Method for manufacturing radiation shield composite material for 3D printing

A 3D printing and radiation shielding technology, applied in the field of manufacturing, can solve the problems of shielding products that cannot do what they want, hidden dangers in life, and the inability to tailor-made shielding products, so as to achieve a more perfect and reasonable shielding structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

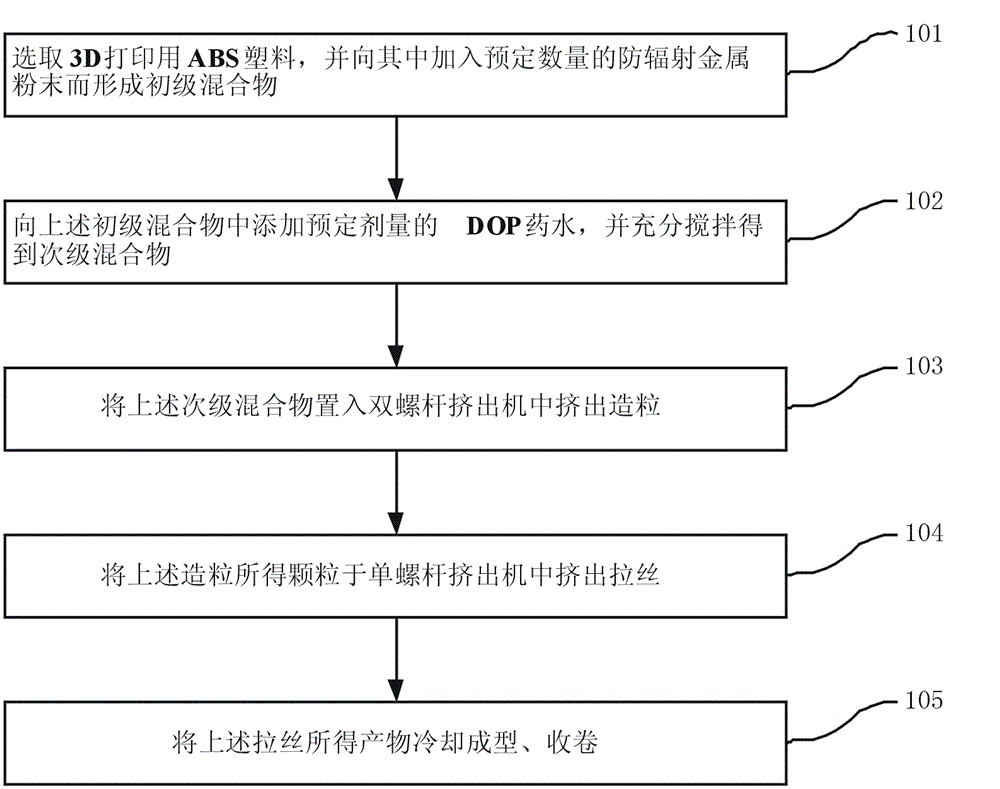

[0021] Such as figure 1 Shown, the method for the radiation shielding composite material that manufactures 3D printing of the present invention, comprises the steps:

[0022] Step 101, select ABS plastic for 3D printing, and add a predetermined amount of anti-radiation metal powder into it to form a primary mixture.

[0023] In this step, ABS (Acrylonitrile Butadiene Styrene plastic, that is, acrylonitrile-butadiene-styrene plastic) plastic is selected as the material, and a predetermined amount of radiation-proof metal powder is added to it. In actual production, the weight ratio of the anti-radiation metal powder to the ABS plastic is 1:4, which can not only ensure the mechanical properties of the composite material processed by ABS plastic as the raw material, but also en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com