Iron-tailing anti-blockage water-permeable concrete pavement and preparation method therefor

A technology of permeable concrete and iron tailings, which is applied in the field of building materials, can solve the problems of high resistance to popularization of permeable concrete, decline in mechanical properties, and loss of water-permeable function, and achieve strong innovation and practicability, reduce concrete costs, and broaden the scope of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

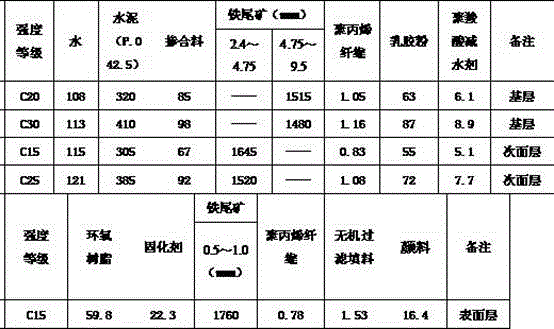

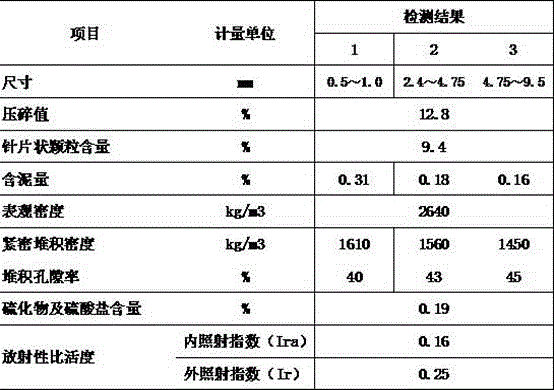

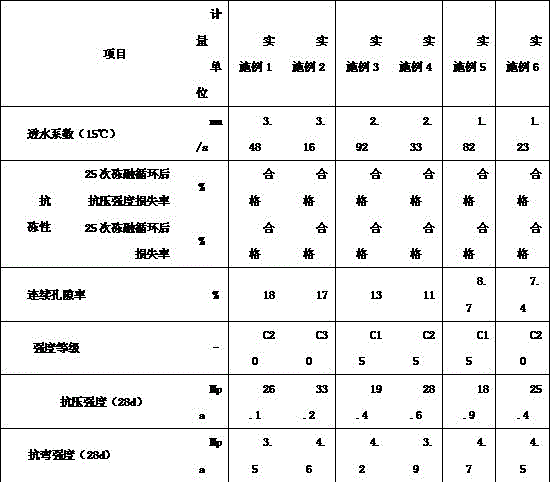

[0023] Embodiment: An iron tailings anti-clogging permeable concrete pavement and its preparation method, the anti-clogging permeable concrete pavement has a three-layer pore structure (base layer, sub-surface layer and surface layer), permeable concrete pavement base layer, sub-surface layer Use No. 52.5 and No. 42.5 Portland cement or ordinary silicon cement as the cementing material, use fly ash, silica fume, slag powder, etc. Plain ether HPMC, latex powder, dispersible rubber powder, etc. are used as modified materials, polypropylene short fiber (PPF) or lignin short fiber is used as reinforcement material, iron tailings are used as aggregate, and polycarboxylic acid superplasticizer is used ; The permeable concrete pavement base layer and the sub-surface layer are mixed in parts by mass: 10-21 parts of cementitious materials, 2-6 parts of blended materials, 2-4 parts of modified materials, 0.03-0.08 parts of reinforcing materials, 62-81 parts of iron tailings, 0.18-0.49 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com