Tubular intelligent energy-saving boiler system

A cross-flow boiler technology, applied in steam boilers, control systems, feed water heaters, etc., can solve the problems of energy waste and low thermal efficiency of boilers, and achieve the effects of strengthening disturbance effects, reducing heat conduction losses, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

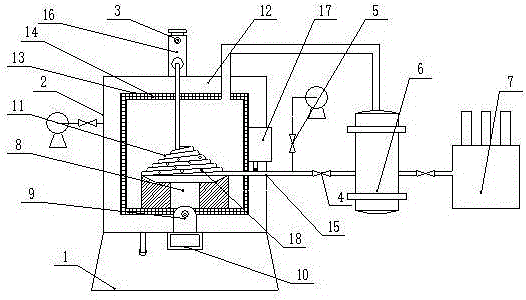

[0025] Embodiment one. Such as figure 1 shown.

[0026] A through-flow intelligent energy-saving boiler system, which includes a base 1, a furnace body 2, a heat exchanger 6, an ion water processor 7, a combustion chamber 8, a burner 9, an intelligent control device 10, a spiral water pipe 11, a gas Water separation device 16 etc., such as figure 1 , the spiral water pipe 11 is installed on the upper part of the combustion chamber 8, and the burner 8 heats the water in the spiral water pipe 11 and then enters the gas-water separation device 16 at the top of the furnace body 2, and the steam generated by the separation of the gas-water separation device 16 passes through the outlet The air port 3 is sent to the gas-consuming equipment, and the condensed water produced by separation returns to the spiral water pipe 11 and is circulated and heated together with the gas-containing water replenished from the water inlet pipe 15. The lower part of the furnace body is provided wit...

Embodiment 2

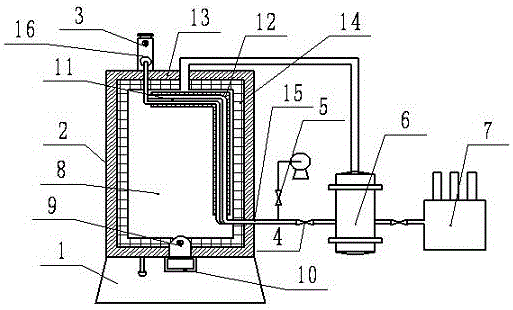

[0029] Such as figure 2 shown.

[0030] A through-flow intelligent energy-saving boiler system, which includes a base 1, a furnace body 2, a heat exchanger 6, an ion water processor 7, a combustion chamber 8, a burner 9, an intelligent control device 10, a tubular water pipe 11, Gas-water separation device 16 etc., such as figure 1 , the top of the body of furnace 2 is provided with a gas-water separator 16, and the steam generated by the gas-water separator 16 is sent to the gas-consuming equipment through the gas outlet 3, and the condensed water generated by the separation returns to the tubular water pipe 11 and is separated from the water inlet pipe. In 15, supplement the gas-containing water that enters and carry out circulation heating together. The lower part of the furnace body is provided with a sewage pipe, the lower end of the furnace body is provided with a burner 9 connected to the combustion chamber 8, and the bottom of the furnace body 2 is provided with a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com