Assembly device for pressure steel pipes

A technology for penstocks and assembling devices, which is applied to auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of pressure steel pipe quality impact, complex cutting and treatment measures, etc., achieve high construction efficiency and reduce worker labor The effect of high strength and high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

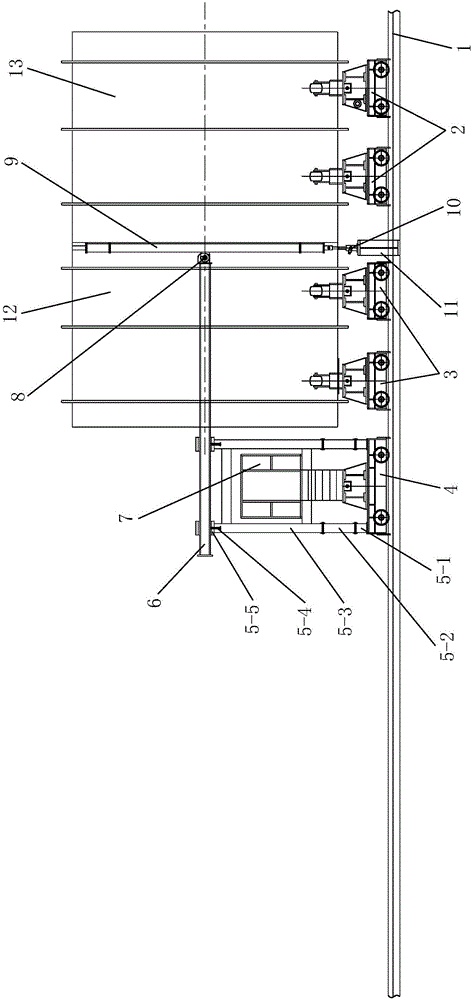

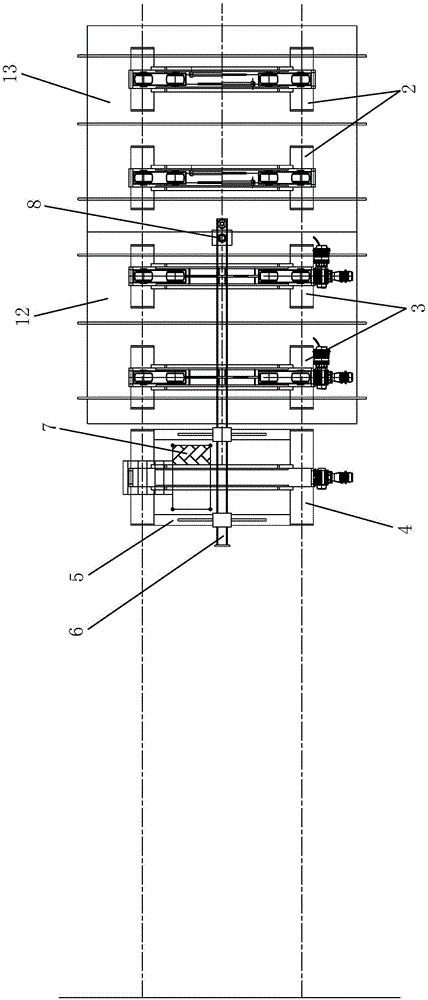

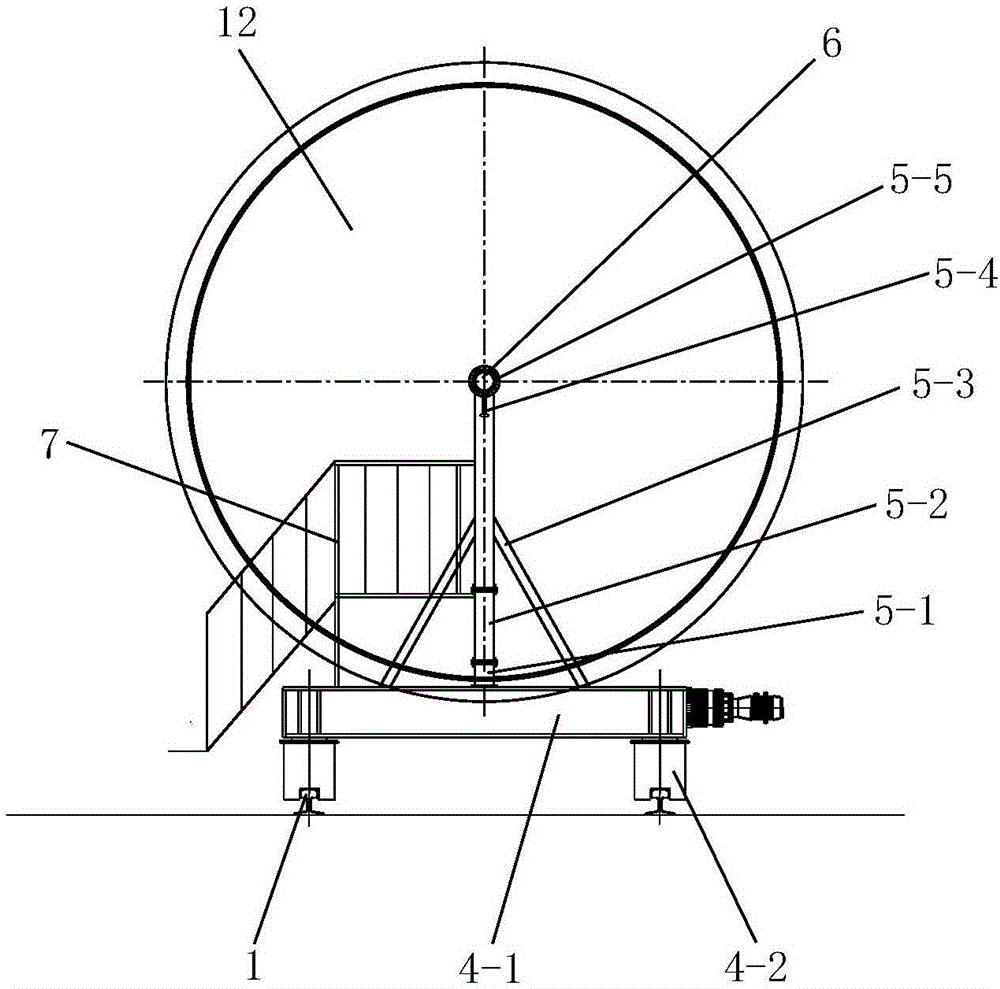

[0043] Such as figure 1 and figure 2 As shown, the present invention includes a fixed trolley 2, a mobile trolley 3 and a mobile assembly trolley 4 arranged on the track 1 in sequence, the fixed trolley 2 is fixedly connected to the track 1, the mobile trolley 3 and the mobile assembly The trolleys 4 are all slidingly connected with the track 1, the fixed trolley 2 and the mobile trolley 3 are roll welding trolleys, the mobile assembly trolley 4 is equipped with an assembly support mechanism 5 and an operating platform 7, and the assembly The support mechanism 5 is provided with an assembled horizontal mechanism 6 that can move horizontally on the assembled support mechanism 5 and can be locked. The rounding column mechanism 9 of the rounding column mechanism 9 is provided with a steel pipe outer support 11, the first hydraulic jack 10 is installed on the steel pipe outer support 11, and the steel pipe outer support 11 is located between the fixed trolley 2 and Move the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com