Four-drive cooking frying machine and frying pan

A cooking machine and frying pan technology, applied in frying pans, cooking utensils, household heating and other directions, can solve the problems of heat loss, energy waste, oil fume pollution is not environmentally friendly, etc., to avoid energy waste, avoid environmental pollution, and save money. The effect of cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

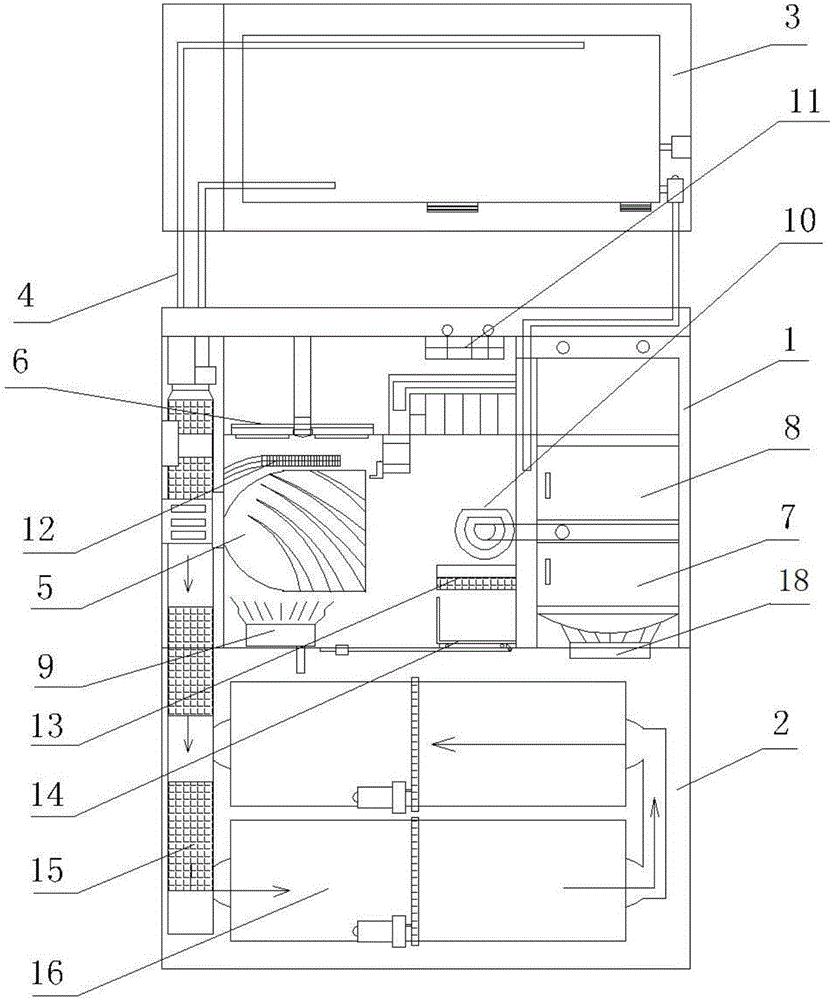

[0055] Such as figure 1 As shown, a four-wheel drive cooking and frying machine is characterized in that it includes: a cooking cavity 1, a heat exchange cavity 2 and an incubator 3, and the high-temperature smoke generated by cooking in the cooking cavity 1 is heat-exchanged by the heat exchange cavity 2 The water exchange pipe is provided in the heat exchange chamber 2, the water inlet end of the water exchange pipe enters cold water, the hot water outlet end of the water exchange pipe is connected to the water inlet pipe 4 of the incubator, and the incubator 3 is used to supply hot water.

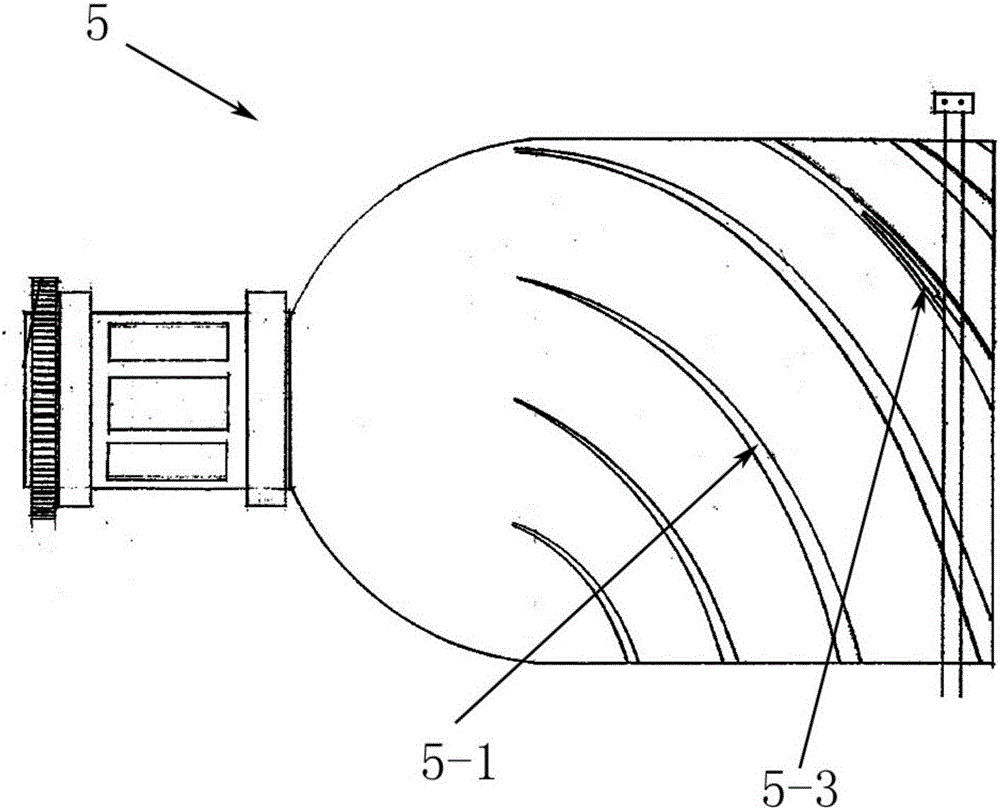

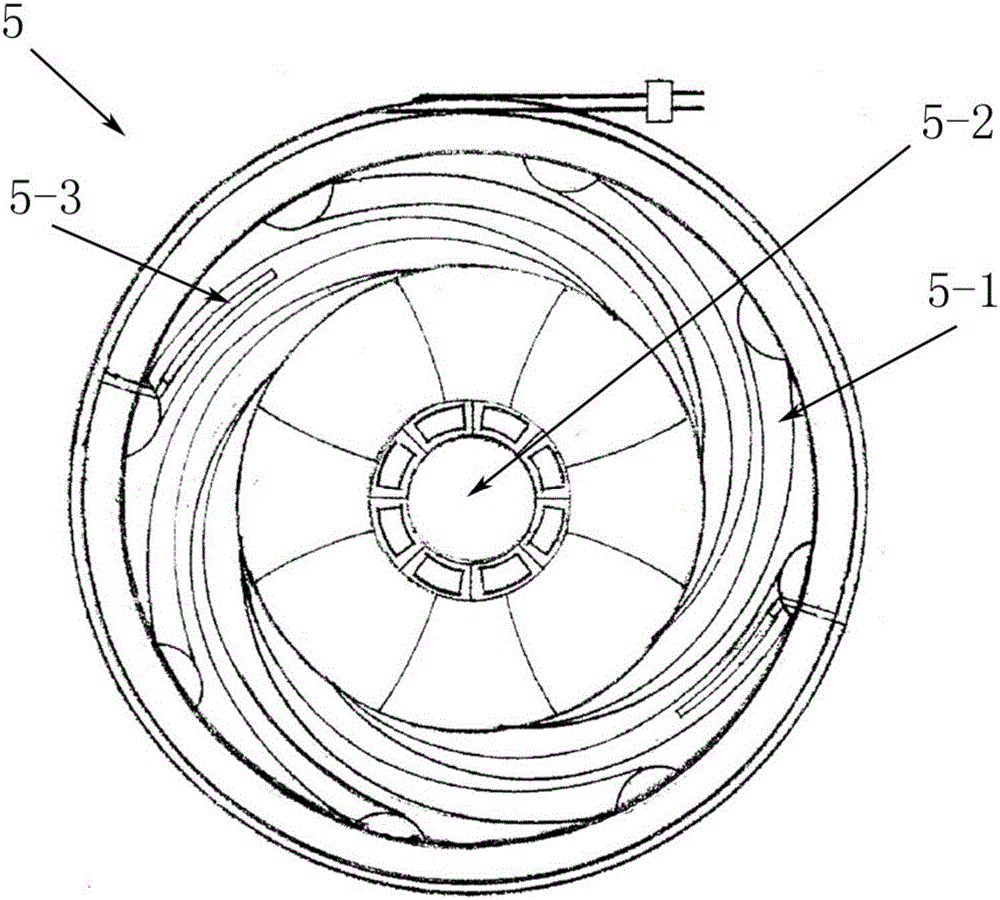

[0056] Wherein, a frying pan 5, a frying pan 6, a steam oven box 7 and an oven oven box 8 are provided in the cooking chamber 1. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com