One-step electro-synthesis method of iron-layered double hydroxide nanosheet array

A technology of nanosheet array and hydrotalcite, which is applied in the direction of nanotechnology, electrolytic inorganic material coating, etc., can solve the problems of harsh equipment requirements and serious energy consumption, and achieve the effect of broadening the application field and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

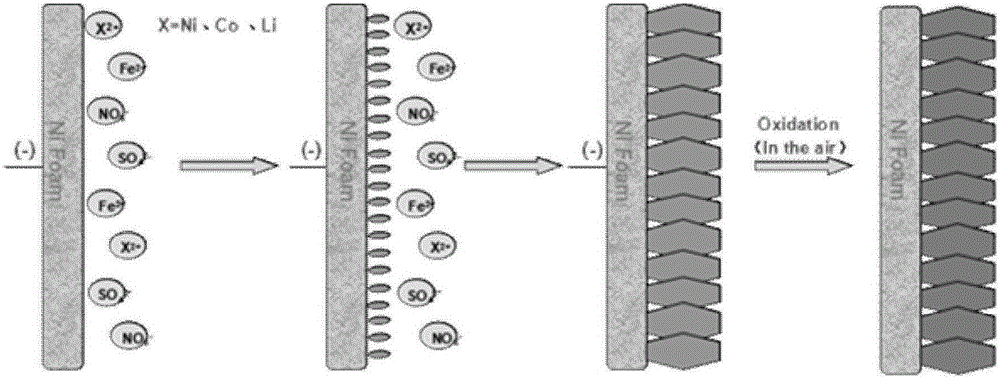

Method used

Image

Examples

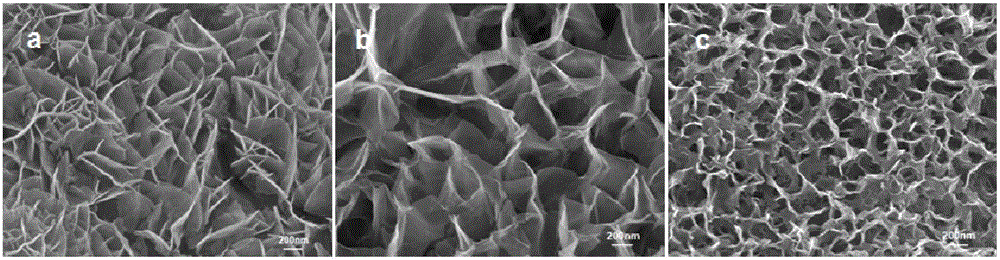

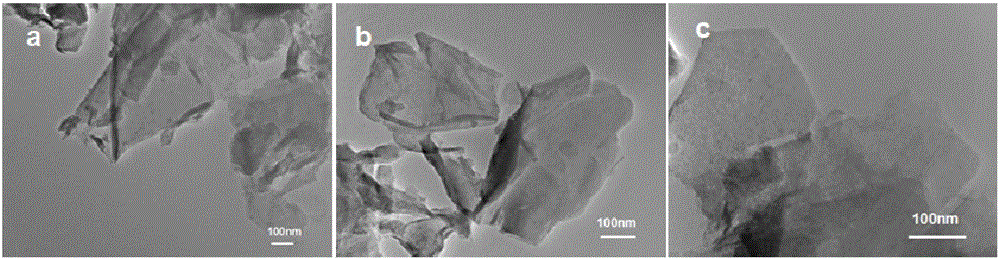

Embodiment 1

[0018] Synthesis of nickel-iron hydrotalcite nanosheet arrays supported on foamed nickel:

[0019] a: the nickel foam of the conductive base is respectively ultrasonicated for 10 min with dehydrated alcohol, acetone and deionized water to remove impurities on the surface;

[0020] b: Prepare 1mg / mL nickel nitrate (Ni(NO 3 ) 2 ), 0.5mg / mL ferrous sulfate (FeSO 4 ) of mixed salt solution 50mL as the electrolyte solution;

[0021] c: In the electrolyte solution prepared in step a, a saturated calomel electrode is used as a reference electrode, and a platinum wire is used as a counter electrode, and a nickel-iron hydrotalcite nanosheet array is directly grown on foamed nickel by a constant potential method, and the electrochemically synthesized potential is set -0.9V, the synthesis time is 200s, and the synthesis temperature is 25°C.

Embodiment 2

[0023] Synthesis of cobalt-iron hydrotalcite nanosheet arrays:

[0024] a: the nickel foam of the conductive base is respectively ultrasonicated for 10 min with dehydrated alcohol, acetone and deionized water to remove impurities on the surface;

[0025] b: prepare 0.5mg / mL cobalt nitrate (Co(NO 3 ) 2 ), 0.25mg / mL ferrous sulfate (FeSO 4 ) of mixed salt solution 50mL as the electrolyte solution;

[0026] c: In the electrolyte solution prepared in step a, the saturated calomel electrode is used as the reference electrode, and the platinum wire is used as the counter electrode, and the cobalt-iron hydrotalcite nanosheet array is directly grown on the nickel foam by the constant potential method, and the electrochemically synthesized potential is set is -1V, the synthesis time is 400s, and the synthesis temperature is 25°C.

Embodiment 3

[0028] Synthesis of Lithium Iron Hydrotalcite Nanosheet Arrays:

[0029] a: the nickel foam of the conductive base is respectively ultrasonicated for 10 min with dehydrated alcohol, acetone and deionized water to remove impurities on the surface;

[0030] b: Prepare 0.5mg / mL lithium nitrate (LiNO 3 ), 0.25mg / mL ferrous sulfate (FeSO 4 ) of mixed salt solution 50mL as the electrolyte solution;

[0031] c: In the electrolyte solution prepared in step a, the saturated calomel electrode is used as the reference electrode, the platinum wire is used as the counter electrode, and the lithium-iron hydrotalcite nanosheet array is directly grown on the nickel foam by the constant potential method, and the electrochemically synthesized potential is set is -1.1V, the synthesis time is 300s, and the synthesis temperature is 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com