Essential oil microcapsule and preparation method thereof

A technology of microcapsule and lemongrass essential oil, applied in microcapsule preparation, microsphere preparation, essential oil/spice and other directions, can solve the problems of uneven particle size distribution, short shelf life, low oil content, etc. The entry of external oxygen, reducing the loss of flavor substances, and the effect of small surface pore area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

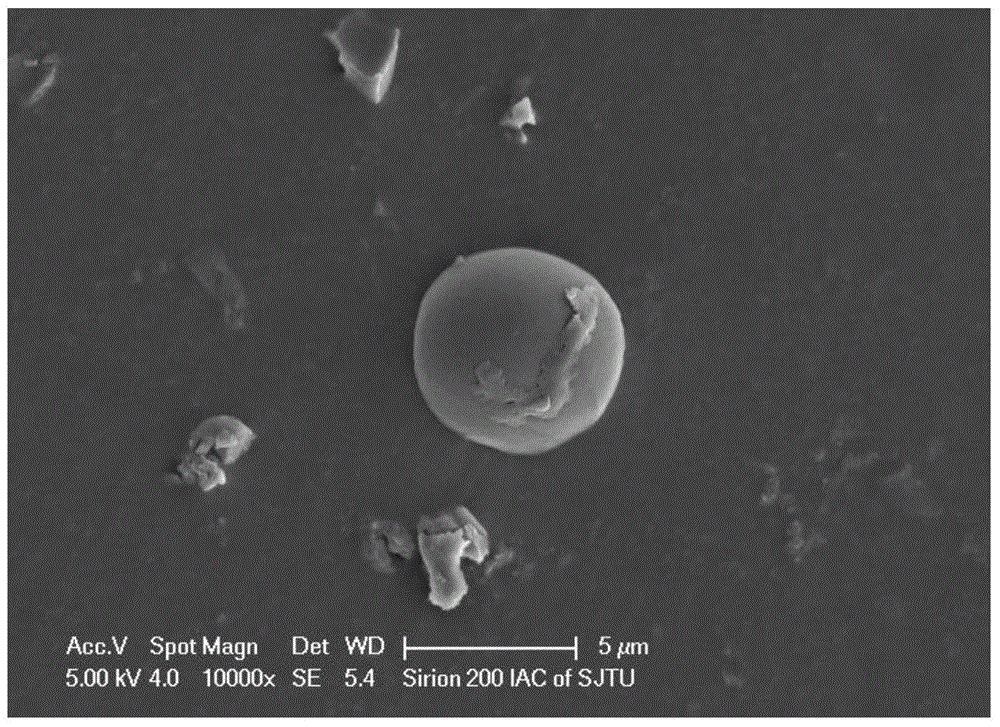

Image

Examples

Embodiment 1

[0041] The present embodiment relates to a kind of lemongrass essential oil microcapsule and preparation method, carry out according to the following steps:

[0042] 1. Determine the type of emulsifier suitable for lemongrass essential oil, which is the composite use of monoglyceride and sucrose ester, and the parts by weight in the lemongrass essential oil microcapsules are respectively 0.278 and 2.847; the weight percentages in the emulsifier are respectively 26.8%, 73.2%, the HLB value of the emulsification system, that is, the water-oil balance value is 12;

[0043] 2. Prepare the saturated aqueous solution of the wall material, stir evenly at a low speed of 150rpm, slowly add the emulsifier, after all the emulsifier is added, add the corresponding parts by weight of lemongrass at a speed of 60 drops per minute under stirring The essential oil is added to form a mixed system, including the following components in parts by weight: 12.5 parts of lemongrass essential oil, 50 ...

Embodiment 2

[0048] The present embodiment relates to a kind of lemongrass essential oil microcapsule and preparation method, carry out according to the following steps:

[0049] 1. Determine the type of emulsifier suitable for lemongrass essential oil, which is the composite use of monoglyceride and sucrose ester, and the parts by weight in the lemongrass essential oil microcapsules are respectively 0.278 and 2.847; the weight percentages in the emulsifier are respectively 26.8%, 73.2%, the HLB value of the emulsification system, that is, the water-oil balance value is 12;

[0050] 2. Prepare the saturated aqueous solution of the wall material, stir evenly at a low speed of 150rpm, slowly add the emulsifier, after all the emulsifier is added, add the corresponding parts by weight of lemongrass at a speed of 60 drops per minute under stirring essential oil) to form a mixed system, comprising the following components in parts by weight: 12.5 parts of lemongrass essential oil, 100 parts of w...

Embodiment 3

[0055] The present embodiment relates to a kind of lemongrass essential oil microcapsule and preparation method, carry out according to the following steps:

[0056] 1. Determine the type of emulsifier suitable for lemongrass essential oil, which is the composite use of monoglyceride and sucrose ester, and the parts by weight in the lemongrass essential oil microcapsules are respectively 0.278 and 2.847; the weight percentages in the emulsifier are respectively 26.8%, 73.2%, the HLB value of the emulsification system, that is, the water-oil balance value is 12;

[0057] 2. Prepare the saturated aqueous solution of the wall material, stir evenly at a low speed of 150rpm, slowly add the emulsifier, after all the emulsifier is added, add the corresponding parts by weight of lemongrass at a speed of 60 drops per minute under stirring essential oil) to form a mixed system, comprising the following components in parts by weight: 100 parts of lemongrass essential oil, 50 parts of wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com