A dry microparticle separation method

A technology of tiny particles and separation methods, applied in solid separation, electrostatic effect separation, chemical instruments and methods, etc., can solve the problems of long processing time, low separation precision, cumbersome operation of dry and wet separation techniques, and achieve operational simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

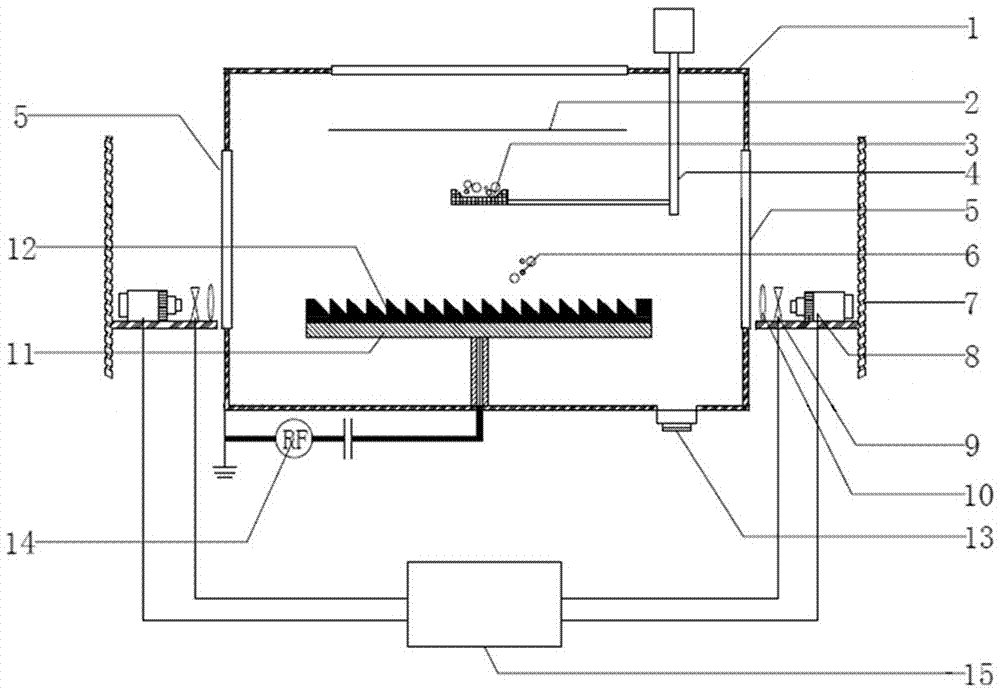

[0030] The dry microparticle separation method provided by the present invention relies on a dry microparticle separation device, such as figure 1 As shown, the dry micro particle separation device includes a vacuum chamber 1, the vacuum chamber 1 is surrounded by a stainless steel cavity, and the stainless steel cavity is grounded; in the vacuum chamber 1, two upper and lower plates are horizontally arranged, which are respectively the upper plate 2 And lower plate 11. In this embodiment, the upper pole plate 2 is composed of two pieces of ITO conductive glass stacked together, and the lower pole plate 11 is a flat metal plate. The upper plate 2 is grounded, the lower plate 11 is connected to the power electrode of the radio frequency power supply 14 , and the other electrode of the radio frequency power supply 14 is grounded. The radio frequency power supply 14 is located outside the vacuum chamber 1 . When the lower plate 11 is connected to the power electrode of the radio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Curvature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com