Anti-damage laser cleaning device

A laser cleaning and anti-damage technology, applied in the field of laser applications, can solve the problem that the surface of the substrate is easily damaged by laser burning, and achieve the effect of uniform light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

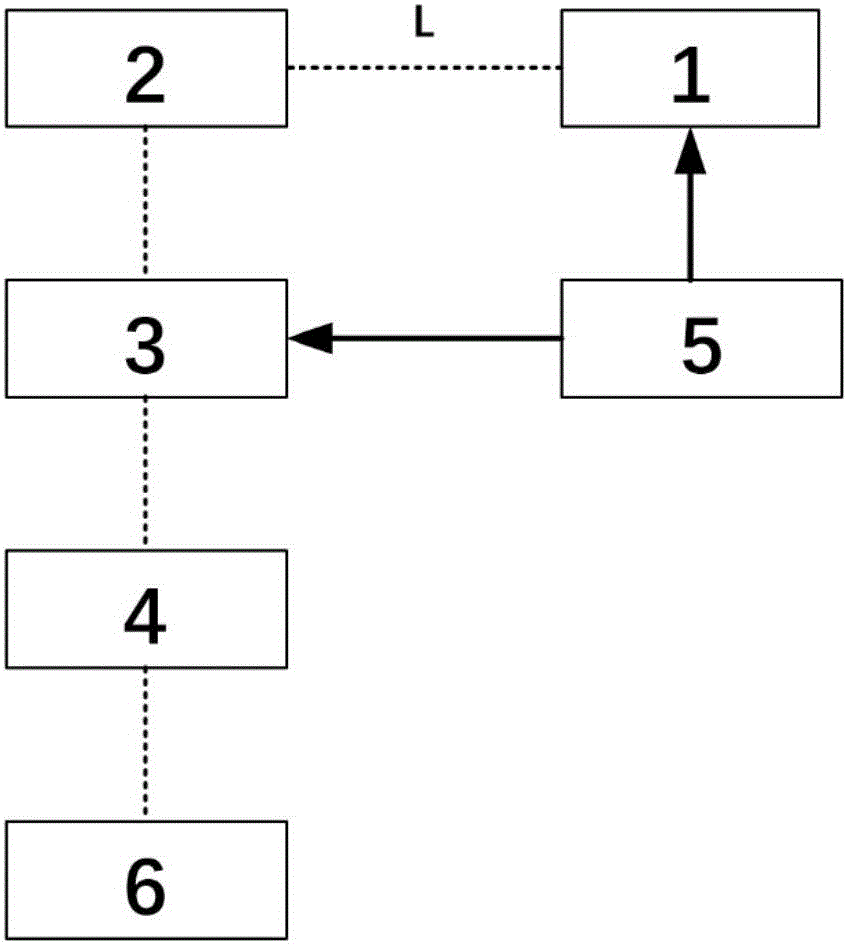

[0020] Such as figure 1 As shown, an anti-damage laser cleaning device in this embodiment includes a laser 1, a beam shaping system 2, a scanning galvanometer 3, a focusing system 4 and a control system 5;

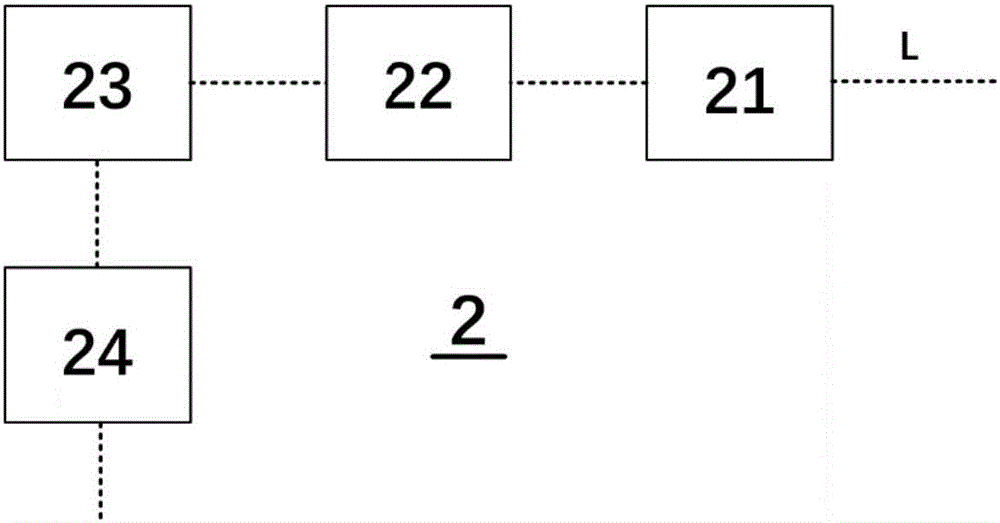

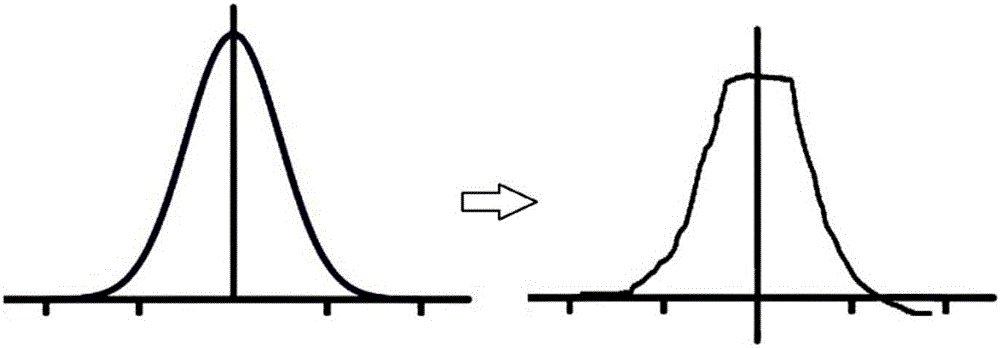

[0021] The beam shaping system 2 is arranged in the laser light path L, and is used to shape the laser beam, such as figure 2 As shown, it includes a beam expanding unit 21, a flat top beam transformation unit 22, a uniform beam transformation unit 23 and a polarization analysis unit 24; as image 3 As shown, the laser light passes through the beam expanding unit 21 and the flat-hat beam conversion unit 22 in turn, the laser beam of the original Gaussian waveform is shaped into a flat-hat beam waveform, and then passes through the uniform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com