Exhaust gas recirculation system and automobile

A technology of recirculation system and exhaust gas recirculation valve, which is applied in the charging system, fuel air inlet, and adding non-fuel substances to fuel, etc., which can solve the problem of performance degradation of supercharged gasoline engines, poor control accuracy, and EGR rate of EGR system No high problems, to achieve the effect of reducing emissions, improving fuel economy, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

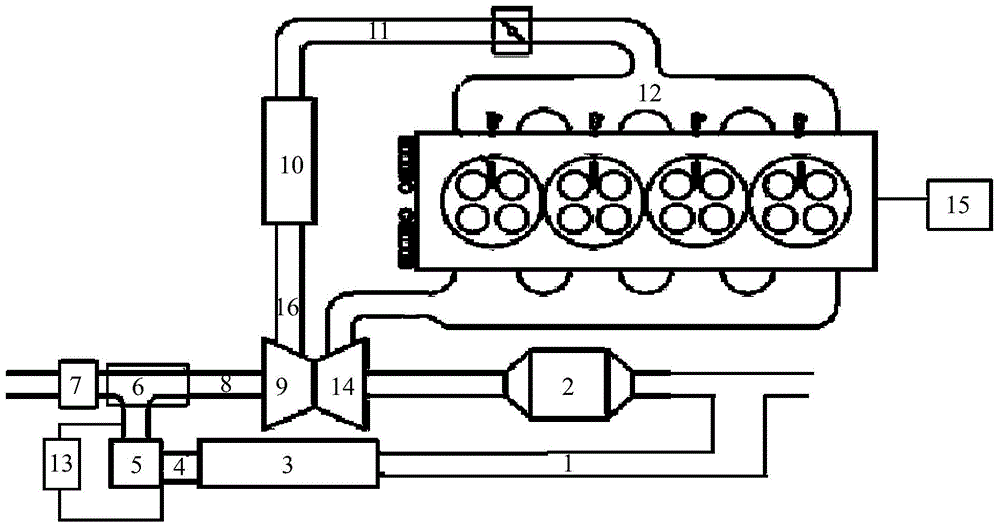

[0024] refer to figure 1 As shown, the present invention provides an exhaust gas recirculation system, comprising: a front-stage catalyst 2, which receives the exhaust gas discharged from the turbine 14; Exhaust gas; exhaust gas recirculation valve 5, connected to cooler 3; throttle body 7 for assisting the establishment of EGR pressure difference, external air is passed into the system through this throttle body 7; premixing pressure chamber 6, respectively Connected with the exhaust gas recirculation valve 5 and the throttle body 7, the exhaust gas entering the premixing pressure chamber 6 from the exhaust gas recirculation valve 5 and the external air entering the premixing pressure chamber 6 from the throttle body 7 are separated into the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com