Clamping device for gas inflation type discharge capillary

A clamping device and capillary technology, applied in the direction of electrical components, accelerators, etc., can solve the problems of unstable discharge, short service life, and long time consumption, and achieve easy implementation, good clamping stability, and capillary replacement convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

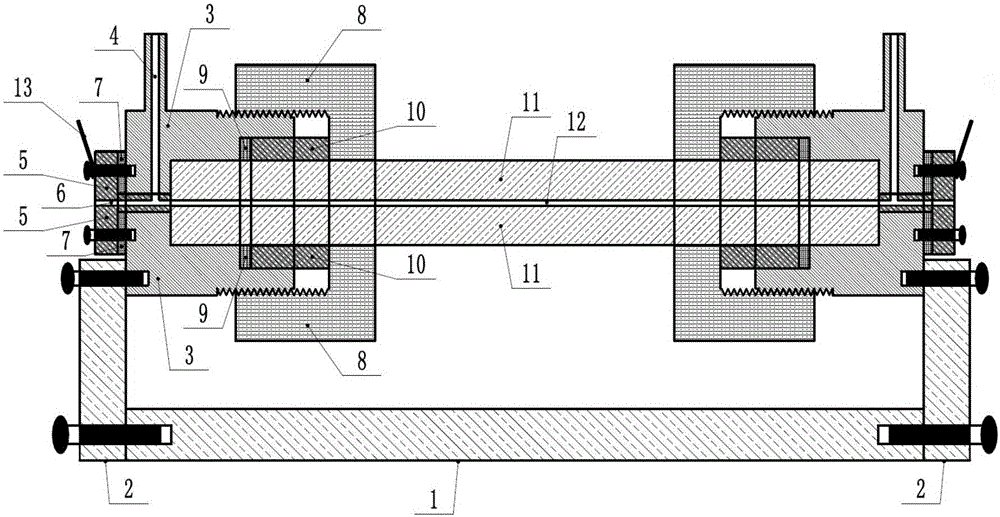

[0031] Such as figure 1 , figure 1 It is a schematic diagram of a clamping device for an inflatable discharge capillary based on the present invention. It can be seen from the figure that the device of the present invention includes: a support base 1, two support frames 2, a clamping sleeve 3, a T-shaped copper electrode 5, a sealing sleeve 8 and an extrusion sleeve 9, and the two support frames 2 are symmetrical fixed on the left and right ends of the support base, the clamping sleeve 3 is fixed on the support frame 2, the copper electrode 5 is embedded on the outside of the clamping sleeve 3, and the center of the copper electrode 5 is provided with an inverted T-shaped There is also a rubber pad 7 between the copper electrode 5 and the clamping sleeve 3, and the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com