Novel thermogravimetric analysis device

A new type of thermogravimetric analysis technology, applied in the field of material thermal analysis, can solve the problems of not representing the actual temperature of the sample, unable to meet the thermal analysis test, increasing heat transfer resistance, etc., to achieve the effect of reliable thermogravimetric analysis data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiments and drawings.

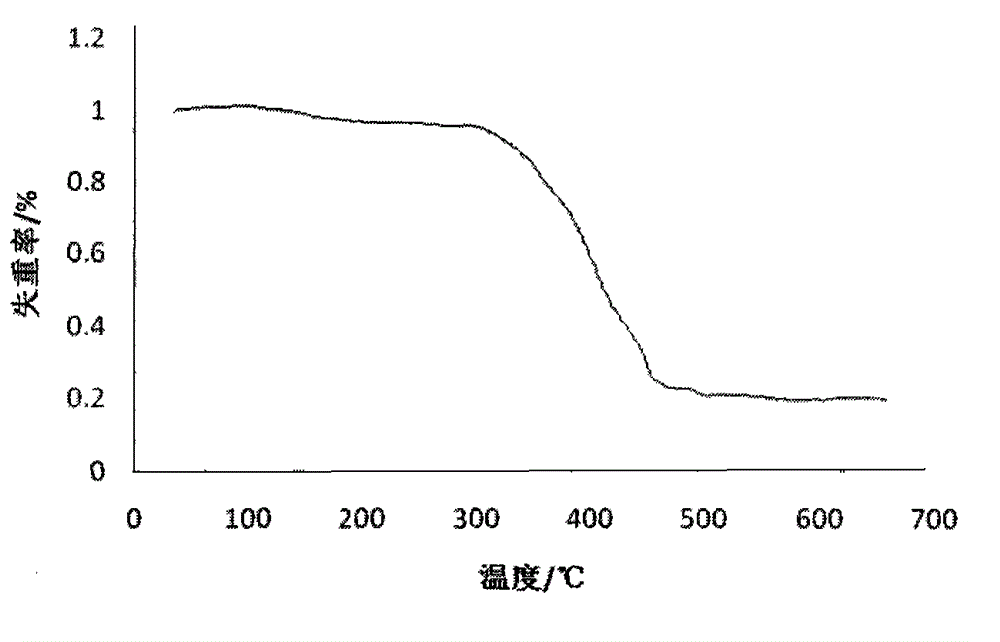

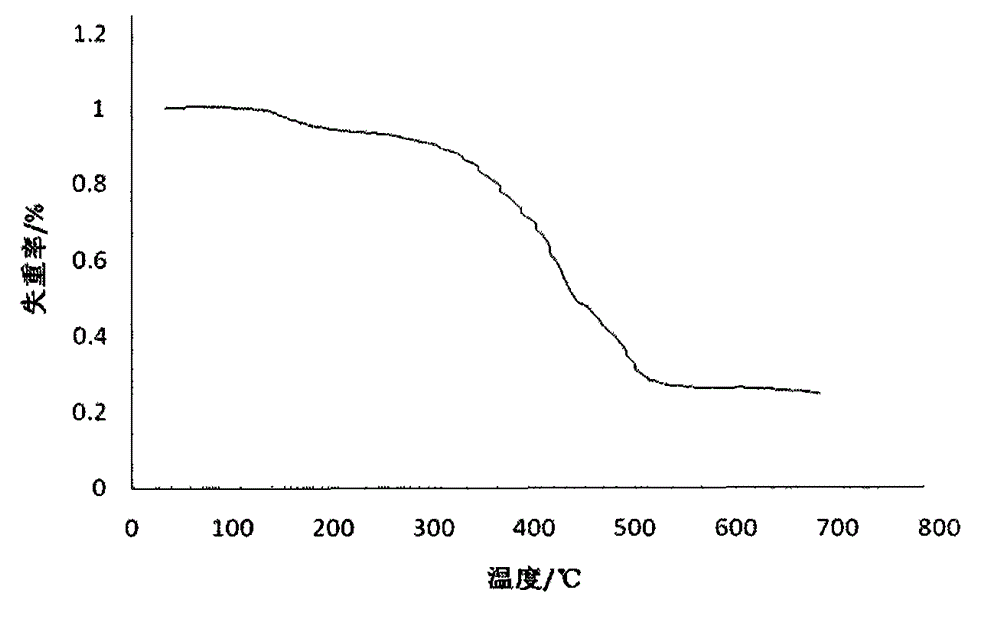

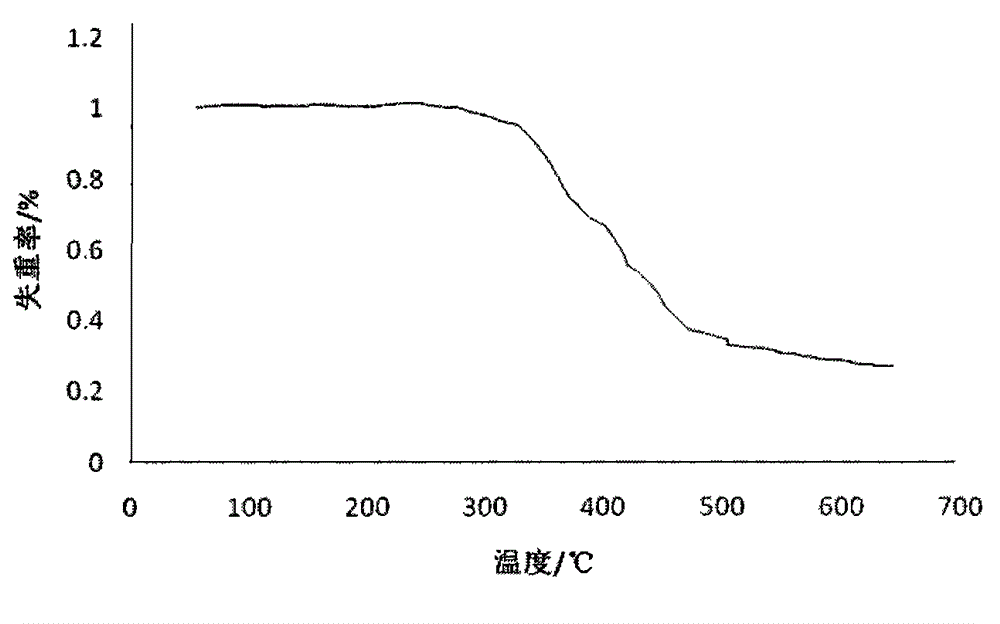

[0020] figure 1 Is a schematic diagram of the new thermogravimetric analysis device of the present invention, figure 2 It is a schematic diagram of the single-sided heating of the sample. One side of the sample 22 is the heating element 2, and the other side is the insulation element 19. The outer temperature sensor 20 is placed between the heating element 2 and the sample 22, and the inner temperature sensor 21 is placed on the insulation element. Between 19 and sample 22, image 3 It is a schematic diagram of heating on both sides of the sample. Two Chinese fir samples 22 (length 50mm, width 10mm, thickness 2mm) are stacked between the two heating elements 2, preferably high-temperature alumina ceramic heating sheets, and the external temperature sensor 20 is placed It is used to measure the temperature of the high-temperature alumina ceramic heating piece between the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com