Self-sealing oil tank

A self-sealing, fuel tank technology, applied in the fuel tank, substructure, coating and other directions of the power unit, can solve the problems of lack of contact with the sealing layer, easy fuel leakage, hazards, etc., to ensure the sealing effect and improve the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of self-sealing fuel tank of the present invention:

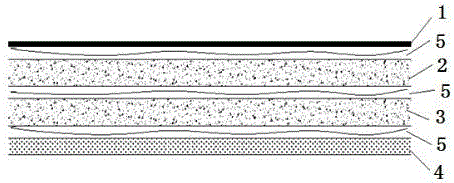

[0043] The woven base cloth substrate is coated with molten colloid formed at a high temperature of 230° C., thereby forming an upper primer layer and a lower primer layer on the upper and lower sides of the substrate, forming a rubber-coated fabric 6 . Then the prepared first sealing layer 2 and the second sealing layer 3 are pasted on the rubber-coated fabric 6, and then the same rubber-coated fabric 6 is pasted on the exposed surfaces of the first sealing layer 2 and the second sealing layer 3 , and then apply an outer coat 1 on the top, and finally stick an oil-diffusion-proof layer 4 on the bottom. The bonding process is all high temperature compaction process. This process is prior art and can be performed using conventional methods.

Embodiment 1

[0045]A self-sealing oil tank according to the present invention comprises a box body composed of plates; wherein, the plate body sequentially includes an outer coating, a rubber-coated fabric layer, a first sealing layer, a rubber-coated fabric layer, second sealing layer, rubber-coated fabric layer and oil diffusion barrier;

[0046] Specifically, the outer coating includes neoprene, antioxidant, vulcanizing agent, accelerator and zinc oxide; and neoprene: antioxidant, vulcanizing agent, accelerator, the mass ratio of zinc oxide is 7:1:0.4: 1.6.

[0047] Wherein, the antioxidant is a mixture of N,N-dibenzylhydroxylamine and alkyldiphenylamine, and the mass ratio of N,N-dibenzylhydroxylamine:alkyldiphenylamine is 1:1.

[0048] Specifically, the first sealing layer and the second sealing layer are sealing layers of the same material, including natural rubber: polybutylene rubber and dicumyl peroxide, and the natural rubber: polybutylene rubber: The mass ratio of dicumyl pero...

Embodiment 2

[0055] A self-sealing oil tank, including a box body composed of plates; wherein, the plate body sequentially includes an outer coating, a rubber-coated fabric layer, a first sealing layer, a rubber-coated fabric layer, and a second Sealing layer, rubber-coated fabric layer and oil diffusion-resistant layer;

[0056] Specifically, the outer coating includes neoprene, antioxidant, vulcanizing agent, accelerator and zinc oxide; and neoprene: antioxidant, vulcanizing agent, accelerator, the mass ratio of zinc oxide is 7:1:0.4: 1.6.

[0057] Wherein, the antioxidant is a mixture of N,N-dibenzylhydroxylamine and alkyldiphenylamine, and the mass ratio of N,N-dibenzylhydroxylamine:alkyldiphenylamine is 1:1.

[0058] Specifically, the first sealing layer and the second sealing layer are sealing layers of the same material, including natural rubber: polybutylene rubber and dicumyl peroxide, and the natural rubber: polybutylene rubber: The mass ratio of dicumyl peroxide is 7:2:1.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com