Preparation and application of g-C3N4 and polymer PDPB compounded photocatalyst

A polymer, composite light technology, applied in the field of nanomaterials, can solve the problems of small specific surface area, high probability of photo-generated electrons and holes recombination, low photon effective utilization rate, etc., to achieve good catalytic activity, less environmental pollution, and improved light The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] g-C 3 N 4 preparation of

[0028] Add 6g of melamine into a crucible with a lid, place it in a muffle furnace and raise the temperature to 500°C at a rate of 4°C / min, keep it for 2 hours, then raise the temperature to 520°C at a rate of 2°C / min, and keep it for 2 hours. After cooling down to room temperature, it was taken out to obtain a yellow product g-C 3 N 4 , ground into powder for later use.

Embodiment 2

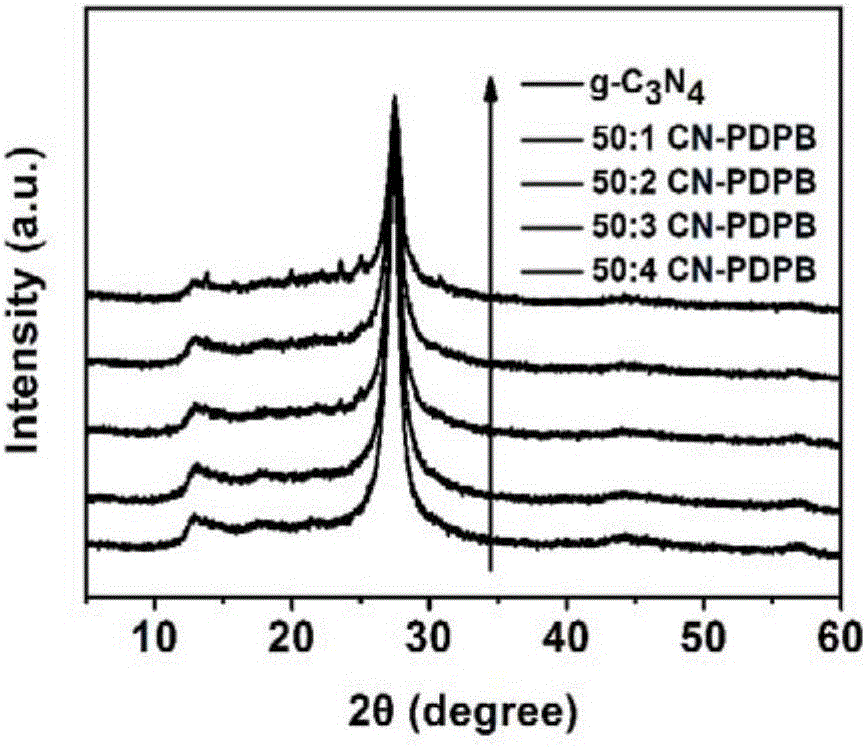

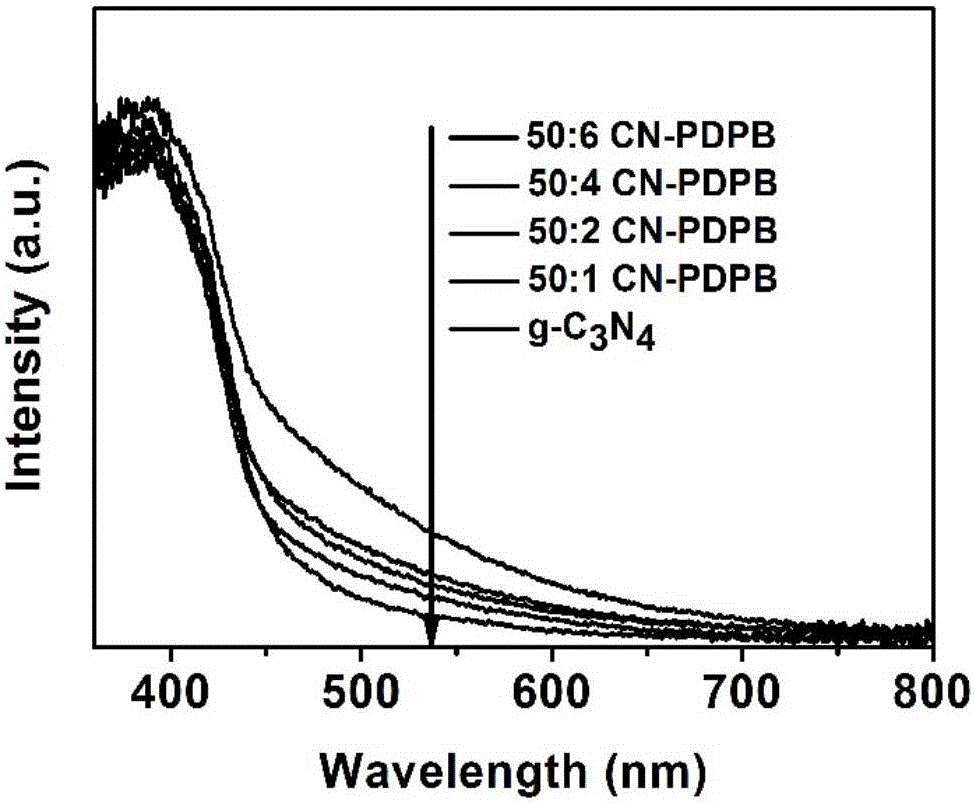

[0030] Preparation of 50:1 CN-PDPB

[0031] Dissolve 10mg PDPB in 10mL ethanol solution, then add 0.5g g-C 3 N 4 Stir for 24h. Then the ethanol solvent was evaporated to dryness in an oil bath, and then placed in an oven at 70°C to dry overnight, cooled naturally to room temperature and ground to obtain a 50:1CN-PDPB material.

Embodiment 3

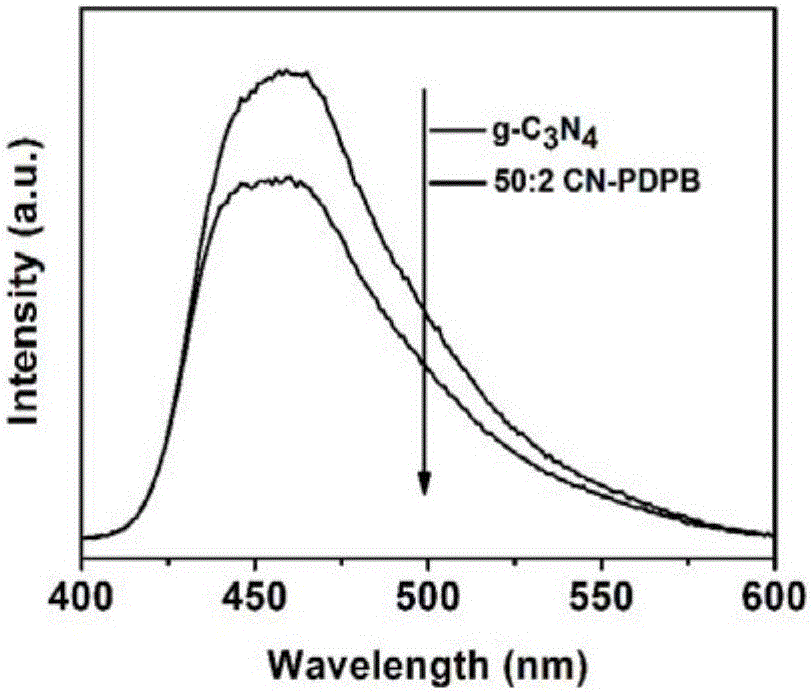

[0033] Preparation of 50:2 CN-PDPB

[0034] Dissolve 20mg PDPB in 10mL ethanol solution, then add 0.5g g-C 3 N 4 Stir for 24h. Then the ethanol solvent was evaporated to dryness in an oil bath, and then placed in an oven at 70°C to dry overnight, cooled naturally to room temperature and ground to obtain a 50:2CN-PDPB material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com