Method for separating blended iron oxide from iron powder

A technology for iron oxide and iron powder, applied in recycling technology, grain processing and other directions, can solve the problems of iron powder and iron oxide, high energy consumption cost, low yield and other problems, and achieve low energy consumption cost and low energy consumption. The effect of production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Production process: Raw materials - first stage screening (removal of particles larger than 0.42 mm and below 0.075 mm) - air separation and crushing system - second stage screening (removal of particles below 0.075 mm) - two-stage dry magnetic separation - Weigh the package.

[0036] Wherein, raw material composition and particle size are as shown in table 1 and table 2:

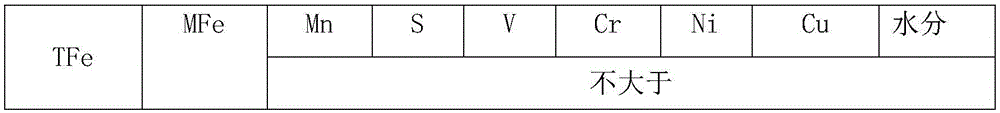

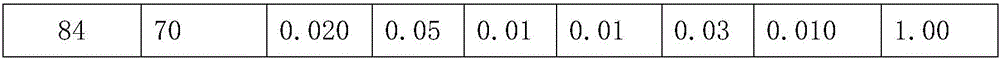

[0037] Table 1 raw material composition (%)

[0038]

[0039]

[0040] Table 2 Raw material particle size composition

[0041] Particle size mm

Proportion%

total%

0.425

0.25

3.76

0.18

3.73

7.49

0.15

6.7

14.19

0.12

16.63

30.82

0.109

5

35.82

0.096

1.53

37.35

0.080

6.2

43.55

0.075

17.2

60.75

Below 0.075

39.25

100

[0042] The first level of screening is used to remove particles beyond the product requirements, that is, particles above 0.42 mm and parti...

Embodiment 2

[0048]Production process: Raw material - first stage screening (remove particles larger than 0.42 mm and below 0.075 mm) - air separation and crushing system - second stage screening (remove particles below 0.075 mm) - two-stage magnetic separation - weighing volume packaging. Wherein, raw material is identical with embodiment 1.

[0049] The first level of screening is used to remove particles below the product requirements, that is, to remove particles and dust larger than 0.42 mm and below 0.075 mm. In order to improve the screening efficiency, an ultrasonic screening machine is used.

[0050] The winnowing and crushing system is used to crush iron oxide, because the pulverizer uses the collision of materials to achieve the crushing effect, and the crushing effect on iron oxide is better, but the crushing effect on iron powder is poor (good toughness, collision cannot crush iron powder). Part of the iron powder particles with a particle size less than 0.075mm can be remov...

Embodiment 3

[0055] Production process: Raw materials - first stage screening (removal of particles above 0.42 mm and below 0.075 mm) - air separation and crushing system - second stage screening (removal of particles below 0.075 mm) - two-stage dry magnetic separation - Weigh the package. Wherein, raw material is identical with embodiment 1.

[0056] The first level of screening is used to remove particles below the product requirements, that is, particles and dust above 0.42 mm and below 0.075 mm. In order to improve the screening efficiency, an ultrasonic screening machine is used.

[0057] The wind separation and crushing system is used to crush iron oxide, because the crushing machine uses the collision of materials to achieve the purpose of crushing, and the crushing effect on iron oxide is better, but the crushing effect on iron powder is poor (good toughness, collision cannot crush iron powder). During the crushing process, the powdered iron oxide adhered to the surface of the ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com