Stacked type propeller manufacturing method

A production method and propeller technology, applied in image data processing, 3D modeling, instruments, etc., can solve problems such as limiting the development of ship propellers, low controllability, and process difficulties, so as to enhance autonomy, reduce restrictions, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the features of the present invention in detail, it is illustrated as follows with accompanying drawings:

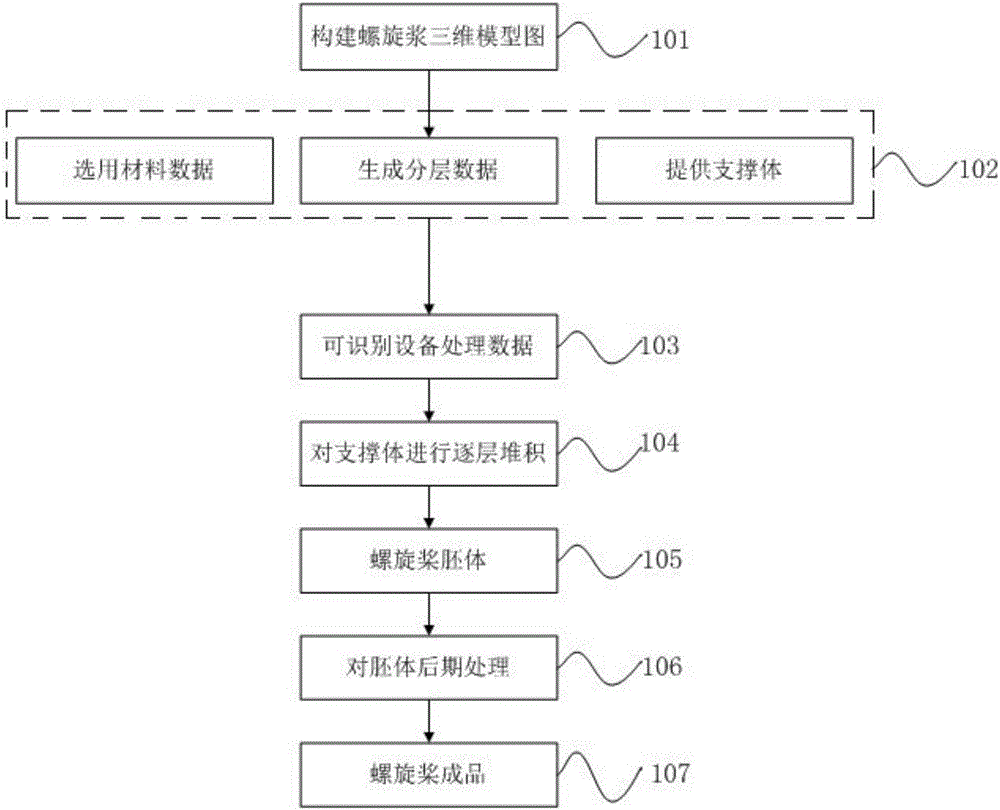

[0024] Such as figure 1 As shown, the present invention provides a method for manufacturing a stacked propeller, which comprises the following steps:

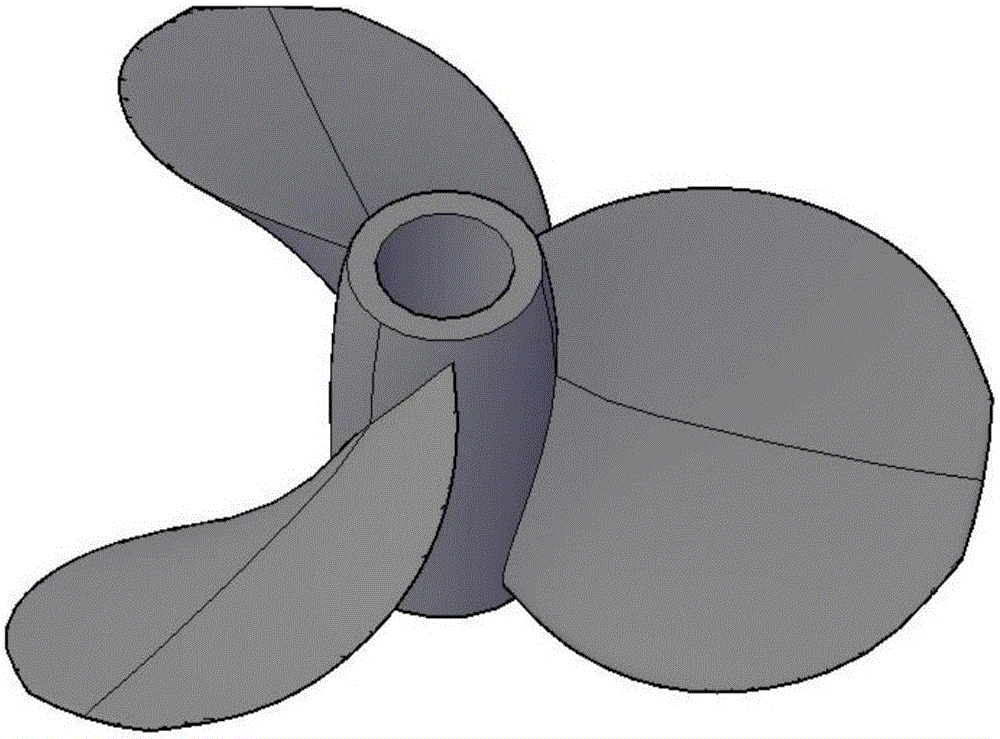

[0025] 101 in the figure illustrates that the present invention uses computer-aided software to construct a three-dimensional model diagram of the propeller; in practice, using the present invention to make a three-bladed ship propeller requires drawing a three-dimensional model diagram with a ratio of 1:1 in CAD and other drawing tools.

[0026] 102 in the figure shows that the format conversion of the three-dimensional model diagram of the propeller to generate the layered data of the propeller is input into the identifiable device, and at the same time, the material data for making the propeller is input into the identifiable device. ; At this time, the propeller support body can also be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com