Fire-resistant and wear-resistant coating for circulating fluidized bed boiler and preparation method thereof

A circulating fluidized bed and boiler technology, which is applied in the field of anti-wear coatings, can solve the problems of enterprise production and safety loss, short boiler maintenance period, and various construction equipment, so as to achieve beautiful appearance, improve thermal shock resistance stability and corrosion resistance Sexuality, high binding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A refractory and wear-resistant coating for a circulating fluidized bed boiler, comprising a binder and powder in a weight ratio of 1:0.9,

[0047] The binding agent comprises the following components in parts by weight:

[0048] SiO 2 52 copies

[0049] K 2 O 42 servings

[0050] Na 2 O 5 copies;

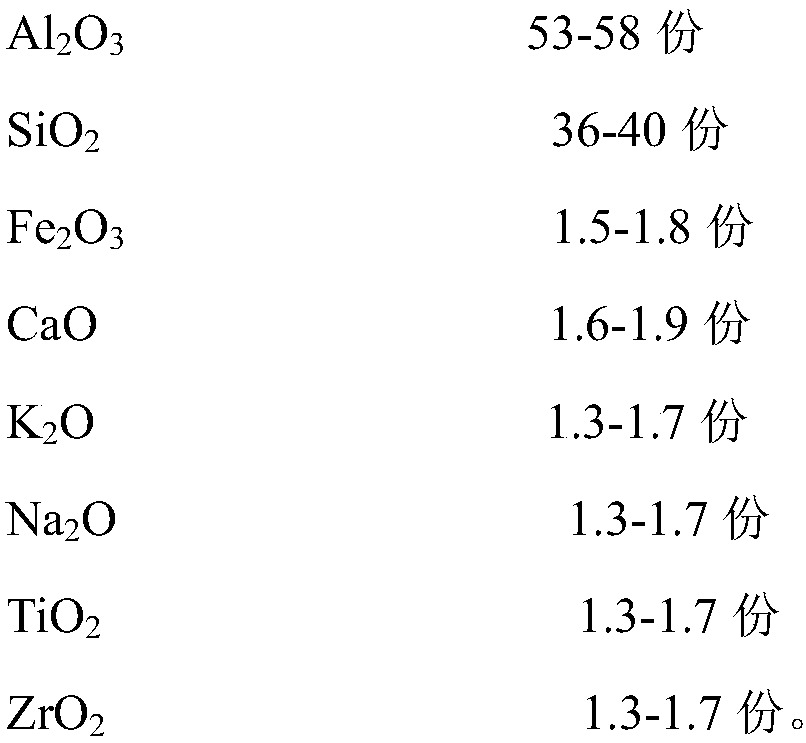

[0051] The powder comprises the following components in parts by weight:

[0052]

[0053] The preparation method comprises the following steps:

[0054] 1. Binder: mix silica sand, caustic potash and caustic soda in a certain proportion and put them into the melting furnace, use heavy oil or electric heating to 1200-1400 °C, when a completely molten transparent body is formed, release it from the furnace to cool and solidify, Then put it into an autoclave, and pass through pressurized steam (0.2MPa) to dissolve. The solution is left to clarify to remove impurities, and the clarified solution is concentrated to obtain the finished product.

[0055] 2. Powder: Pu...

Embodiment 2

[0058] A refractory and wear-resistant coating for a circulating fluidized bed boiler, comprising a binder and a powder in a weight ratio of 1.2:1,

[0059] The binding agent comprises the following components in parts by weight:

[0060] SiO 2 55 copies

[0061] K 2 O 41 copies

[0062] Na 2 O 4.5 parts;

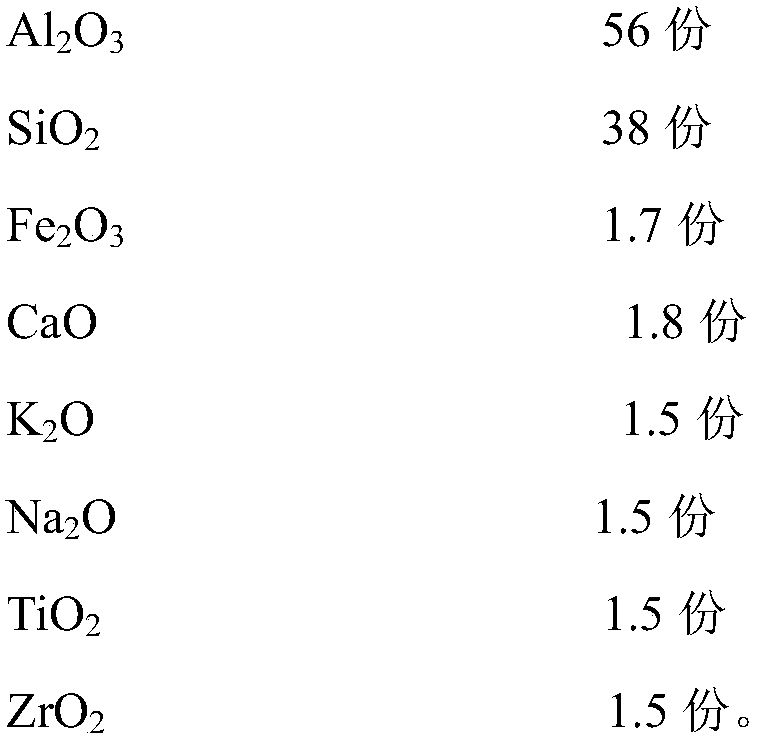

[0063] The powder comprises the following components in parts by weight:

[0064]

[0065] The preparation method comprises the following steps:

[0066] 1. Binder: mix silica sand, caustic potash and caustic soda in a certain proportion and put them into the melting furnace, use heavy oil or electric heating to 1200-1400 °C, when a completely molten transparent body is formed, release it from the furnace to cool and solidify, Then put it into an autoclave, and pass through pressurized steam (0.2MPa) to dissolve. The solution is left to clarify to remove impurities, and the clarified solution is concentrated to obtain the finished product.

[0067] 2. Powder: P...

Embodiment 3

[0070] A refractory and wear-resistant coating for a circulating fluidized bed boiler, including a binder and powder with a weight ratio of 1:0.8,

[0071] The binding agent comprises the following components in parts by weight:

[0072] SiO 2 57 copies

[0073] K 2 O 40 servings

[0074] Na 2 O 4.0 copies;

[0075] The powder comprises the following components in parts by weight:

[0076]

[0077] The preparation method comprises the following steps:

[0078] 1. Binder: mix silica sand, caustic potash and caustic soda in a certain proportion and put them into the melting furnace, use heavy oil or electric heating to 1200-1400 °C, when a completely molten transparent body is formed, release it from the furnace to cool and solidify, Then put it into an autoclave, and pass through pressurized steam (0.2MPa) to dissolve. The solution is left to clarify to remove impurities, and the clarified solution is concentrated to obtain the finished product.

[0079] 2. Powder:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com