Quick disconnect attachment system, parachute system, attachment and disconnection method

A connection system and fast detachment technology, applied in the field of parachute systems, can solve problems such as poor safety, poor versatility, and complex structure, and achieve the effects of simple structure, cost saving, and increased detachment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

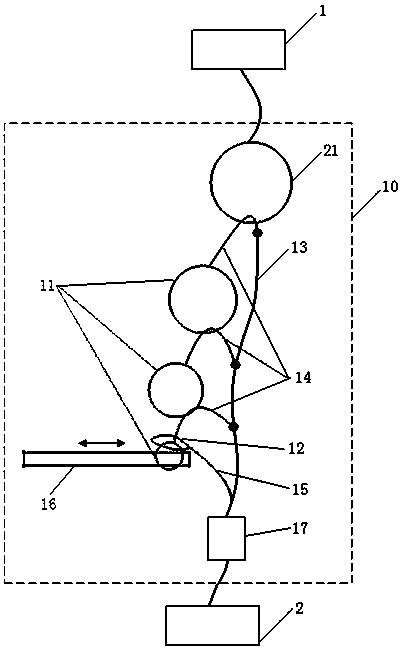

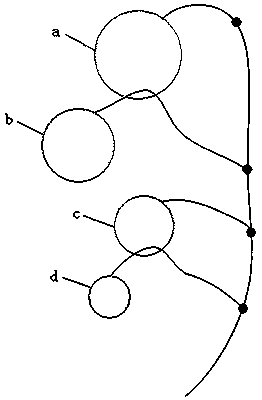

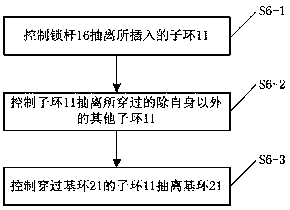

[0051] This embodiment provides a quick-disengageable connection system, which can be applied to any required system, and is especially suitable for the connection between a flying device (such as a drone) and a parachute. like figure 1 As shown, a quick-disconnect connection system 10 is used for connecting a first to-be-connected part 1 and a second to-be-connected part 2 . The quick disconnect connection system 10 comprises: a base ring 21, at least two sub-rings 11 ( figure 1 Three sub-rings 11) and locking bar 16 are shown in . The base ring 21 is used for connecting with the first component to be connected. The sub-ring 11 is connected to the first connecting band 13 through the second connecting band 14, the first connecting band 13 is connected to the second part to be connected, and the sub-ring 11 passes through the hole in the middle of the base ring 21 or any The hole in the middle of other sub-rings 11. The locking rod 16 is used for inserting into the hole in...

Embodiment 2

[0060] This embodiment provides a quick-disconnect connection system, in addition to including the components of Embodiment 1 above, such as Figure 4 As shown, a clasp 12 is also included. The buckle 12 is connected to the first connecting belt 13 through the third connecting belt 15 , and the buckle 12 is used to pass through the sub-ring 11 where the locking rod 16 is inserted during connection. The clasp 12 can be set through one sub-ring, and can also be set through a plurality of sub-rings. By setting the clasp, when connecting, the clasp is put through the sub-ring first, and then the locking rod is inserted into the sub-ring, thereby further ensuring the reliability of the connection and improving the firmness of the connection system.

Embodiment 3

[0062] This embodiment provides a quick disconnect connection system, in addition to including the components of Embodiments 1 and 2 above, such as Figure 5 As shown, it also includes a retractable belt device 17 (such as a pulley, etc.). The first connecting belt 13 is connected to the second to-be-connected part 2 through a retractable belt device 17 , and the retractable belt device 17 is used to increase or shorten the length of the first connecting belt 13 . When detaching, the control system can control the retractable belt device 17 to tighten the first connecting belt 13, shorten the length of the first connecting belt 13, and achieve the purpose of quickly extracting the ion ring, thereby further improving the detachment speed of the connecting system. The advantage of a quick breakaway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com