Antibacterial low-temperature ceramic printing ink used for ceramic inkjet printing and a preparing method thereof

A low-temperature ceramic and ceramic inkjet technology, applied in the field of ceramics, can solve the problems of weakened antibacterial stability, easy agglomeration of antibacterial agents, loss of antibacterial effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

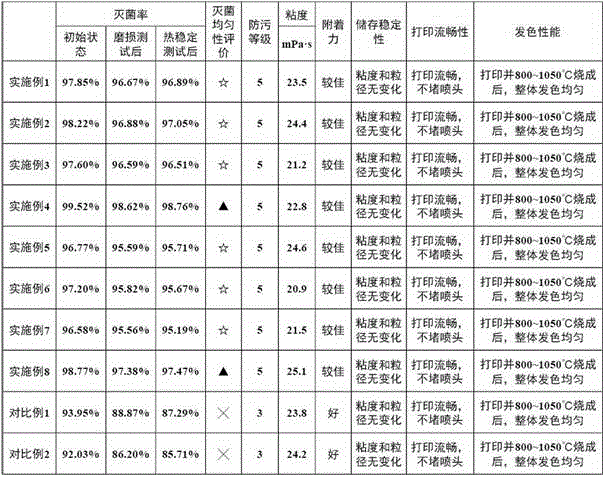

Examples

Embodiment 1

[0037] An antibacterial low-temperature ceramic ink for ceramic inkjet printing and a preparation method thereof, the preparation method comprising the following steps:

[0038] Step A, mix 25% cobalt blue, 4% antibacterial compound, and 20% dry material of low-temperature frit, and then pour it into a fast mixer and mix evenly; use a sand mill for 10 hours to make the particle size distribution ≤ 1 μm;

[0039] Step B. Weigh 5% Tego710, 3.5% AEO-3, 0.2% Levaslip 8629, 0.4% BYK052, 0.8% polystyrene resin, 0.1% Disparlon NS-5501, 41% environmentally friendly hydrocarbon solvent, and then add the Disperse in a high-speed mixer for 30-60 minutes; put the dispersed mixture into a sand mill, and sand it for 10 hours to obtain a semi-finished ink with a particle size distribution of ≤300nm;

[0040] Step C, put the ink semi-finished product obtained in step B in a constant temperature mixing tank at 90°C, then vacuumize, vibrate at a high speed, and filter through a filter screen to...

Embodiment 2

[0051] An antibacterial low-temperature ceramic ink for ceramic inkjet printing and a preparation method thereof, the preparation method comprising the following steps:

[0052] Step A, mix 32% cobalt blue, 2% antibacterial compound, and 18% dry material of low-temperature frit, and then pour it into a fast mixer and mix evenly; use a sand mill for 10 hours to make the particle size distribution ≤ 1 μm;

[0053] Step B. Weigh 5% Tego710, 3.5% AEO-3, 0.2% Levaslip 8629, 0.4% BYK052, 0.8% polystyrene resin, 0.1% Disparlon NS-5501, 38% environmentally friendly hydrocarbon solvent, and then add the Disperse in a high-speed mixer for 30-60 minutes; put the dispersed mixture into a sand mill, and sand it for 10 hours to obtain a semi-finished ink with a particle size distribution of ≤300nm;

[0054] Step C, put the ink semi-finished product obtained in step B in a constant temperature mixing tank at 90°C, then vacuumize, vibrate at a high speed, and filter through a filter screen to...

Embodiment 3

[0065] An antibacterial low-temperature ceramic ink for ceramic inkjet printing and a preparation method thereof, the preparation method comprising the following steps:

[0066] Step A, mix 38% cobalt blue, 0.5% antibacterial compound, and 15% dry material of low-temperature frit, and then pour it into a fast mixer and mix evenly; use a sand mill to grind for 10 hours to make the particle size distribution ≤ 1 μm;

[0067] Step B. Weigh 5% Tego710, 3.5% AEO-3, 0.2% Levaslip 8629, 0.4% BYK052, 0.8% polystyrene resin, 0.1% Disparlon NS-5501, 37% environmentally friendly hydrocarbon solvent, and then add the Disperse in a high-speed mixer for 30-60 minutes; put the dispersed mixture into a sand mill, and sand it for 10 hours to obtain a semi-finished ink with a particle size distribution of ≤300nm;

[0068] Step C, put the ink semi-finished product obtained in step B in a constant temperature mixing tank at 90°C, then vacuumize, vibrate at a high speed, and filter through a filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com