A Coal Gasification Dynamic Simulation System

A technology of dynamic simulation and coal gasification, which is applied in the field of coal chemical industry, can solve problems such as on-site training of operators of pulverized coal gasification equipment, simulation of pulverized coal gasification equipment, etc., to save engineering time, improve success rate, and improve professional quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The application of engineering simulation technology in the process industry, especially in the chemical industry, has been popularized in many developed countries. With the complexity and refinement of the process flow and the continuous development of factory equipment, the technological requirements for the production process are rapidly increasing, and the control requirements are also greatly improved. The requirements are also getting higher and higher. With the gradual development of the application of process system simulation technology, its role has become more and more extensive. At present, the application of simulation technology in the field of process industry has involved education and training, engineering design, auxiliary production and auxiliary research, and its social and economic benefits are becoming more and more significant.

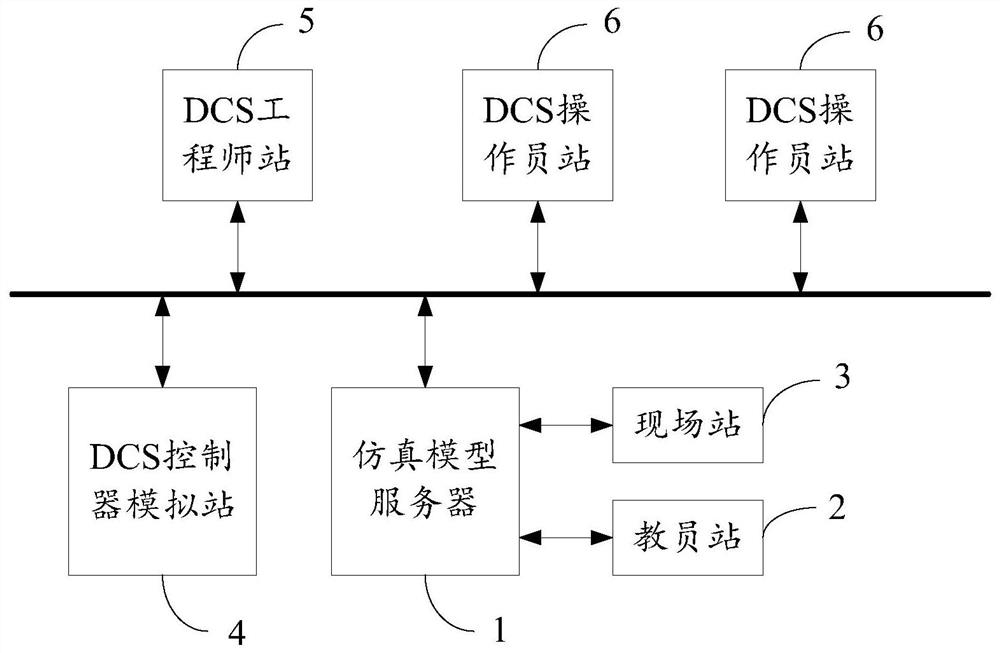

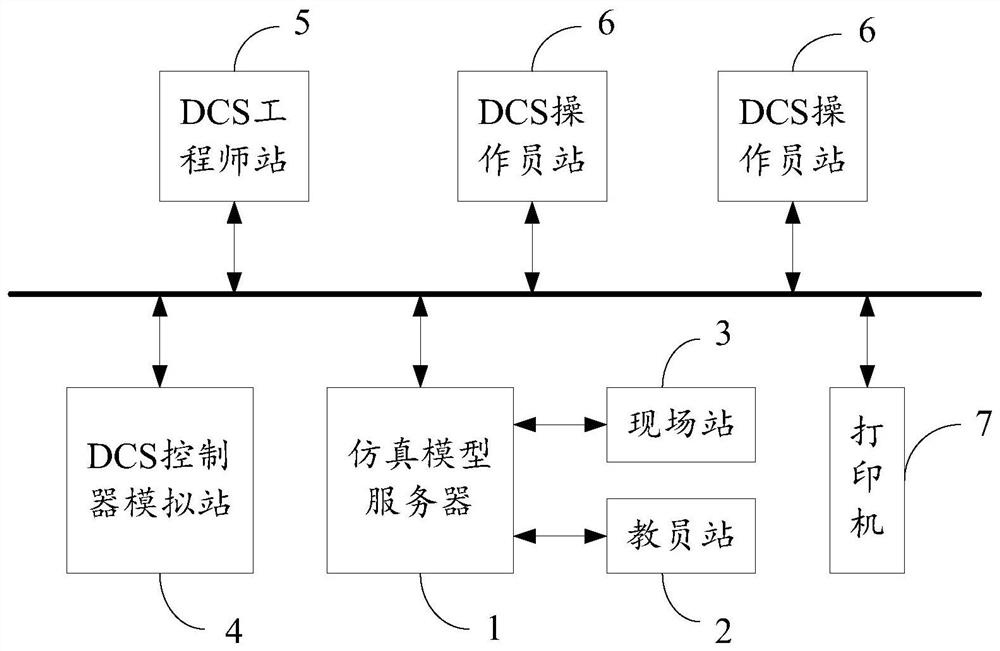

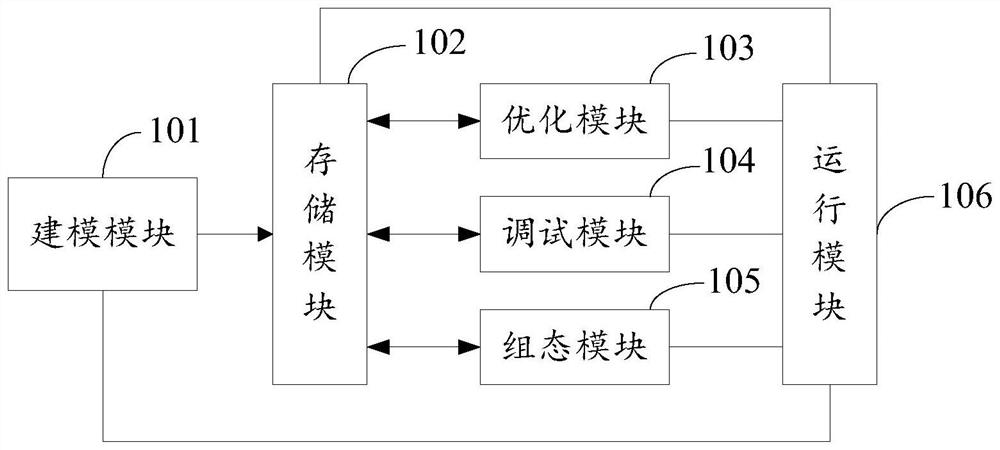

[0049]In order to solve the problems in the prior art that it is impossible to conduct on-site training for operators ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com