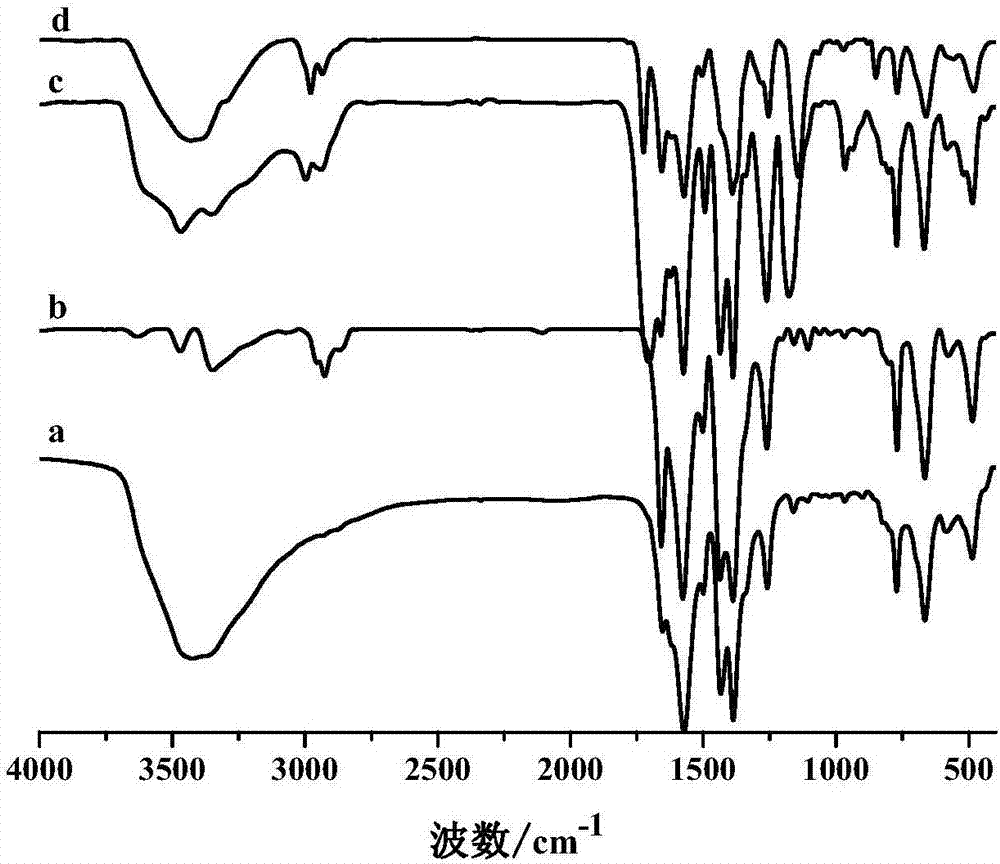

[0034] 1. Add 0.5g (0.285mmol) UiO-66-NH 2 Dissolve the solid in 20mL DMF, add 0.13mL (1.71mmol) 3-bromopropyne and 0.4g (2.91mmol) potassium carbonate, and react at 70°C for 24 hours under a nitrogen atmosphere. and absolute ethanol for 3 times, and vacuum-dried at room temperature to obtain the alkyne-modified UiO-66-NH 2 .

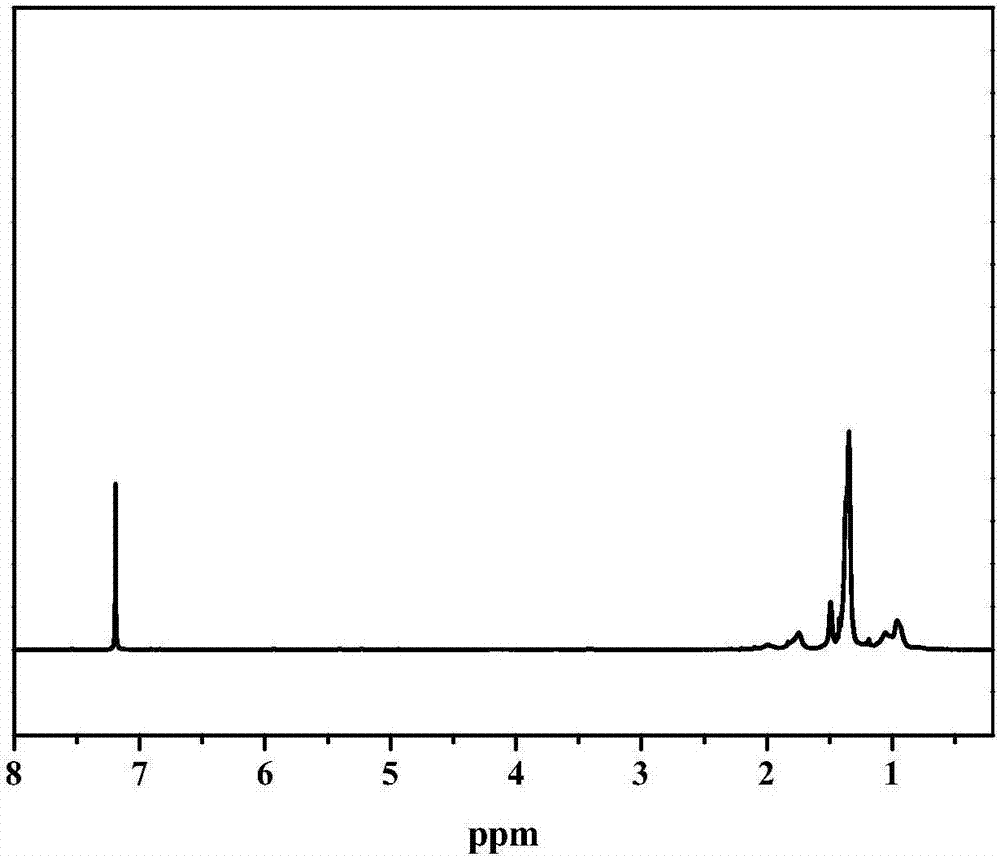

[0035] 2. Dissolve 0.11g (0.5mmol) 2-azidoethyl-2-bromo-methylpropyl ester, 7.1g (50mmol) tBMA and 0.0865g (0.5mmol) PMDETA in 5mL anhydrous methyl ethyl ketone and isopropanol In the mixed solution with a volume ratio of 1:1, add 0.0715g (0.5mmol) CuBr after two consecutive freeze-thaw degassing, freeze-thaw degassing once more, and then react at 60°C under a nitrogen atmosphere for 12 hours. After the reaction, Cool to room temperature, pass through a neutral alumina column after dilution with tetrahydrofuran, and remove most of the solvent from the eluate by a rotary evaporator, then precipitate in a mixed solvent with a volume ratio of methanol an...

Embodiment 2

[0039] The application of the compound immobilized enzyme carrier material of embodiment 1 in immobilizing pectinase, concrete method is as follows:

[0040] Add pectinase to citric acid-disodium hydrogen phosphate buffer solution with a pH value of 4.0 to prepare a 10 U / mL pectinase solution, then add 10 mg of composite immobilized enzyme carrier material to 25 mL of pectinase solution, and keep at room temperature React for 120 minutes, centrifuge at 4000 rpm for 5 minutes, and wash the precipitate with citric acid-disodium hydrogen phosphate buffer solution with pH=4.0 to obtain immobilized pectinase, which is stored at 4°C.

[0041] In order to determine the optimal process condition of the immobilized pectinase of composite immobilized enzyme carrier material of the present invention, inventor has carried out a large amount of laboratory research tests, and concrete test situation is as follows:

[0042] 1. The effect of immobilization time on the activity and adsorption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com