Horizontal molten compound fertilizer spraying granulation apparatus

A granulation device and compound fertilizer technology, which is applied in the direction of liquid separation into beads and granulation, can solve the problems of high investment, energy consumption and complex structure, and achieve long spraying range, good uniformity, and save the cost of compound fertilizer melting and granulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be further described below:

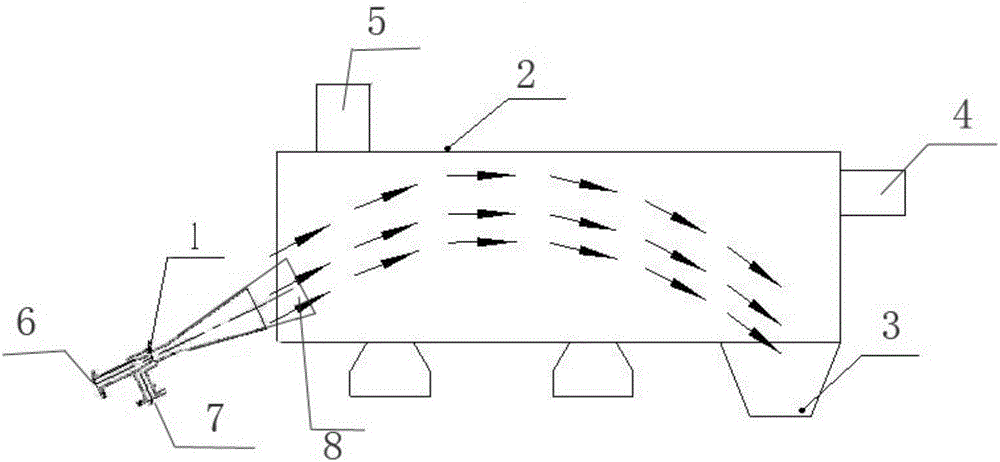

[0021] A horizontal molten compound fertilizer spray granulation device. The spray granulation equipment includes an ejector 1 and a prilling tower 2. The nozzle 8 of the ejector is located on one side of the prilling tower 2, and the nozzle 8 The angle between the upward spray angle of the horizontal plane and the horizontal plane is 30°, the height of the prilling tower is 25m, and the length of the prilling tower is 50m; the height between the nozzle and the bottom of the granulation is 5m; The bottom of the pellet tower is provided with a receiving port 3, which is used to receive fertilizer particles sprayed from the ejector 1, and the length of the receiving port 3 is 0.1 times the length of the prilling tower 2, that is, the receiving material The width is 5m; the number of the receiving opening is 3, and the receiving opening is located at 0m, 10m, 20m from the bottom of the pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com