Lifting mechanism and lifting system based on lifting mechanism for large structural part

A technology for large-scale structural parts and hoisting systems, which is applied to portable hoisting devices, hoisting devices, etc., can solve the problems of many limitations, high costs, and high requirements for hoisting conditions for crane hoisting, and achieves low installation environment requirements. Point position easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

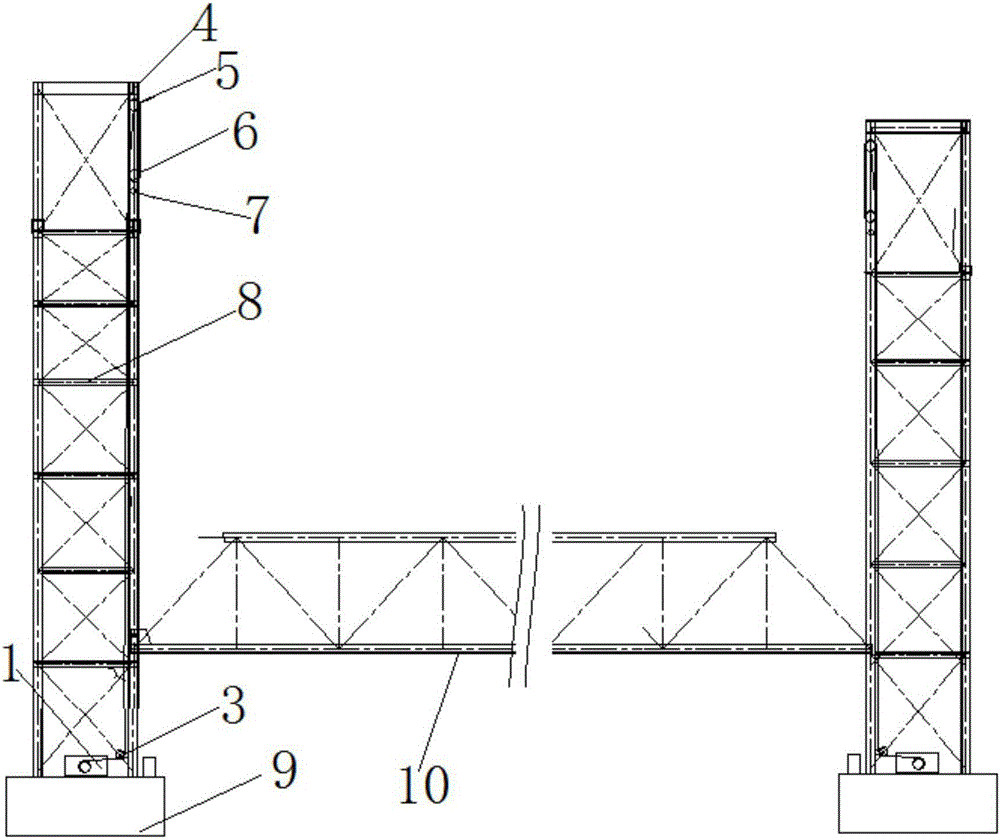

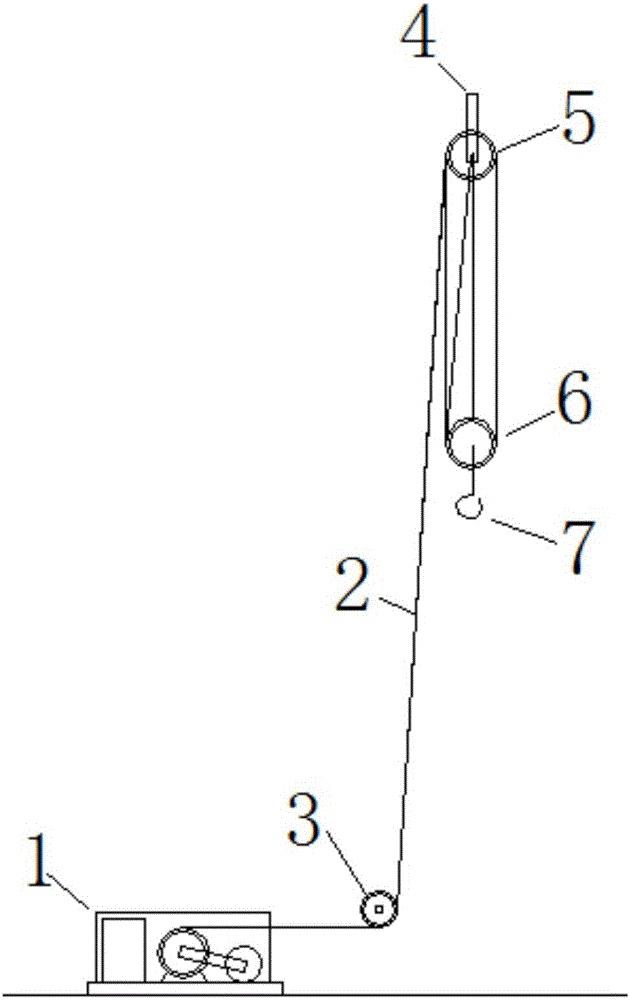

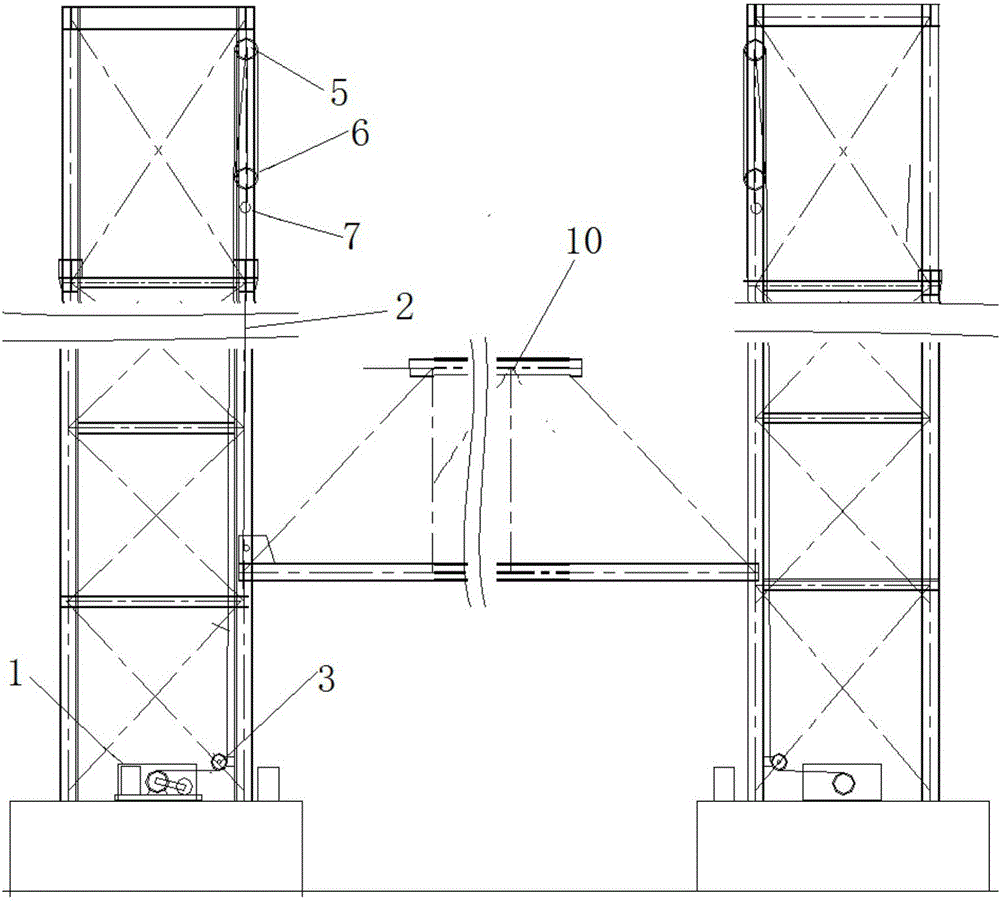

[0045] A lifting mechanism of this embodiment, such as figure 2 Shown, comprise the pulley group that fixed pulley 5 and movable pulley 6 form, also comprise the pull-up mechanism 1 of low position and the auxiliary hanger 4 of high position; The lifting mechanism 1 passes through the pulley block chute by the traction line to drive the driving pulley 6 to lift the weight and rise. The hoisting mechanism of this embodiment is a hoisting mechanism that does not require the use of a crane. When this mechanism is installed without the need for a crane, it is only necessary to fix the lifting mechanism 1 at a low position and the auxiliary hanger 4 at a high position. Realize the purpose of lifting heavy objects such as large steel structures and reinforced concrete components, with strong mobility and low requirements for the installation environment on the processing site.

Embodiment 2

[0047] A lifting mechanism of this embodiment, the specific structure is basically the same as that of Embodiment 1, and the improvement is that the number of fixed pulleys 5 and movable pulleys 6 in the pulley block is the same, which can be three, and correspond to each other, and can be combined. The shape and weight of large structural parts are configured accordingly, and the characteristics of large structural parts, good symmetry, and easy configuration of the position of the pulley blocks can achieve mutual synergistic technical effects. Can also include guide pulley 3, the traction line of pulling mechanism 1 passes through guide pulley 3 chute first, and then works on the pulley block, can coordinate the position of pulley block and pulling mechanism according to the situation on the spot, further improves the flexibility of lifting mechanism and Versatility.

Embodiment 3

[0049] A lifting mechanism of this embodiment and a lifting system for large structural parts based on the mechanism, such as figure 1 , 3 As shown, it is applied to the 4# blast furnace project of a steel plant, the steel corridor is 30t, the span is 40m, and the lifting height is 15m, such as Figure 5 , 6 As shown, 4 sets of this lifting mechanism are adopted, and the basic structure of the lifting mechanism is the same as that of embodiment 2. The improvement is that the lifting mechanism 1 is a winch, so as to improve the lifting height of the whole mechanism to the heavy object, which can be any height in theory. Moreover, the maneuverability is strong; the guide pulley 3 is fixed in the horizontal direction of the hoist, directly below the pulley block, and the force direction of the traction line is turned to be vertically downward, and the pulley block is pulled to avoid oblique pulling and shaking, and achieve a smooth lifting effect ; Realize the maximization of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com