Fermentation technology of black tea

A fermentation process and technology of black tea, applied in tea treatment before extraction, etc., can solve problems such as little effect and insufficient quality of black tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

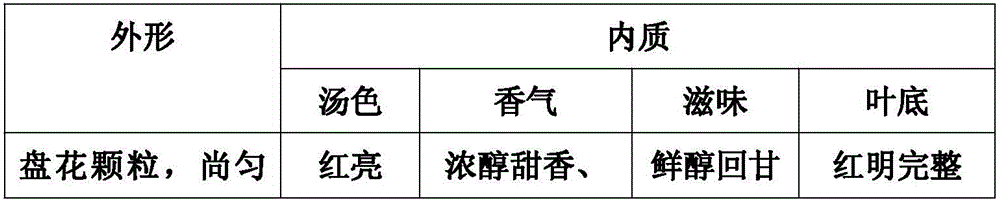

Embodiment 1

[0067] A fermentation process of black tea: select fresh leaves with one bud and one leaf or one bud and two leaves, and carry out withering, rolling and deblocking treatment; feed oxygen into the fermentation room, the oxygen concentration is controlled at 480000ppm, and the temperature in the fermentation room is 25-30 ℃, humidity is 80-90%, according to the mass ratio of rolling leaves and fermented liquid is 100:0.0025, spray the fermented liquid on the rolled leaves, mix well, ferment until there is apple fragrance, take it out, and dry it; the fermented liquid is composed of pectin Mix 10kg of enzyme, 25kg of distiller's grain yellow water, 2kg of lactic acid, 2kg of potassium carbonate, 2kg of sodium carbonate and 55kg of water.

Embodiment 2

[0069] A fermentation process of black tea: select fresh leaves with one bud and one leaf or one bud and two leaves, carry out withering, rolling and deblocking treatment; feed oxygen into the fermentation room, the oxygen concentration is controlled at 500000pp, and the temperature in the fermentation room is 25-30 ℃, humidity is 80-90%, according to the mass ratio of rolling leaves and fermented liquid is 100:0.001, spray the fermented liquid on the rolled leaves, mix well, ferment until there is apple fragrance, take it out, and dry it; the fermented liquid is composed of pectin Mix 20kg of enzyme, 40kg of distiller's grain yellow water, 5kg of lactic acid, 5kg of potassium carbonate, 5kg of sodium carbonate and 65kg of water.

Embodiment 3

[0071]A fermentation process of black tea: select fresh leaves with one bud and one leaf or one bud and two leaves, and carry out withering, rolling and deblocking treatment; feed oxygen into the fermentation room, the oxygen concentration is controlled at 420000ppm, and the temperature in the fermentation room is 25-30 ℃, humidity is 80-90%, according to the mass ratio of rolling leaves and fermented liquid is 100:0.005, spray the fermented liquid on the rolled leaves, mix well, ferment until there is apple fragrance, take it out, and dry it; the fermented liquid is composed of pectin Mix 1kg of enzyme, 10kg of distiller's grain yellow water, 0.5kg of lactic acid, 0.5kg of potassium carbonate, 0.5kg of sodium carbonate and 45kg of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com